The widespread application of electronic products has made electronic solution design an important part of modern technology. Electronic solution design refers to a set of solutions composed of electronic components, circuits, sensors, etc., used to achieve specific functions or meet specific needs.

The basic principle of electronic scheme design is to select suitable electronic components based on specific needs and goals, and combine them into circuits to achieve specific functions. Before design, it is necessary to analyze the requirements and determine the required electronic components and other materials.

The process of electronic scheme design can be roughly divided into the following steps:

Electronic solution design process ->Requirements analysis ->Electronic component selection ->Circuit design ->PCB design ->Prototyping ->Testing and verification ->Optimization and improvement ->Mass production and quality control

Requirement analysis: Requirement analysis is the first crucial step in electronic solution design. At this stage, designers need to communicate with clients or users to understand specific requirements and requirements. Through communication with customers, determine the functions, characteristics, performance, etc. of electronic solutions.

Electronic component selection: Based on the results of the requirements analysis, designers need to select appropriate electronic components. The selection of electronic components needs to consider factors such as performance, quality, and price. Common electronic components include chips (such as microcontrollers, logic gates, etc.), capacitors, resistors, inductors, etc.

Circuit design: In electronic scheme design, circuit design is a crucial step. Circuit design includes steps such as determining the circuit topology, drawing circuit schematics, and conducting circuit simulations. Through circuit design, the connection relationship between electronic components can be clarified to ensure the normal operation of the circuit.

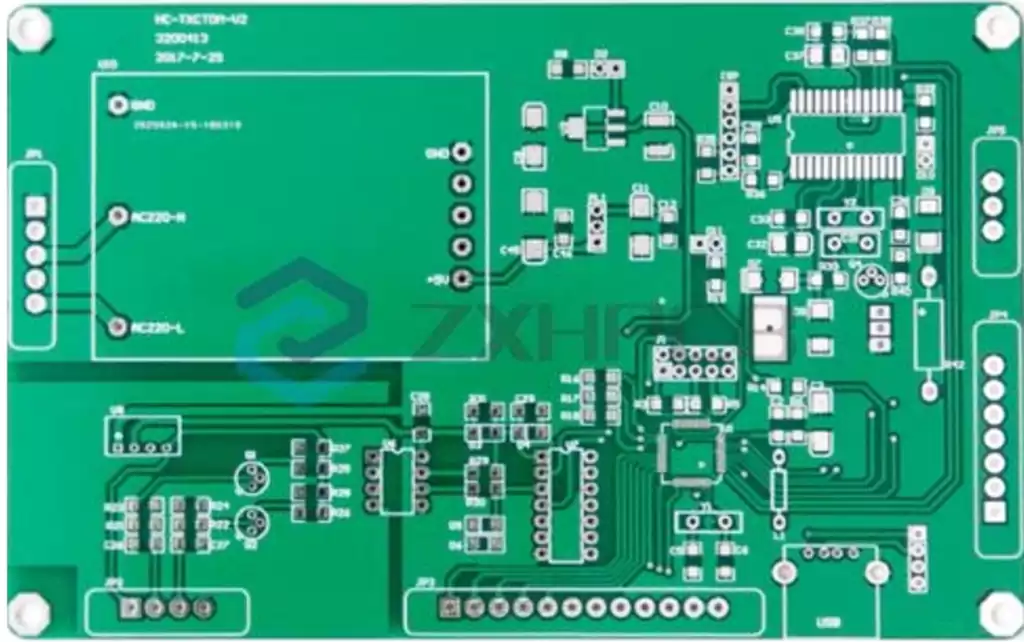

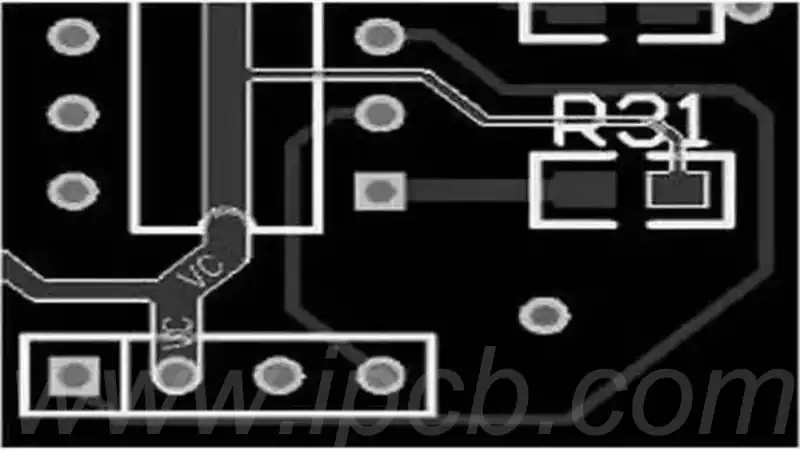

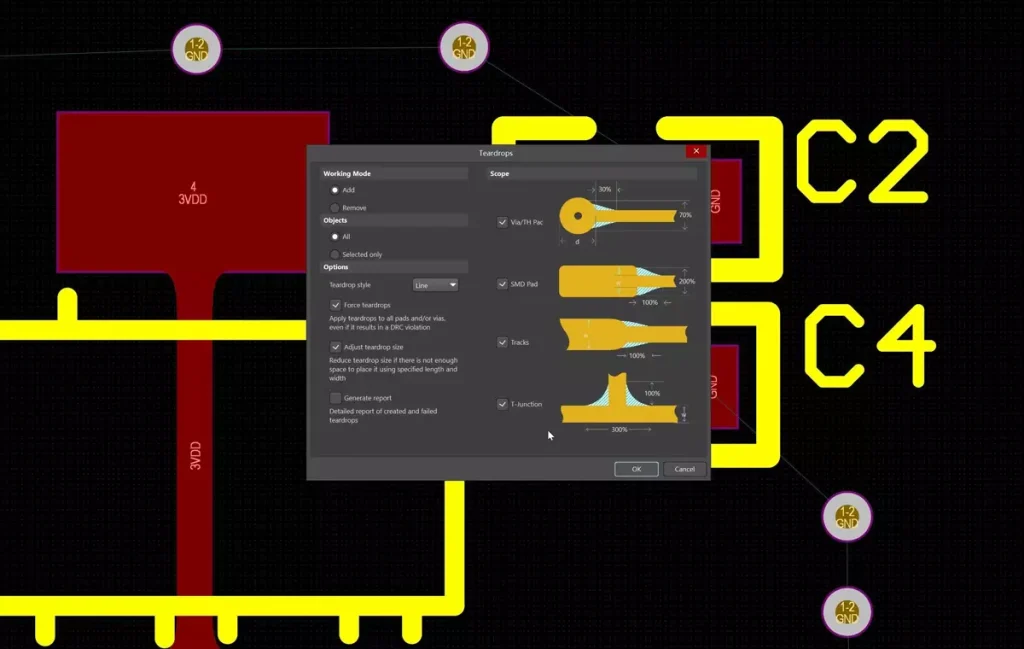

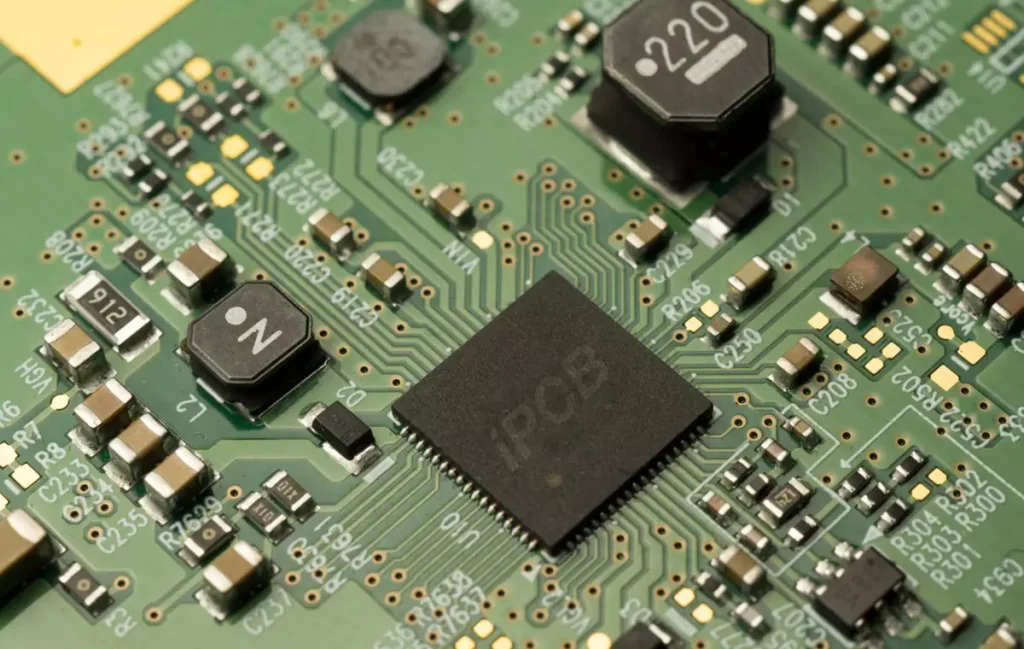

PCB design: PCB design refers to the process of converting circuit designs into actual manufacturable printed circuit boards (PCBs). In PCB design, designers need to consider factors such as wiring, component layout, and hierarchical design to ensure the stability and reliability of the circuit.

Prototyping: After completing the PCB design, the feasibility and performance of the electronic solution can be verified through prototyping. Prototype production can be completed through steps such as processing, welding, and testing.

Testing and Verification: After completing the prototype production, it is necessary to test and verify the electronic solution. Testing can be conducted through instruments and equipment to ensure that the performance and stability of electronic solutions meet design requirements.

Optimization and improvement: Based on the results of testing and validation, designers can optimize and improve. The selection of electronic components can be adjusted, and the circuit design can be modified to improve the performance and functionality of electronic solutions.

Mass production and quality control: Carry out mass production of products and implement quality control measures to ensure that each product meets specifications and standards.

Electronic solution design generally adopts a top-level design approach based on the design tasks, functions, and performance requirements of the product. It analyzes the functions that the product should complete, decomposes the overall function into several sub functional modules, clarifies the relationship between primary and secondary functions, and forms an overall plan. Through comparative argumentation, modification, and optimization, a relatively complete optimal solution is formed, while proposing requirements related to structure, reliability, standardization, quality control and supervision, metrological control, process, and other aspects.

Electronic solution design is an important means to achieve specific functions or meet specific needs. By analyzing the requirements and selecting appropriate electronic components, a powerful, stable, and reliable electronic solution can be designed. In practical applications, electronic scheme design can be applied in various fields, bringing convenience and benefits to people’s lives and work.

To assist small and medium-sized enterprises in reducing labor costs and shortening product development cycles, iPCB has specially formed its own R&D team to provide customers with one-stop product development and module module product solutions.

The iPCB service covers a full process, one-stop product solution design service, which integrates solution design, research and development selection, material matching, and production and manufacturing. IPCB has accumulated over 100 cases covering multiple fields, including network communication, Internet of Things, sensors, robotics, industrial control, automotive electronics, and more. The R&D team has rich practical experience and can provide technical support and best practices to customers.

In the complex process of electronic product solution design, iPCB not only provides a one-stop solution for the entire process, but also provides key technical support and professional guidance to customers, helping them successfully transform concepts into innovative physical products, and helping them create high-quality and reliable electronic products in the fiercely competitive electronic market.