Electronic Manufacturing Services (EMS), also known as ECM (Electronic Contract Manufacturing), is an electronic manufacturer that provides a range of services for electronic product brand owners, including manufacturing, procurement, partial design, and logistics.

Compared to traditional OEM or ODM services that only provide product design and OEM production, electronic manufacturers provide knowledge and management services such as material management, logistics transportation, and even product maintenance services.

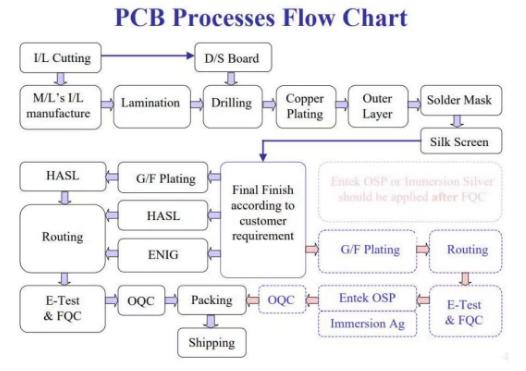

The electronic manufacturing production process involves many processes and links. Electronic manufacturing services are a comprehensive service that includes product development, production, procurement, quality management, and transportation logistics. Generally speaking, electronic manufacturing services include the above content. In the beginning, we mainly helped customers with the processing part, so we only managed the production part, which is OEM (original equipment manufacturing). Later, it developed to the point where we could assist some clients in developing and designing products, which was called ODM (Original Design Manufacturer). In other words, compared to OEM, ODM has added new elements. At present, electronic manufacturing service providers have done what ODM and OEM do.

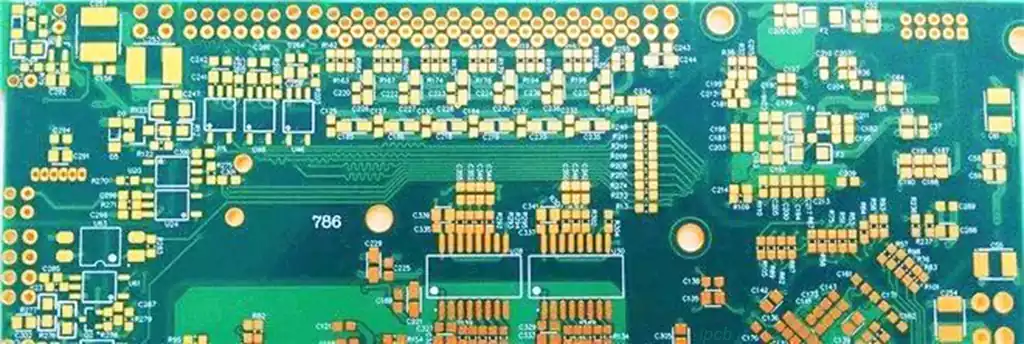

We have complete electronic manufacturing service equipment: surface mount equipment, welding equipment, wire harness assembly equipment, network assembly equipment, 3D printing and additive manufacturing equipment, cleaning equipment, etc.

Continuous evolution and innovation are driving the development of electronic manufacturing services toward intelligence, miniaturization, sustainability, and multi-process integration. This will not only promote the advancement of electronic manufacturing technology but also provide more innovative and flexible solutions for constantly changing market demands.

a. Intelligence and automation. With the advancement of artificial intelligence, machine learning, and robotics technology, electronic assembly equipment is moving towards greater intelligence and automation. Automated mounting and welding machines can automatically adjust according to product requirements, reduce manual operations, and improve production efficiency and consistency. Intelligent vision systems can be used for real-time detection and correction of defects during the installation process, thereby reducing manual inspection work. By integrating data analysis and predictive maintenance, equipment can predict faults and perform maintenance, reducing downtime.

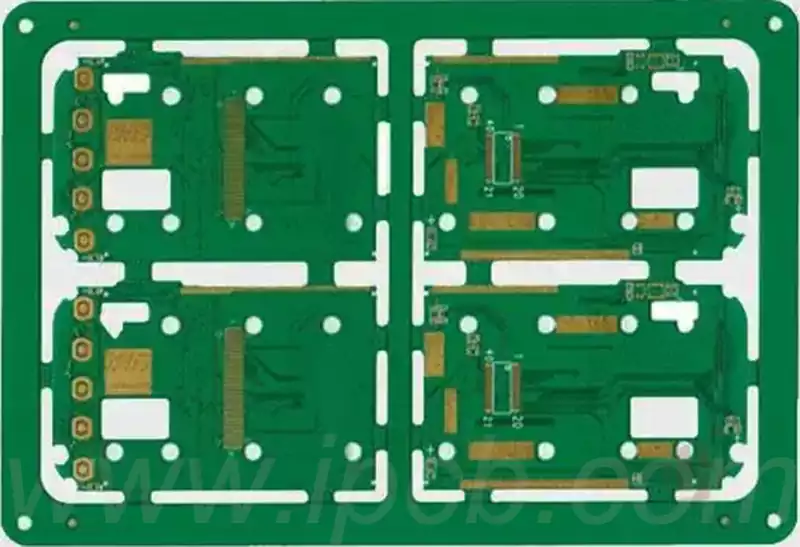

b. Microminiaturization and high-density integration. With the rapid miniaturization and multifunctionality of electronic devices, electronic assembly devices are adapting to smaller and higher-density components and circuit boards. This requires more precise mounting and welding techniques, as well as finer material and process control. The new type of micro mounting and welding machines can achieve a high-density layout of components in a very small space, meeting the increasingly miniaturized needs of electronic products.

c. Sustainability and green electronic manufacturing. Against the backdrop of increasing environmental awareness, the electronic assembly equipment industry is moving towards a more sustainable direction. Manufacturers are focusing on reducing energy consumption, waste generation, and the use of harmful substances. The development of new materials and the adoption of green manufacturing processes can help reduce their impact on the environment. At the same time, the treatment and recycling of electronic waste have also become a focus of industry attention, and some equipment manufacturers are studying how to reduce waste generation in the electronic assembly process.

As an electronic manufacturer, iPCB continues to strengthen its research and development in technology to meet the growing market demand and improve its technological level, in order to enhance quality and productivity. iPCB has now entered the production and manufacturing process of high-end electronic manufacturing, and has established long-term and stable partnerships with many world-renowned enterprises.