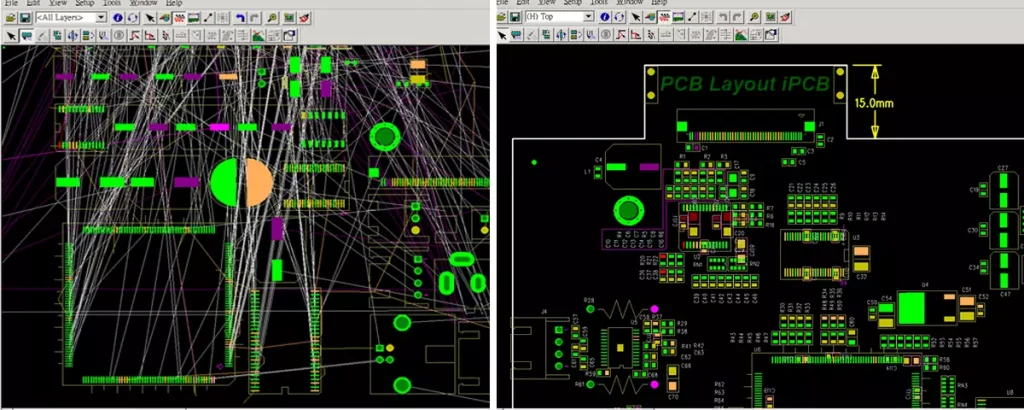

Arlon Electronic Materials is a distinguished name in the realm of high-performance electronic materials, particularly within the domain of printed circuit boards (PCBs). The company’s extensive portfolio and commitment to innovation make it a key player in the electronics industry. This article delves into Arlon’s product offerings, their impact on various sectors, and the technological advancements that set them apart. By focusing on the multifaceted aspects of Arlon Electronic Materials, this overview aims to provide a comprehensive understanding of their significance in modern electronics.

Introduction to Arlon Electronic Materials

Arlon Electronic Materials has established itself as a leading provider of high-quality materials essential for the fabrication of PCBs. The company’s products are integral to a wide range of applications, from consumer electronics to complex aerospace and defense systems. Arlon’s dedication to quality and innovation has solidified its position as a pivotal contributor to the electronics industry. Their materials are recognized for their exceptional performance, reliability, and ability to meet the increasing demands of modern electronics.

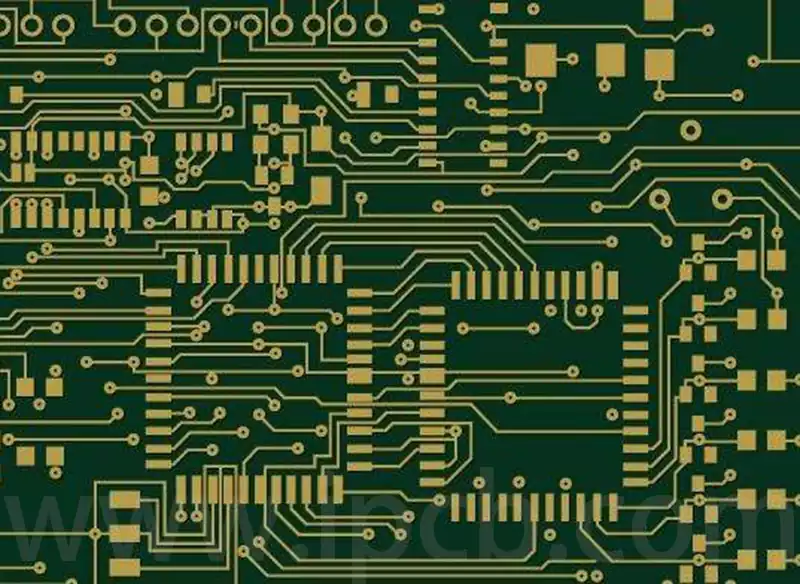

Product Portfolio

Arlon’s diverse product portfolio is designed to address various needs within the PCB industry. The company offers an array of high-performance materials, including high-frequency laminates, advanced dielectric materials, and thermally conductive materials. Each product is meticulously engineered to provide specific benefits, such as enhanced signal integrity, superior thermal management, and mechanical stability.

- High-Frequency Laminates

High-frequency laminates are a cornerstone of Arlon’s product line. These materials are engineered to handle signals at microwave and millimeter-wave frequencies, making them essential for applications in telecommunications, radar systems, and satellite communications. The performance of these laminates is critical in maintaining signal integrity and minimizing loss or distortion. Arlon’s high-frequency laminates are known for their excellent dielectric properties, including a low loss tangent and high thermal stability. These characteristics ensure that signals are transmitted with minimal interference, which is crucial for high-speed and high-frequency applications.

Arlon’s commitment to quality is reflected in their meticulous testing and manufacturing processes. Each laminate undergoes rigorous testing to ensure it meets industry standards and customer specifications. This attention to detail is what sets Arlon apart from competitors and makes their high-frequency laminates the preferred choice for demanding applications. Furthermore, the company’s ongoing research and development efforts are focused on continually improving the performance of these laminates, ensuring that they remain at the forefront of technological advancements.

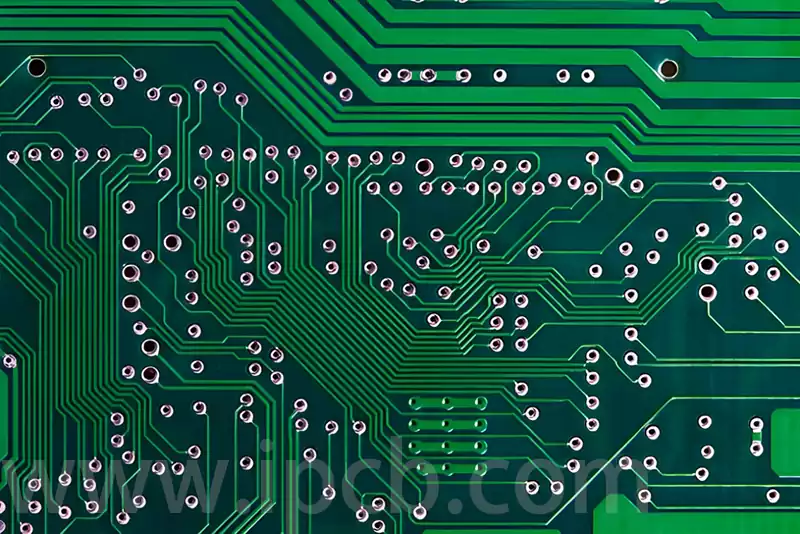

- Advanced Dielectric Materials

Advanced dielectric materials from Arlon are designed for applications requiring high electrical insulation and mechanical strength. These materials are particularly well-suited for high-density interconnects and multilayer PCBs, where precise electrical performance and durability are paramount. Arlon’s advanced dielectrics offer a low dielectric constant and low dissipation factor, which contribute to improved signal performance and reduced energy loss. These materials are essential in sophisticated electronic systems where stable and reliable performance is required.

Arlon’s dielectric materials are also highly adaptable, making them suitable for a wide range of applications. Whether used in automotive systems, medical devices, or industrial control systems, these materials provide the necessary insulation and stability to ensure optimal performance. Arlon’s engineers work closely with customers to tailor dielectric materials to specific project needs, offering customized solutions that address unique challenges in electronic design and manufacturing.

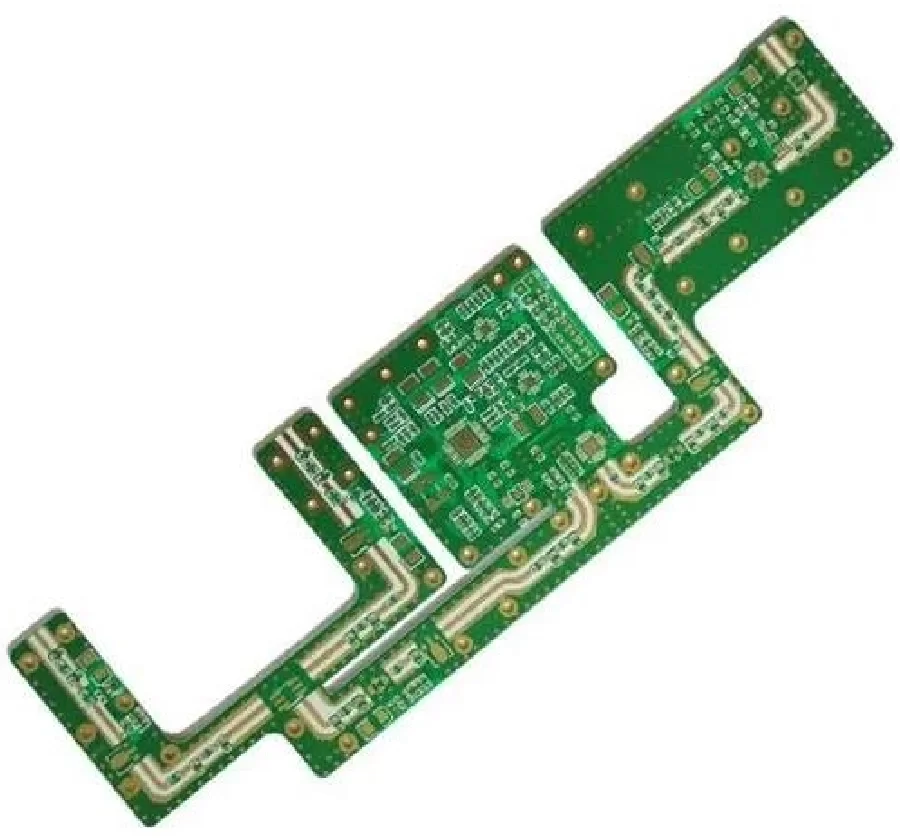

- Thermally Conductive Materials

Effective thermal management is crucial for the performance and longevity of electronic devices. Arlon’s thermally conductive materials are engineered to manage heat generated by electronic components efficiently. These materials provide excellent heat transfer while maintaining electrical insulation. This capability is especially important in high-power and high-density applications, where overheating can lead to performance issues and reduced lifespan of electronic components. By offering superior thermal management, Arlon’s materials help ensure that electronic devices operate reliably and efficiently under demanding conditions.

Arlon’s thermally conductive materials are not only effective but also versatile. They are used in a variety of applications, from power electronics to LED lighting systems, where heat dissipation is a critical factor. The materials are designed to work seamlessly with other components, ensuring that they do not interfere with the electrical performance of the device. Additionally, Arlon is constantly exploring new ways to enhance the thermal conductivity of their materials, focusing on innovative approaches that push the boundaries of what is possible in thermal management.

Applications of Arlon Electronic Materials

The versatility of Arlon Electronic Materials allows them to be used in a wide range of applications. Their products are integral to various sectors, including consumer electronics, aerospace and defense, automotive, and industrial applications. Each sector benefits from the unique properties of Arlon’s materials, which contribute to the performance, reliability, and efficiency of electronic systems.

Consumer Electronics

In the consumer electronics sector, Arlon’s high-frequency laminates and advanced dielectrics play a significant role in enhancing the performance of devices such as smartphones, tablets, and laptops. These materials help improve signal clarity, reduce interference, and ensure reliable operation of electronic components. For example, high-frequency laminates enable efficient data transmission in smartphones and tablets, while advanced dielectrics help minimize signal loss within these devices. The performance characteristics of Arlon’s materials are critical in meeting the high expectations of modern consumer electronics, contributing to their overall functionality and quality.

Moreover, as consumer electronics continue to evolve, the demand for more compact and powerful devices grows. Arlon’s materials are at the forefront of this evolution, providing the necessary performance enhancements that allow manufacturers to produce smaller, faster, and more reliable devices. The ability to pack more functionality into a smaller space without compromising performance is one of the key advantages of using Arlon’s materials in consumer electronics.

Aerospace and Defense

Aerospace and defense applications demand the highest levels of performance and reliability from electronic components. Arlon’s materials are extensively used in radar systems, communication devices, and satellite technology, where signal integrity and durability are crucial. High-frequency laminates are employed to ensure accurate and reliable operation of these systems, while thermally conductive materials manage heat in high-power applications. The robustness of Arlon’s products makes them well-suited for the rigorous demands of aerospace and defense environments, where performance and reliability are of utmost importance.

The aerospace and defense sectors also require materials that can withstand extreme environmental conditions, such as high altitudes, temperature fluctuations, and intense mechanical stress. Arlon’s materials are designed to perform under these challenging conditions, ensuring that electronic systems remain operational and effective. The company’s commitment to quality and innovation has made Arlon a trusted supplier to leading aerospace and defense organizations worldwide.

Automotive Industry

The automotive industry increasingly relies on advanced electronics for various systems, including infotainment, advanced driver-assistance systems (ADAS), and engine control units (ECUs). Arlon’s advanced dielectric materials and thermal management solutions are essential for ensuring the reliable operation of these systems. In ADAS systems, for example, high-frequency laminates facilitate high-speed data processing and communication, while thermally conductive materials help manage heat generated by high-power components. The performance and reliability of automotive electronics are greatly enhanced by Arlon’s materials, contributing to the overall safety and functionality of modern vehicles.

In addition to performance, the automotive industry is also focused on sustainability and energy efficiency. Arlon’s materials contribute to these goals by enabling the development of lightweight, energy-efficient electronic systems that reduce the overall carbon footprint of vehicles. As electric and autonomous vehicles become more prevalent, the demand for advanced materials that can support these technologies will continue to grow, positioning Arlon as a key player in the future of automotive electronics.

Industrial Applications

Arlon’s electronic materials are also used in industrial applications, such as manufacturing equipment and industrial control systems. The ability to handle high frequencies, provide electrical insulation, and manage heat is critical in these environments. Advanced dielectrics from Arlon help maintain precise control over electrical signals, while thermally conductive materials ensure efficient heat management. These properties contribute to the efficient operation and longevity of industrial electronics, improving system performance and reliability in demanding industrial settings.

Industrial applications often involve harsh conditions, including exposure to chemicals, extreme temperatures, and high levels of mechanical stress. Arlon’s materials are engineered to withstand these challenges, providing reliable performance even in the most demanding environments. This durability makes Arlon’s products an ideal choice for industrial applications where long-term reliability is essential.

Technological Advancements

Arlon Electronic Materials is committed to advancing technology and enhancing the performance of their products. The company invests in research and development to create innovative solutions that address the evolving needs of the electronics industry.

Innovations in Dielectric Materials

Arlon continually works on developing new dielectric materials with improved properties. Innovations in this area include enhancements in dielectric constant and loss tangent, which are critical for high-speed and high-frequency applications. These advancements help ensure that Arlon’s materials meet the growing demands of modern electronics by providing better signal integrity and reduced energy loss. Research in dielectric materials focuses on improving performance while maintaining cost-effectiveness, allowing Arlon to offer cutting-edge solutions that drive technological progress in the electronics industry.

In addition to performance improvements, Arlon is also exploring new material compositions and processing techniques that can reduce production costs and environmental impact. These efforts are part of the company’s broader commitment to sustainability and innovation, ensuring that Arlon remains a leader in the development of advanced electronic materials.

Advanced Thermal Management Solutions

Advancements in thermal management solutions are another area of focus for Arlon. The company’s research in thermally conductive materials aims to improve heat dissipation and thermal stability. Innovations in thermal management include enhanced thermal conductivity, improved mechanical properties, and better compatibility with various electronic components. These developments address the increasing thermal challenges faced by modern electronic devices and systems, ensuring reliable operation under high-power conditions. Arlon’s commitment to advancing thermal management technologies helps address the complex thermal requirements of contemporary electronics.

Arlon is also exploring the integration of their thermal management solutions with other advanced materials, such as those used in 5G technology and high-performance computing. These integrations are designed to provide comprehensive solutions that address multiple challenges in electronic design, from signal integrity to thermal management. By staying at the forefront of these technological advancements, Arlon is helping to shape the future of electronics and pave the way for new innovations.

Sustainability and Environmental Impact

Arlon is also focused on the sustainability of their materials. The company is actively researching eco-friendly alternatives and more efficient manufacturing processes to reduce the environmental impact of their products. This includes exploring materials with lower environmental footprints, such as those derived from renewable sources or those that can be recycled more easily. Additionally, Arlon is working to reduce the energy consumption and waste associated with their manufacturing processes, further contributing to their sustainability goals.

Arlon’s commitment to sustainability is reflected in their ongoing efforts to reduce the environmental impact of their materials while maintaining high performance. This focus on sustainability is increasingly important as the electronics industry seeks to balance the demands of technological advancement with the need to protect the environment. By prioritizing sustainability in their research and development efforts, Arlon is not only addressing the needs of today’s electronics industry but also helping to ensure a more sustainable future for generations to come.

Conclusion

Arlon Electronic Materials is a key player in the electronics industry, offering high-performance materials that are essential for the fabrication of PCBs. Their product portfolio, which includes high-frequency laminates, advanced dielectric materials, and thermally conductive materials, addresses the diverse needs of various sectors, including consumer electronics, aerospace and defense, automotive, and industrial applications. Arlon’s commitment to innovation and technological advancement ensures that their materials meet the ever-evolving demands of modern electronics.

As the electronics industry continues to grow and evolve, the need for advanced materials that can support new technologies and address emerging challenges will only increase. Arlon is well-positioned to meet these needs, with a strong focus on research and development, sustainability, and customer collaboration. By providing high-performance materials that drive innovation and improve the performance of electronic systems, Arlon is helping to shape the future of electronics and contributing to the ongoing advancement of technology.

In conclusion, Arlon Electronic Materials is not just a supplier of materials but a partner in innovation, working closely with customers to develop solutions that address the unique challenges of modern electronics. With their extensive product portfolio, commitment to quality, and focus on technological advancement, Arlon is a key player in the electronics industry and a trusted partner for companies looking to push the boundaries of what is possible in electronic design and manufacturing.