Aluminum PCB is product in which circuit graphics are transferred to an aluminum substrate by printing technology. This type of PCB plate has properties such as high thermal conductivity, high electrical conductivity, low weight, and high strength, making it widely used in a variety of fields.

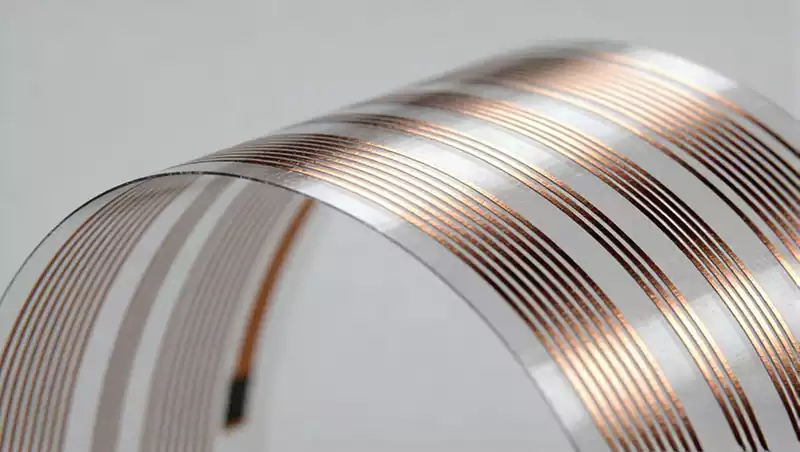

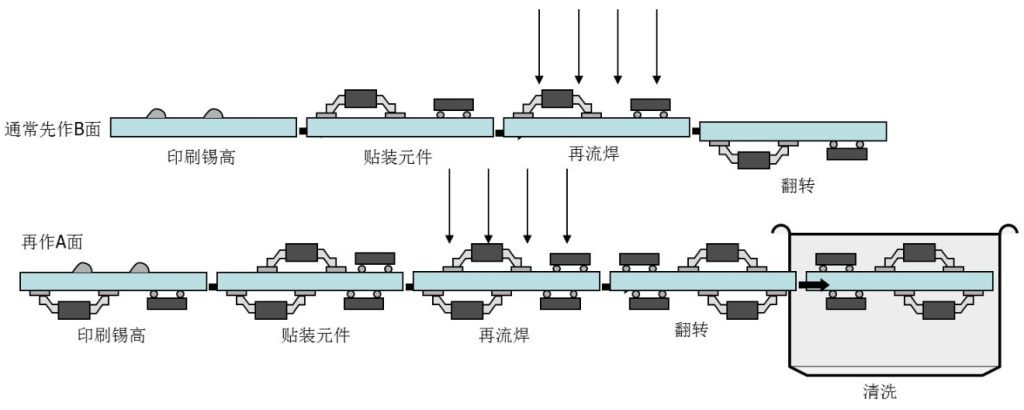

The structure of aluminum PCB usually consists of three layers, which are the circuit layer (copper foil), the insulation layer, and the metal base layer. In high-end applications, it is also designed as a double-sided board with a structure of circuit layer, insulation layer, aluminum base, insulation layer, and circuit layer. In very few applications, there may also be multilayer boards, consisting of a regular multilayer board laminated with an insulating layer and an aluminum base.

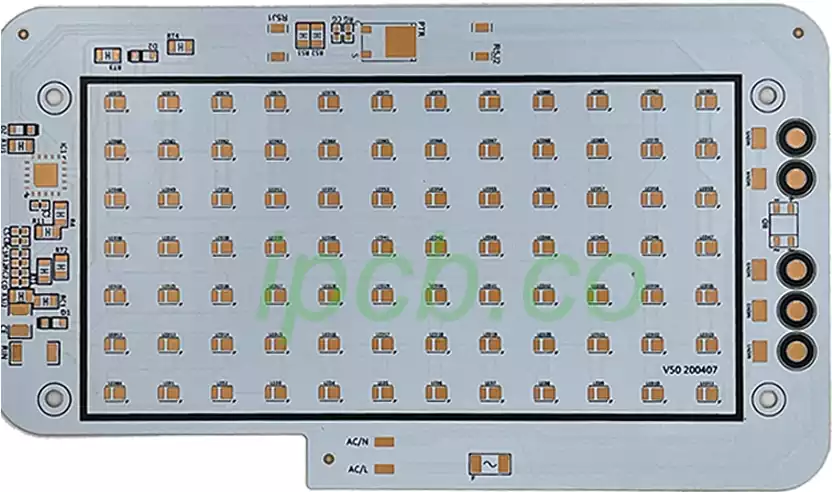

Aluminum PCB can dissipate heat from electronics, so they are often used in applications that require tight tolerances and high power. For example, they are used in a wide range of applications such as communication equipment, computer hardware, industrial controls, and automotive electronics. Due to their good thermal properties, aluminum substrate is particularly popular in electronic devices that require efficient heat dissipation.

In addition, aluminum printed circuit boards are also highly sustainable and environmentally friendly, as they can be recycled, helping to reduce resource consumption and environmental pollution.

For the production of aluminum printed circuit boards, the material requirements are very strict. Substrate materials must have good electrical properties, mechanical strength, and thermal stability to ensure stable circuit operation. The choice of conductive materials is also very critical, copper foil is widely used because of its good conductivity and solderability. In addition, the cover layer material needs to have the characteristics of high temperature and corrosion resistance to ensure the safety of the circuit.

Advantages of aluminum PCB:

High Thermal Conductivity: Aluminum printed circuit boards can transfer and handle heat quickly, which is critical for electronic devices that require high thermal performance.

High conductivity: Aluminum printed circuit boards are highly conductive and provide stable and efficient electrical connections.

Lightweight: Compared to traditional printed circuit boards, aluminum printed circuit boards have a lighter weight, which helps to reduce the overall weight of the equipment, especially in the aerospace and automotive industries with significant advantages.

High strength: Aluminum printed circuit boards have high mechanical strength and durability, and can withstand the mechanical stress of various environmental conditions to ensure the stability and reliability of the board.

Environmental protection: aluminum printed circuit boards are easy to recycle, helping to reduce environmental pollution and resource consumption.

Economical: Aluminum is abundant on the earth, with relatively low mining and refining costs, making the production of aluminum printed circuit boards relatively inexpensive.

Highly customizable: Aluminum printed circuit boards can be customized according to specific needs, including the design of circuit graphics, the thickness of the aluminum substrate, and the thickness of the insulation layer to meet the needs of different application scenarios.

High reliability: Aluminum printed circuit boards have high reliability and stability, which can ensure the normal operation of electronic equipment for a long time.

In short, the characteristics of aluminum plate make them widely used in communication equipment, computer hardware, industrial control, automotive electronics, and other fields.

Disadvantages of aluminum PCB:

Higher cost: compared with traditional fiberglass circuit boards, aluminum printed circuit boards are more expensive to manufacture, which may increase the overall cost of electronic devices.

Higher production difficulty: the manufacturing of aluminum printed circuit boards requires high-precision processes and technologies, which have higher requirements for equipment and processes.

Difficulty of machining: The hardness of aluminum substrates is large, and the difficulty and cost of machining is relatively high.

Limitations of recycling: Although aluminum printed circuit boards are easy to recycle, the difficulty and cost of recycling may increase due to their complex structure and material diversity.

Aluminum substrate has a wide range of application scenarios, mainly including the following aspects:

Communication equipment: in the field of communication equipment, it is widely used in base stations, switches, routers and other equipment. Due to its high thermal conductivity and high electrical conductivity, it can provide high-speed and stable signal transmission to ensure the normal operation of communication equipment.

Computer hardware: In the field of computer hardware, it is a key component of hardware such as motherboards, graphics cards, sound cards, network cards and so on. It provides a stable electrical connection and mechanical support for the computer system, guaranteeing the performance and reliability of the computer system.

Industrial control: In the field of industrial control, it is widely used in automation equipment, instrumentation, motor controllers and other equipment. It can provide reliable electrical connections and mechanical support, which promotes the intelligence and efficiency of industrial production.

Automotive electronics: In the field of automotive electronics, it is widely used in engine control modules, body control modules, entertainment systems and other automotive electronic equipment. Due to its lightweight and high-strength characteristics, aluminum printed circuit boards enhance the performance and safety of automotive electronic equipment.

In addition to the above fields, it is also widely used in aerospace, medical devices, smart home, and other fields. For example, in the field of aerospace, it is used to manufacture control systems for airplanes and satellites; in the field of medical devices, it is used to manufacture control systems for medical equipment and instruments; and in the field of smart home, it is used to manufacture control systems for smart home equipment and automation systems.

As a key electronic component, the technological progress and industrial innovation of aluminum pcb is driving the rapid development of various industries. With its unique performance advantages, wide range of applications, and prospects for sustainable development, the aluminum substrate will continue to play an important role and make significant contributions to the future development of science and technology.