Why do we need Custom PCB?

The process of PCB design requires professional electronic engineers to design it, and then PCB layout engineers layout the circuit. Almost every PCB used in a product is designed separately for it. In addition to the public PCB design plans announced by chip companies, some manufacturers have made modifications to the public PCB design plans to become their own unique products.

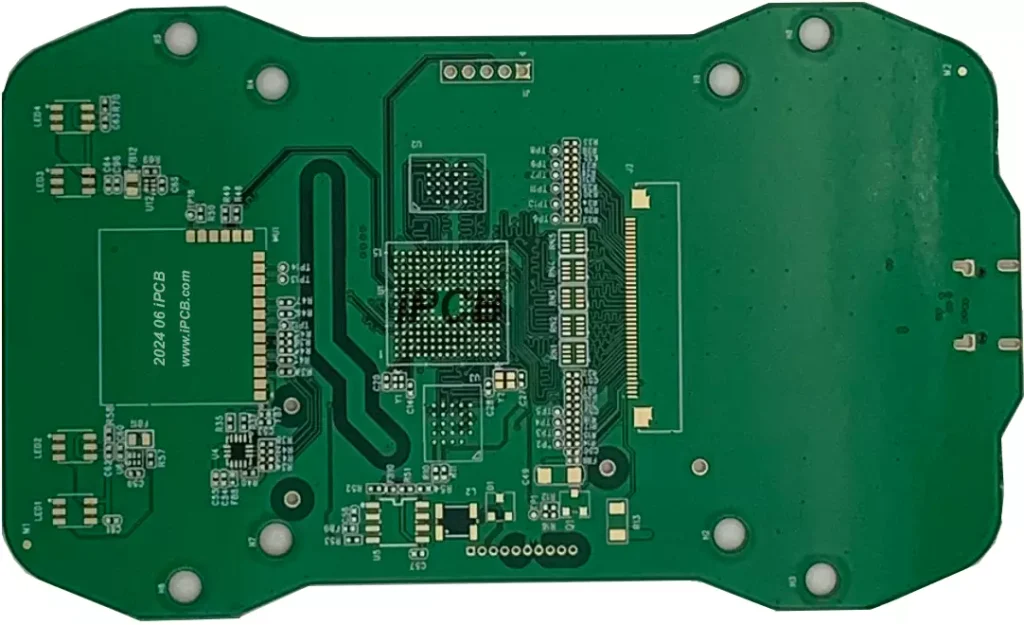

iPCB is a manufacturer specializing in Custom PCB. As a leading enterprise in the industry, iPCB is committed to providing high-quality, reliable, and innovative PCB to meet the constantly changing and growing needs of customers.

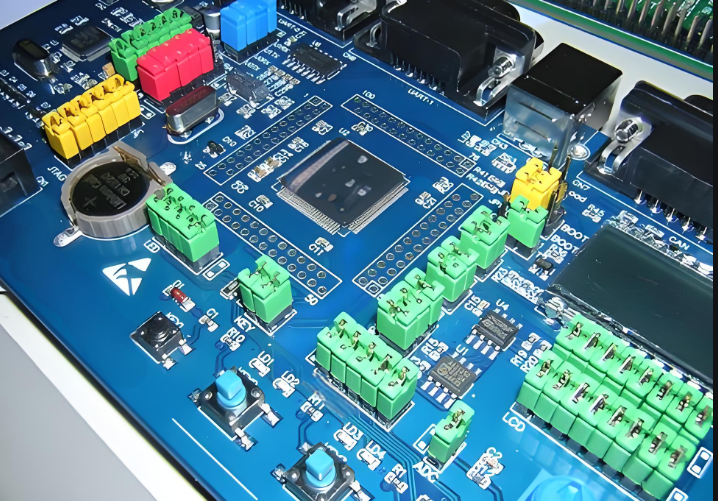

With the development of information technology and the acceleration of product updates, the application of PCB in various fields is becoming increasingly widespread. Whether it is computers, communication equipment, automotive electronics, medical equipment, or household appliances, PCB play a crucial role. iPCB has a competitive advantage in this rapidly developing industry by continuously innovating and optimizing products to meet the needs of the market and customers.

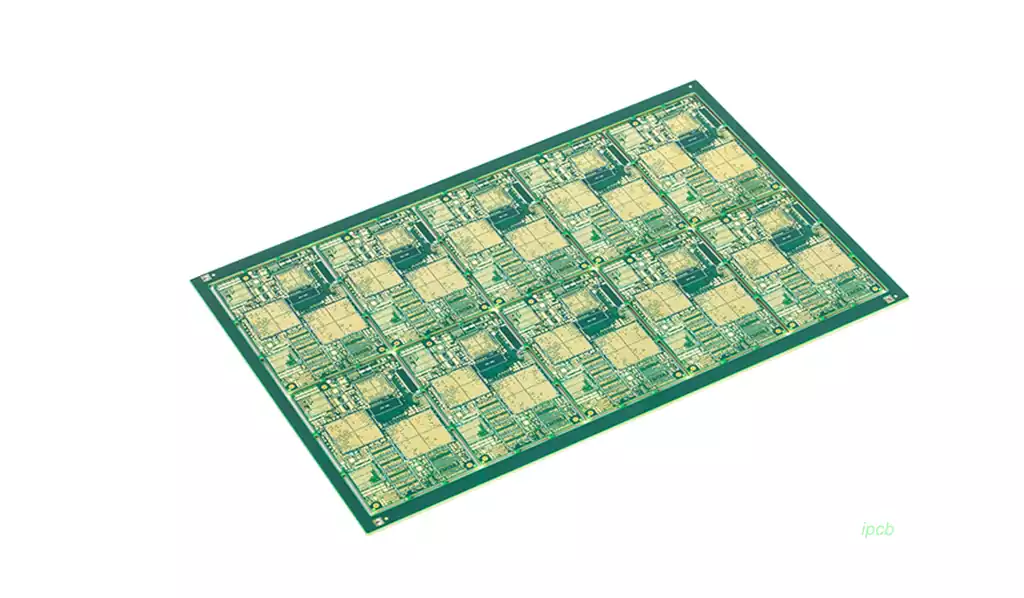

In the early days of its establishment, iPCB mainly focused on producing double-sided and multi-layer circuit boards. With excellent quality and excellent customer service, iPCB has gradually gained a reputation in the market and rapidly expanded the company’s scale and production capacity.

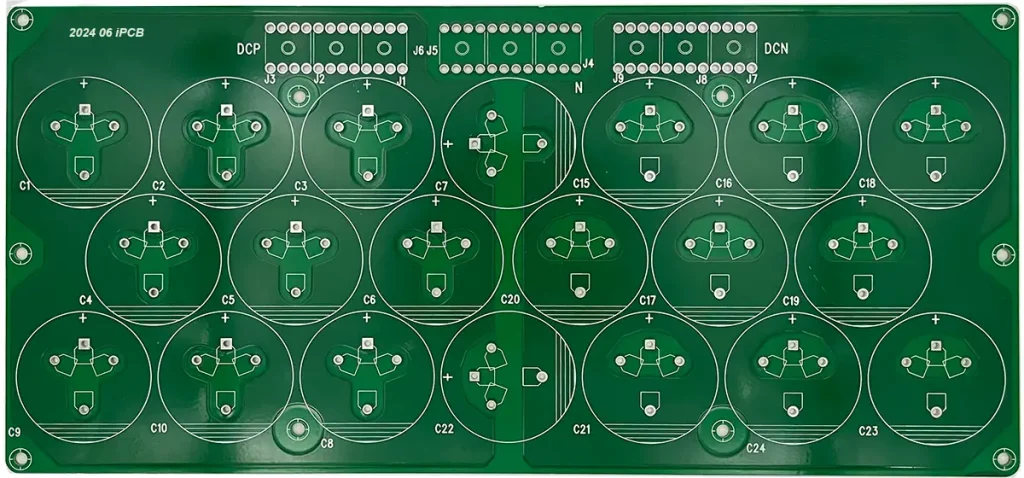

With the development of technology and changes in the market, iPCB constantly pursues innovation and expands its product line. At present, iPCB mainly customizes various types of circuit board solutions such as multi-layer PCB, high-density printed circuit boards, rigid circuit boards, flexible circuit boards, and rigid flexible combination circuit boards. Whether in consumer electronics, communication equipment, industrial control, medical instruments, or other fields, iPCB products have been widely used and praised.

The future development goal of iPCB is to continuously expand its business scale, improve product quality and technological innovation capabilities, and continue to provide reliable Custom PCB to global customers. At the same time, iPCB will continue to strive to protect the environment, promote employee development and sustainable social development, and make its own contribution to building a harmonious society.

Custom PCB requires gerber files and production requirements. Please send the files to the email of iPCB, and our marketing personnel will reply to your quotation soon. Email: sales@ipcb.com

What affects the price of customized PCB?

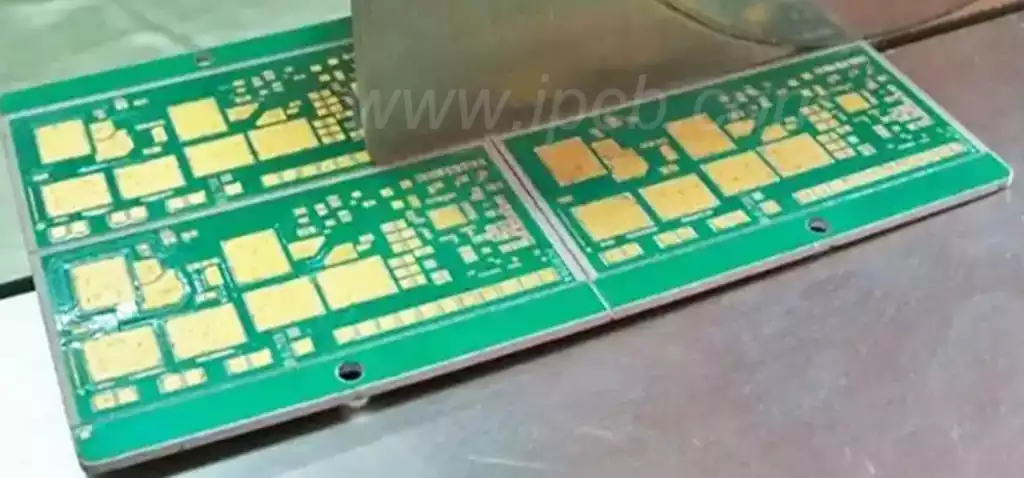

Raw material cost: Raw materials are the foundation of Custom PCB, and the cost of different types of raw materials varies, which also affects the final manufacturing cost. For example, there is a significant price difference between FR4 and CEM-1.

Production scale: Large scale production can reduce the cost of Custom PCB, while small-scale production can result in relatively higher costs. This is because mass production can disperse fixed costs and improve production efficiency.

Manufacturing complexity: The higher the complexity of PCB, the more complex the production process required, resulting in increased costs. For example, special processes such as multi-layer PCB boards, blind holes, and buried holes can make the production process more complex, thereby increasing costs.

Quality requirements: The higher the quality requirements, the stricter the quality control and testing aspects of the Custom PCB production process, resulting in increased costs. For example, the higher the requirements for surface treatment, impedance control, reliability testing, etc., the higher the cost.

Delivery time: The tighter the delivery time, the more frequent the urgent processing and priority production in the Custom PCB production process, which will lead to increased costs.

Customization level: The higher the customization level, the stricter the special requirements in the customization processing and production process, resulting in increased costs. For example, the higher the requirements for custom shapes, interfaces, wiring, component layouts, etc., the higher the cost.

Labor costs: There are differences in labor costs among different regions and enterprises of different sizes. Generally speaking, labor costs are higher in developed regions, and lower productivity in small businesses can also affect labor costs.

Other factors: Other factors that affect costs include the input and selection of production equipment, production environment, and production processes. For example, high-precision mechanical equipment and advanced production processes can improve product quality and production efficiency, thereby reducing the cost per unit product.

What are the advantages of iPCB Custom PCB?

Good craftsmanship: iPCB has excellent electronic craftsmanship, which not only provides the production level of high-quality PCB, but also meets the needs of customers for different products, ensuring the long-lasting stability of circuit boards.

Experienced: iPCB is a custom PCB manufacturer with extensive experience, and the quality of the circuit boards produced has been recognized by a large number of customers.

Fast delivery speed: iPCB can complete the delivery of small and medium-sized custom PCBs in a short period of time, with fast delivery time and the ability to meet customer requirements within the specified time.

Good service quality: iPCB requires customer service personnel to respond promptly and carefully to customer issues, and provide engineering and technical support.

Strong technical strength: Technical strength mainly depends on whether it has advanced automated production equipment. iPCB has strong hardware and is equipped with a professional production management team, which can effectively ensure the quality of Custom PCB,

Good product quality: Good Custom PCB manufacturers have obtained some quality system certifications. If they have such qualifications, it indicates that they have strong professional strength and rich industry experience.

PCBA one-stop service: PCBA one-stop service refers to customers submitting all materials to the factory, and the factory directly assembles the finished products and sends them to customers. Customers only need to conduct testing.

Raw material guarantee: using fr-4 A-grade materials, with a complete range of high-frequency PCB materials and high-speed PCB materials, to ensure the reliable quality of customer custom PCB.

Price Guarantee: Using a brand new Custom PCB pricing system and integrating with an ERP system that supports online pricing, price calculation is transparent, providing customers with price guarantee.

Do you want to learn more about iPCB? Come to iPCB! After more than a decade of development, iPCB has now developed into a one-stop manufacturer for PCB custom and PCBA customization. Our services include custom PCB, sample assembly, electronic manufacturing, SMT manufacturing, PCBA assembly, Box Build Assembly, and component procurement.