Introduction and Definition of Soldering Wire

In modern electronics manufacturing, metalworking, and various electrical assembly processes, soldering is a crucial process for connecting components and conductors. Among the many soldering materials, soldering wire is one of the most common and essential soldering consumables due to its ease of use, wide applicability, and consistent soldering results. It is not only widely used in professional industrial production lines but is also a near-essential item in the DIY workbench of electronics enthusiasts and the daily toolbox of maintenance engineers.

What is Soldering Wire?

Soldering wire is a wire-like material specifically used for soldering. After heating and melting, it securely connects metal surfaces or electronic component pads together, providing electrical conductivity, mechanical fastening, and protection. It is typically made of alloy metals and may contain flux to remove surface oxides, improve wettability, and enhance solder joint quality.

Different applications require different soldering wire requirements:

In electronic circuit board soldering, solder wire is required to have excellent conductivity and a low melting point to prevent damage to components caused by high temperatures. In the field of metal processing and repair, soldering strength, corrosion resistance, and mechanical stability may be more important.

The Status and Application Background of Soldering Wire

The history of soldering wire can be traced back to the late 19th century, when electronic products began to enter industrial production. With the development of electronic technology, especially the rise of electronic devices such as televisions, radios, and computers in the mid-20th century, solder wire gradually became a standard material for mass production. Today, it is indispensable for everything from high-end aerospace and automotive electronics to consumer mobile phones and laptops, as well as ordinary household appliances and LED lighting.

Globally, soldering wire is not only regarded as a welding material but also a vital component of the electronics manufacturing industry chain. With the continuous upgrading of environmental regulations (such as the RoHS Directive), its materials and production processes are also evolving, gradually shifting from traditional lead-containing solder wire to environmentally friendly lead-free solder wire.

The Core Functions of Soldering Wire

In the soldering process, soldering wire’s main functions are as follows:

Connection: The molten solder firmly bonds two or more metal surfaces.

Conductivity: Providing a stable electrical path in electronic circuits, ensuring the proper transmission of signals or current. Protection: Effectively isolates air and moisture, preventing oxidation and corrosion at the soldered parts.

Stress Buffering: Absorbs a certain degree of thermal expansion and contraction, or mechanical stress, extending the life of the soldered parts.

Why Learn More About Soldering Wire?

For technicians, a thorough understanding of the characteristics of different types of solder wire can help improve soldering quality and production efficiency. For procurement personnel, understanding the classification, materials, and application scenarios of solder wire can help select the most cost-effective and environmentally friendly products. For newcomers to the industry, understanding the basics of solder wire is an important first step in entering the electronics manufacturing field.

This article will provide a systematic and comprehensive analysis of soldering wire from the perspectives of type classification, material composition, selection criteria, usage and storage methods, common problems, and safety regulations, to help readers make more informed decisions in their work.

Main Types and Classification Standards of Soldering Wire

Before selecting or using soldering wire, it is important to first understand its classification and characteristics. Different types are suitable for different applications. Improper selection can not only affect soldering quality but can also damage components, reduce production efficiency, and even pose safety hazards. Generally speaking, soldering wire can be categorized based on multiple factors, including alloy composition, flux content, flux type, and diameter specifications.

Classification by Alloy Composition

The alloy composition of soldering wire is a key factor in determining its melting point, mechanical properties, wettability, and conductivity. Common classifications include:

Lead-Containing Solder Wire (Sn-Pb)

Composition Ratio: The traditional ratio is 63% tin (Sn) + 37% lead (Pb), known as 63/37 eutectic solder, with a fixed melting point of 183°C.

Advantages: Low melting point, good fluidity, excellent wettability, bright solder joints, and minimal cooling shrinkage.

Disadvantages: Lead is toxic, and its use and disposal must strictly comply with environmental regulations.

Applications: Still used in some military, maintenance, and non-export industrial equipment.

Lead-Free Solder Wire

Common ratios: Sn-Cu (tin-copper), Sn-Ag-Cu (ternary alloy), Sn-Ag, etc. Advantages: Compliant with environmental standards such as RoHS, making it more user-friendly and environmentally friendly.

Disadvantages: High melting point (generally between 217°C and 227°C), requiring higher heating equipment requirements and stricter soldering speed and process control.

Applications: Widely used in export electronics, consumer electronics, automotive electronics, and other fields.

Special Alloy Solder Wire

Low-temperature solder wire: For example, Sn-Bi (tin-bismuth) alloys have melting points as low as 138°C, making them suitable for temperature-sensitive components.

High-strength solder wire: Incorporating elements such as Ni and Ge enhances mechanical strength and corrosion resistance, making it suitable for connections in harsh environments.

Classification by Flux Content

Flux is used to remove oxide layers from metal surfaces, improve wettability, and reduce cold joints and fins. Whether the solder wire is pre-filled with flux directly affects the ease of soldering.

Flux-Cored Solder Wire

Pre-filled with flux, eliminating the need for additional additions. Common flux forms include rosin-based, synthetic resin-based, or water-soluble. Advantages: Simple operation and high efficiency, particularly suitable for manual soldering and small-batch production.

Solid Solder Wire

Solid Solder Wire contains no internal flux and requires an external flux during soldering. It is often used in automated soldering equipment or specialized process scenarios, allowing for greater flexibility in selecting the type of flux.

Classification by Flux Type

Even for cored solder wire, different flux types can significantly affect soldering properties:

Rosin-Based: Based on natural rosin, it offers excellent insulation and wettability, making it suitable for electronic circuits.

Activated Rosin-Based (RA/RMA): Contains an activator that quickly removes oxides and is suitable for difficult-to-solder metal surfaces, but requires careful post-solder cleaning.

Water-Soluble Flux: Post-solder residue can be cleaned with water, making it environmentally friendly and process-friendly. However, moisture-induced corrosion must be avoided.

No-Clean flux: Leaves minimal post-soldering residue and offers high electrical insulation performance, making it suitable for applications where cleaning is difficult.

Classification by Diameter

The diameter of soldering wire directly impacts solder volume control and solder joint quality:

Fine diameter (0.3mm-0.6mm): Suitable for precision soldering, such as on mobile phone motherboards and micro-sensors.

Medium diameter (0.8mm-1.2mm): Suitable for most general electronic assembly work.

Coarse diameter (1.5mm and above): Suitable for soldering larger pads, terminals, and metal components.

On automated production lines, solder wire with a fixed diameter is typically selected based on product structure and solder joint size to ensure solder joint consistency and efficiency.

Comprehensive Classification Application Example

In actual procurement and production, classification is often a comprehensive consideration. For example:

A production line for exporting smart home devices might select lead-free, rosin-cored, 0.8mm diameter soldering wire. A repair engineer repairing an older radio might choose a lead-containing, activated rosin core, 0.6mm diameter type to improve soldering feel and wettability.

Main Components and Types of Solder Wire

The performance and applicability of solder wire depend largely on its chemical composition and structural design. Understanding the composition and classification of different types of solder wire is crucial for technicians to select the appropriate product and improve soldering quality.

Classification by Alloy Composition

Lead-Containing Solder Wire

Lead-containing solder wire consists of tin (Sn) and lead (Pb), with the most common ratios being 63/37 (63% Sn, 37% Pb) and 60/40. This type of solder wire has a low melting point (183°C or slightly higher), excellent wettability, and stable soldering, making it widely used in traditional electronics manufacturing. However, due to the toxicity of lead, its use has been restricted in many regions.

Lead-Free Solder Wire

Lead-free solder wire typically uses formulas such as tin-copper (Sn-Cu), tin-silver-copper (Sn-Ag-Cu, SAC), and tin-silver (Sn-Ag). While it has a higher melting point (typically above 217°C), it is environmentally friendly and complies with environmental regulations such as RoHS and REACH, making it a mainstream trend.

Special Alloy Solder Wire

To meet specific industrial needs, special solder wires containing elements such as bismuth (Bi), zinc (Zn), and indium (In) are also available. These special ingredients can lower the melting point, increase solder joint strength, or improve reliability under high/low temperature conditions.

Classification by Flux Core Type

Solder wire typically contains a flux core to help remove oxides from the metal surface and improve wettability during soldering.

Rosin Core: Suitable for the electronics industry, it offers excellent electrical insulation and produces minimal residue. Water-soluble core: Residue is easily cleaned with water, making it suitable for applications requiring high cleanliness. However, uncleaned cores can corrode metals.

No-clean core: Residue is minimal and stable, making it suitable for mass production and reducing cleaning steps.

Classification by solder wire structure:

Single-core solder wire: Consists of a single flux core, offering a simple structure and low cost.

Multi-core solder wire: Contains multiple flux cores, resulting in more even flux distribution and more stable soldering performance.

Performance Differences and Selection Key Points:

Solder wires with different compositions, flux core types, and structures vary significantly in melting point, wetting speed, solder joint brightness, and residue properties.

For general electronics manufacturing, lead-free SAC305 (Sn96.5/Ag3.0/Cu0.5) no-clean multi-core solder wire is often used.

For repair or manual soldering, 63/37 lead-containing rosin core solder wire with a lower melting point can be selected to improve soldering efficiency. For high-reliability military and aerospace applications, high-silver content solder wire can be selected to enhance solder joint strength.

Solder Wire Production Process and Quality Control

The manufacturing of solder wire involves more than simply melting the metal and drawing it into thin wires. It involves multiple critical steps, including alloy proportioning, flux filling, wire drawing, and surface treatment. Oversight in any of these steps can lead to poor soldering performance, weak solder joints, or even solder defects. Therefore, a thorough understanding of the production process and quality control helps us assess product quality and optimize procurement decisions.

Alloy Melting and Refining

Raw Material Selection

High-quality solder wire requires high-purity tin ingots (Sn) and other metal raw materials (Ag, Cu, Pb, etc.), and their impurity content must be strictly controlled. For example, lead content is crucial to the environmental performance of lead-free solder wire and must meet RoHS limits (<0.1%).

Alloy Melting: The raw materials are melted in a high-temperature furnace according to the desired proportions and thoroughly stirred to ensure a uniform distribution of alloying elements. Refining and Impurity Removal: Inclusions and gases are removed by adding a slag remover, using vacuum refining, or using an inert gas shield, ensuring good wettability and a porosity-free solder joint during welding.

Flux Preparation and Filling

Flux Preparation

The chemical composition of the flux directly affects the soldering performance and residue characteristics of the solder wire. High-quality flux must balance deoxidation, wettability, insulation, and residue stability.

Filling Method

While the solder wire is being formed, specialized equipment is used to precisely fill the flux into the center of the wire to ensure uniform distribution. Intermittent or unevenly distributed flux cores can lead to problems such as cold solder joints and darkened solder joints during welding.

Wire Drawing

During initial and final drawing, the alloy billet passes through multiple drawing dies, gradually reducing its diameter to ensure accurate outer diameter and stable flux core position. Tension control is used to maintain a stable tension during the drawing process to prevent core breakage and flux leakage.

Surface Treatment and Winding

Surface polishing removes the surface oxide layer through physical or chemical means, resulting in a bright and easily wettable solder wire surface.

Anti-oxidation coating applies an anti-oxidation treatment (such as a thin organic protective film) to the solder wire surface to extend its shelf life.

Reel packaging: Solder wire is wound into reels of a specified weight (e.g., 500g, 1kg, etc.) according to customer requirements and vacuum-packed or moisture-proof packaging to prevent moisture and oxidation.

Quality Inspection and Control

Chemical composition testing uses an optical emission spectrometer (OES) or X-ray fluorescence spectrometer (XRF) to determine alloy composition to ensure accurate ratios and compliance with environmental standards.

Soldering performance testing includes metrics such as wetting time, solder joint brightness, residue volume, and resistivity to ensure actual soldering performance meets standards.

Appearance and dimensional inspection checks the uniformity of solder wire diameter, surface finish, and flux core continuity.

Common Production Defects and Control Methods:

Intermittent flux core → Avoid core breakage by optimizing the filling process and controlling the soldering tension. Darkening due to surface oxidation → Use inert gas shielding during production and strengthen anti-oxidation packaging.

Alloy composition deviation → Improve raw material weighing accuracy and melting and stirring uniformity.

Application of Solder Wire in Electronics Manufacturing and Repair

Solder wire plays a central role in modern electronics manufacturing and repair. Its applications range from soldering small electronic components to connecting high-power electrical devices, covering nearly all electronic assembly and repair scenarios. Mastering the correct application of solder wire is crucial for improving soldering quality, extending component life, and reducing production costs.

Application of Solder Wire in Electronics Manufacturing

PCB Assembly (Through-Hole and SMD)

In through-hole component soldering, solder wire is heated and melted to fill the gap between the pad and the lead, forming a stable solder joint.

For surface mount components (SMD), solder wire is often used with an automatic soldering machine (wave soldering or reflow soldering). The molten solder precisely wets the pad and component terminals. When selecting solder wire, consider its melting point, diameter, and flux core type to ensure bright, dry, and bridging-free solder joints.

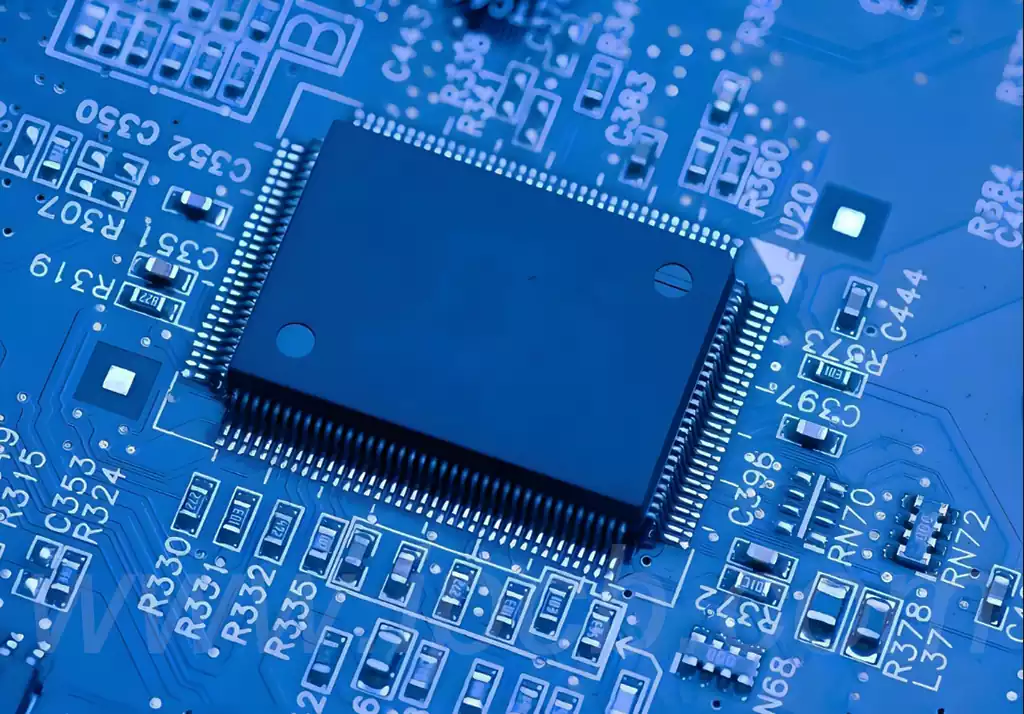

For high-reliability electronic products, such as aerospace, automotive electronics, and medical devices, solder wire must not only meet soldering performance requirements but also ensure vibration resistance, heat resistance, and corrosion resistance. High-silver content solder wire or special alloy solder wire is typically selected, combined with rigorous quality testing and soldering process control to ensure long-term solder joint reliability.

Multilayer PCBs and Precision Circuit Boards

For multilayer boards or fine-pitch packages like BGA and QFP, the solder wire diameter and flux type have a significant impact on soldering performance.Power is crucial.

Solder wire that is too thick can cause short circuits in solder joints, while too thin may not form sufficient solder volume. Therefore, precise selection is required based on pad size and process requirements.

Solder Wire Applications in Electronics Repair

For manual repairs, solder wire is the most commonly used material for manual soldering in mobile phones, computers, and home appliances. Repair engineers must master soldering temperature control, solder volume adjustment, and solder joint cleaning techniques to avoid damaging components or circuit boards.

For component rework and replacement, using the appropriate type of solder wire for disassembly and resoldering of damaged chips, resistors, capacitors, and other components is crucial to ensuring circuit functionality is restored. The choice of flux type is particularly important: no-clean solder wire facilitates quick rework, while water-soluble flux is suitable for high-purity requirements, but requires prompt cleaning to remove residue.

For troubleshooting assistance, solder wire can also be used in electronics repair to make temporary connections to test points or reinforce circuits, helping engineers quickly diagnose faults.

Solder Wire Handling Tips and Precautions

Temperature Control: Adjust the soldering iron temperature according to the melting point of the solder filament to avoid excessively high temperatures that may damage components or circuit boards.

Control the amount of solder: Too little solder will result in a cold joint, while too much can easily cause a short circuit or solder bridge.

Clean the solder joints: When using rosin residue or water-soluble flux, remove any residue promptly depending on the type of flux.

To prevent oxidation, keep the solder filament dry before use and store it in a sealed, moisture-proof container to extend its lifespan.

Common Problems and Safety Precautions for Solder Wire

In electronics manufacturing and repair, even if you choose high-quality solder filament, ignoring usage instructions, storage conditions, or safe handling can still lead to solder defects, equipment damage, or even personal injury. Therefore, understanding common solder filament issues and safety precautions is crucial for both technicians and purchasers.

Common Problems with Solder Wire

Cold Joints and False Joints

Causes: Inadequate soldering temperature, insufficient solder volume, too short a soldering time, or insufficient wetting of the solder joint. Symptoms: The solder joint may appear dull, or may experience poor contact with slight vibration or current flow.

Solution: Adjust the soldering iron temperature, increase the amount of solder, and ensure the pad is clean.

Solder Bridges and Short Circuits

Cause: Excessive solder wire or improper handling can cause molten solder to form conductive bridges between adjacent solder joints.

Symptoms: A short circuit may result in component burnout or system failure.

Solution: Use flux to control solder flow, or remove excess solder with a solder sucker or solder belt.

Solder Joint Cracks

Causes: Uneven solder shrinkage, rapid temperature changes, or mechanical stress on the solder joint.

Symptoms: Cracks appear on the solder joint surface, resulting in unstable conductivity.

Solution: Select the appropriate solder wire diameter and alloy, and control soldering temperature and speed.

Oxidation and Solder Aging

Cause: Improper storage of solder wire, moisture, or exposure to air.

Symptoms: The solder surface darkens, and wettability decreases after melting, making soldering difficult. Solution: Keep solder wire dry and store in sealed packaging. Use flux to clean the oxide layer as needed.

Safety Precautions for Using Solder Wire

Protective Measures: When using a soldering iron or soldering station, be aware that the tip of the soldering iron can reach temperatures exceeding 350°C and avoid contact with skin. Wear protective glasses during soldering to prevent solder splatter from damaging your eyes.

Ventilation and Hazardous Substance Control: Lead-containing solder or activated flux may produce fumes when melting. It is recommended to work in a well-ventilated environment or use a fume extraction device.

Clean your work surface and tools regularly to avoid prolonged exposure to lead or flux residue.

Storage Instructions: Solder wire should be stored in a cool, dry place, away from moisture, heat, and prolonged exposure to air. Core solder wire should be kept away from compression or bending to prevent flux loss or breakage.

Disposal: Lead-containing solder is considered hazardous waste and should be handled in strict accordance with environmental regulations to avoid environmental pollution. Lead-free solder and residual flux should also be collected separately to ensure compliance with environmental regulations.

Summary

Solder wire is an essential core material in electronics manufacturing and repair. Its quality, type, flux properties, and application methods directly impact soldering quality, electronic component lifespan, and production efficiency. From alloy composition, flux core type, and diameter specifications to production processes, storage management, and safe operation, every step requires strict control.

In practical applications, selecting the appropriate solder wire for different electronic products and industry requirements is key to improving soldering efficiency and ensuring electrical performance and mechanical reliability. Mastering proper solder wire usage techniques, maintenance measures, and troubleshooting common problems not only reduces production and repair costs but also ensures long-term stable equipment operation. A deep understanding of solder wire’s characteristics and applications will provide solid technical support for electronics manufacturing and repair, making soldering operations safer, more efficient, and more reliable.