The integration of IC (Integrated Circuit) boards and their components is central to modern electronics. IC boards, often referred to as PCBs (Printed Circuit Boards), serve as the backbone for most electronic devices, providing the physical and electrical connections needed for various components to communicate and function. This article delves into the essential components found on IC boards, their functions, and their importance in electronics.

The Basics of IC Boards

IC boards are flat, often green, boards made of non-conductive materials such as fiberglass or plastic. These boards have conductive pathways etched or printed onto them, allowing electricity to flow between different components. The primary purpose of an IC board is to connect various electronic components in a reliable and organized manner.

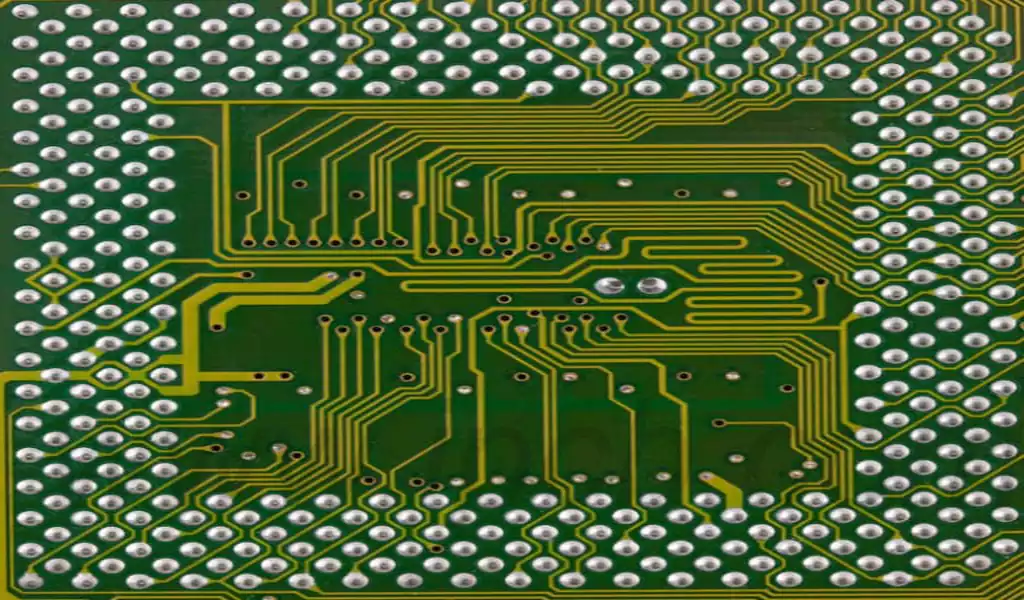

Conductive Pathways

The conductive pathways, or traces, on an IC board are usually made of copper. These traces are essential for creating a circuit by connecting different components. The design and layout of these pathways are crucial, as they determine the efficiency and functionality of the circuit. The traces must be designed to minimize interference and ensure that signals are transmitted without loss or distortion.

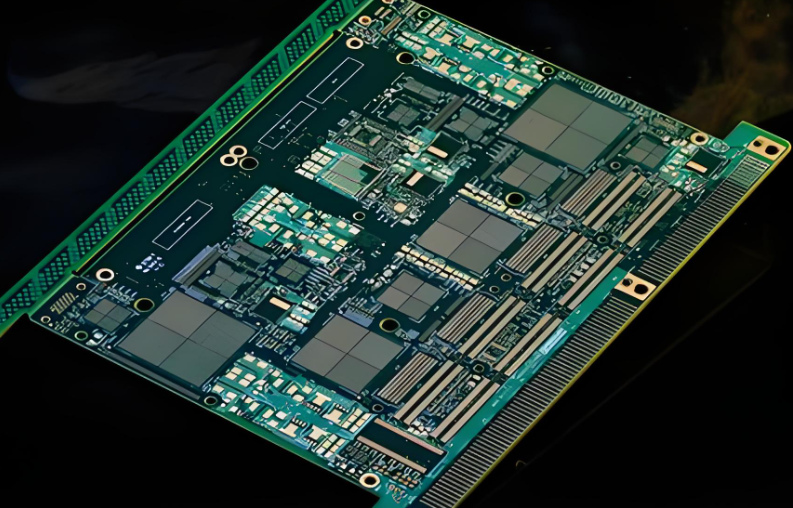

Layers of IC Boards

IC boards can be single-layered or multi-layered. Single-layered boards have conductive pathways on one side, while multi-layered boards have multiple layers of pathways separated by insulating materials. Multi-layered boards are common in complex electronics, as they allow for more connections and reduce the size of the board.

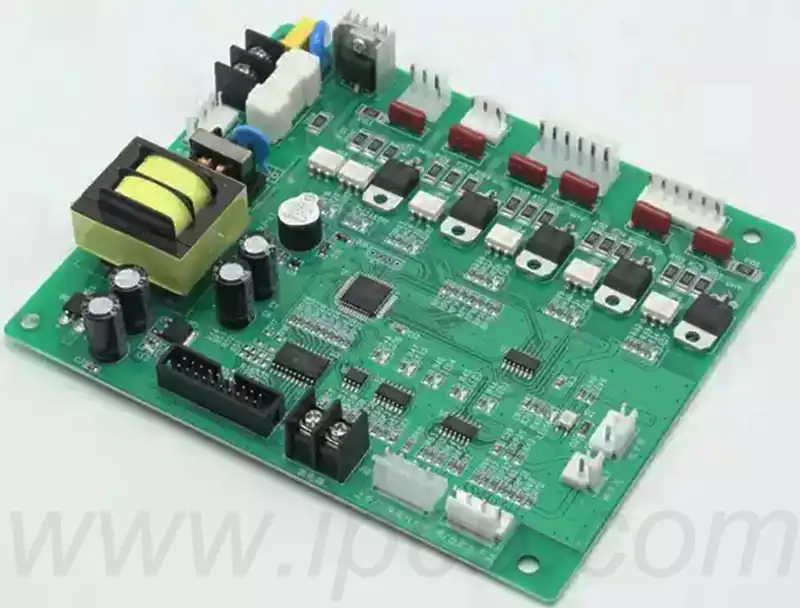

Essential Components on IC Boards

Various components are mounted on IC boards to create functional circuits. Each component has a specific role, and the proper integration of these components is essential for the overall performance of the device.

Resistors

Resistors are one of the most fundamental components on an IC board. They limit the flow of electric current, protecting other components from excessive current that could cause damage. Resistors are used in various applications, including controlling signal levels, dividing voltages, and biasing active elements.

Capacitors

Capacitors store and release electrical energy. They are used for filtering, timing, and energy storage in electronic circuits. Capacitors can smooth out fluctuations in power supply, ensuring stable operation of the circuit. They are also crucial in tuning circuits, such as in radio frequency (RF) applications, to select specific frequencies.

Inductors

Inductors are components that store energy in a magnetic field when electrical current flows through them. They are often used in power supply circuits to filter out noise and provide smooth power delivery. Inductors are also essential in RF applications, where they work alongside capacitors to form tuned circuits.

Diodes

Diodes allow current to flow in one direction only, making them essential for controlling the direction of current flow in a circuit. They are used in various applications, including rectification, voltage regulation, and signal demodulation. One common type of diode is the Light Emitting Diode (LED), which emits light when current flows through it.

Transistors

Transistors are semiconductor devices used to amplify or switch electronic signals. They are the building blocks of modern electronic devices and are found in almost every circuit. Transistors can function as amplifiers, oscillators, and switches, making them versatile and essential components.

Integrated Circuits (ICs)

Integrated Circuits are complex assemblies of multiple electronic components, such as transistors, resistors, and capacitors, all embedded into a single silicon chip. ICs perform various functions, from simple logic operations to complex signal processing. They are the heart of modern electronics, enabling the miniaturization and sophistication of devices.

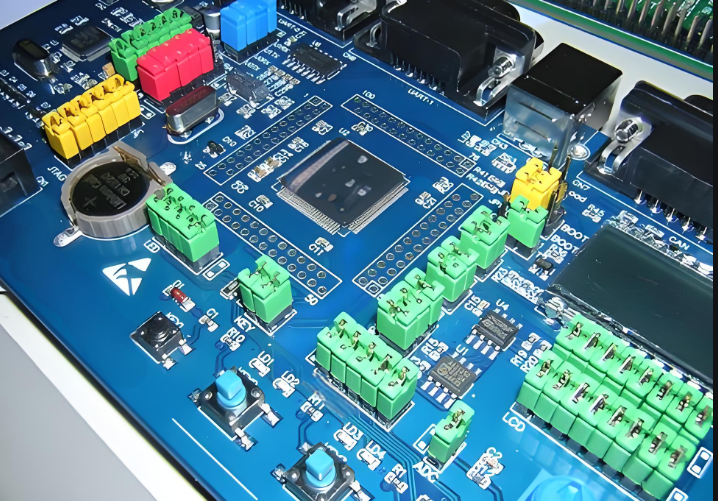

Connectors

Connectors provide the interface between the IC board and external devices or other boards. They ensure reliable electrical connections and allow for easy assembly and disassembly of electronic systems. Common types of connectors include pin headers, USB ports, and HDMI connectors.

Specialized Components on IC Boards

In addition to the basic components, many specialized components are used on IC boards to perform specific functions.

Microcontrollers

Microcontrollers are small computers on a single chip, containing a processor, memory, and input/output peripherals. They are used in a wide range of applications, from simple devices like remote controls to complex systems like automotive control units. Microcontrollers provide the intelligence to control various functions and processes.

Sensors

Sensors are components that detect physical quantities, such as temperature, light, or pressure, and convert them into electrical signals. They are used in various applications, including environmental monitoring, medical devices, and industrial automation. Sensors enable electronic systems to interact with the physical world.

Oscillators

Oscillators generate periodic signals, often used as clock signals in digital circuits. They ensure that operations in electronic systems occur in a synchronized manner. Oscillators are crucial in applications requiring precise timing, such as communication systems and microprocessors.

Transformers

Transformers are used to transfer electrical energy between circuits through electromagnetic induction. They can increase (step-up) or decrease (step-down) voltage levels, making them essential in power supply circuits. Transformers also provide isolation between circuits, enhancing safety and reliability.

Relays

Relays are electromechanical switches used to control high-power devices with low-power signals. They are commonly used in applications requiring electrical isolation and high current handling, such as industrial control systems and automotive electronics.

The Role of IC Boards in Electronics

IC boards are integral to the functioning of modern electronic devices. They provide a platform for mounting and interconnecting various components, enabling complex circuits to perform desired functions. The design and manufacturing of IC boards are critical to the performance, reliability, and longevity of electronic devices.

Design Considerations

The design of an IC board involves careful planning and consideration of various factors, including the placement of components, routing of traces, and thermal management. Proper design ensures that the board operates efficiently and reliably under different conditions.

Manufacturing Process

The manufacturing process of IC boards includes several steps, such as printing the circuit layout, etching the traces, drilling holes for component leads, and soldering the components onto the board. Advanced techniques, such as surface-mount technology (SMT) and automated assembly, enhance the precision and efficiency of the manufacturing process.

Quality Control

Quality control is crucial in the production of IC boards to ensure that they meet the required specifications and standards. Testing procedures, such as electrical testing, inspection, and functional testing, are implemented to identify and rectify any defects or issues.

Advances in IC Board Technology

The field of IC board technology is continually evolving, driven by the need for smaller, faster, and more efficient electronic devices. Several advances have been made in materials, design techniques, and manufacturing processes.

High-Density Interconnect (HDI) Boards

HDI boards are designed with higher wiring density per unit area, allowing more components to be placed on the board. This results in smaller and more compact devices without compromising performance. HDI technology is widely used in smartphones, tablets, and other portable electronics.

Flexible PCBs

Flexible PCBs are made of flexible materials, allowing them to bend and conform to different shapes. They are used in applications where space is limited, and the board needs to fit into non-flat or irregular surfaces. Flexible PCBs are commonly found in wearable devices, medical implants, and automotive applications.

Advanced Materials

The use of advanced materials, such as high-frequency laminates and low-loss dielectrics, has improved the performance of IC boards in high-speed and high-frequency applications. These materials reduce signal loss and interference, ensuring reliable operation in demanding environments.

3D Printing

3D printing technology has opened new possibilities in the design and production of IC boards. It allows for the creation of complex and customized board designs that are difficult to achieve with traditional manufacturing methods. 3D-printed IC boards offer greater design flexibility and faster prototyping.

IC Board Applications in Various Industries

IC boards are ubiquitous in numerous industries, each leveraging the unique advantages offered by these versatile components.

Consumer Electronics

The consumer electronics industry is perhaps the most visible user of IC boards. Smartphones, tablets, laptops, and televisions all rely on PCBs to function. The miniaturization of components and the use of HDI technology have enabled manufacturers to produce smaller, lighter, and more powerful devices. High-performance processors, memory chips, and intricate circuitry work together on these boards to deliver the functionality consumers expect.

Automotive Industry

In the automotive industry, IC boards are critical for both performance and safety. Modern vehicles contain numerous electronic control units (ECUs) that manage everything from engine performance and emissions to braking systems and infotainment. Advanced driver-assistance systems (ADAS) and autonomous driving technologies also depend on reliable and robust IC boards to process data from various sensors and cameras, ensuring safe and efficient vehicle operation.

Medical Devices

Medical devices such as pacemakers, defibrillators, imaging equipment, and diagnostic tools incorporate IC boards to deliver precise and reliable performance. In these applications, the reliability and durability of PCBs are paramount, as device failure can have serious consequences. Medical PCBs often require special coatings and materials to withstand harsh environments and ensure patient safety.

Industrial Automation

Industrial automation systems rely on IC boards to control machinery, manage production lines, and monitor processes. These systems often operate in challenging environments where durability and reliability are critical. IC boards used in industrial applications must be able to withstand high temperatures, moisture, and mechanical stress while maintaining precise control over operations.

Telecommunications

The telecommunications industry depends heavily on IC boards for infrastructure and devices. Network equipment such as routers, switches, and base stations require high-speed and high-frequency PCBs to manage data transmission and connectivity. As the demand for faster and more reliable communication grows, the need for advanced PCB technology continues to rise.

Aerospace and Defense

Aerospace and defense applications demand the highest levels of performance and reliability from IC boards. These boards must function flawlessly under extreme conditions, including high temperatures, radiation, and mechanical shock. Military and aerospace systems use PCBs in avionics, communication systems, navigation, and missile guidance, where failure is not an option.

Future Trends in IC Board Technology

As technology continues to evolve, several trends are shaping the future of IC board technology. These trends aim to address the growing demand for more powerful, efficient, and versatile electronic devices.

Miniaturization

The trend towards miniaturization is driving the development of smaller, more densely packed IC boards. Advances in HDI technology, component packaging, and manufacturing processes enable the creation of compact devices without sacrificing performance. This trend is particularly evident in wearable technology, IoT devices, and portable electronics.

Internet of Things (IoT)

The IoT revolution is increasing the demand for IC boards designed for connectivity, low power consumption, and reliability. IoT devices require PCBs that can handle wireless communication, sensors, and power management while maintaining a small form factor. The integration of IoT technology into various applications, from smart homes to industrial automation, is driving innovation in PCB design.

Advanced Materials

The use of advanced materials is enhancing the performance of IC boards in high-speed and high-frequency applications. Materials such as ceramic substrates, high-frequency laminates, and thermal management solutions are improving signal integrity, reducing losses, and increasing reliability. These materials are crucial for applications such as 5G communication, aerospace, and high-performance computing.

Environmental Considerations

Environmental sustainability is becoming increasingly important in the electronics industry. Efforts to reduce the environmental impact of IC board manufacturing include the use of eco-friendly materials, recycling of electronic waste, and the development of energy-efficient processes. Manufacturers are also exploring ways to reduce the use of hazardous substances and improve the overall sustainability of their products.

Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are influencing IC board design and manufacturing. AI and ML algorithms can optimize PCB layouts, improve manufacturing processes, and predict potential failures. These technologies enable more efficient and reliable production, enhancing the performance and longevity of IC boards.

Conclusion

IC board components are the building blocks of modern electronic devices. Understanding their functions and interactions is crucial for designing and manufacturing efficient and reliable circuits. As technology continues to advance, IC boards and their components will play an increasingly important role in shaping the future of electronics. The integration of advanced materials, miniaturization, IoT, and AI/ML technologies will drive innovation, making electronic devices more powerful, efficient, and versatile. By staying abreast of these trends and developments, manufacturers and designers can continue to push the boundaries of what is possible with IC boards, creating a future where electronics are seamlessly integrated into every aspect of our lives.