Extracting gold from PCB boards has become a significant topic of interest due to the growing demand for precious metals and the need to address the increasing volume of electronic waste (e-waste) generated globally.

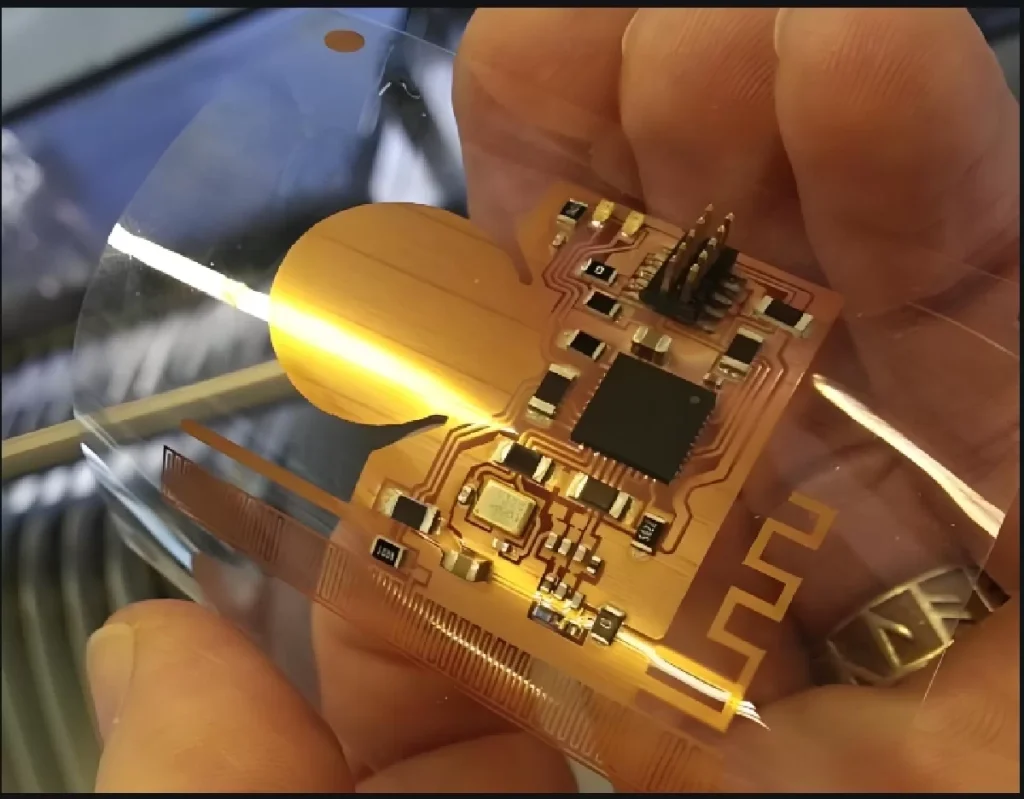

Printed Circuit Boards (PCBs) are an essential component of almost all electronic devices, including smartphones, computers, televisions, and industrial machinery. These boards contain various metals, including small amounts of gold, which is highly valued for its excellent electrical conductivity and resistance to corrosion. Although the amount of gold in each PCB is relatively small, the sheer volume of e-waste produced annually makes the extraction of gold from these boards potentially lucrative.

However, extracting gold from PCB boards is not a simple process; it requires specialized techniques, poses several environmental challenges, and necessitates a careful balance between profitability and sustainability. In this article, we will explore the different methods used for extracting gold from PCB boards, examine the associated challenges, and discuss the importance of adopting sustainable practices in this field.

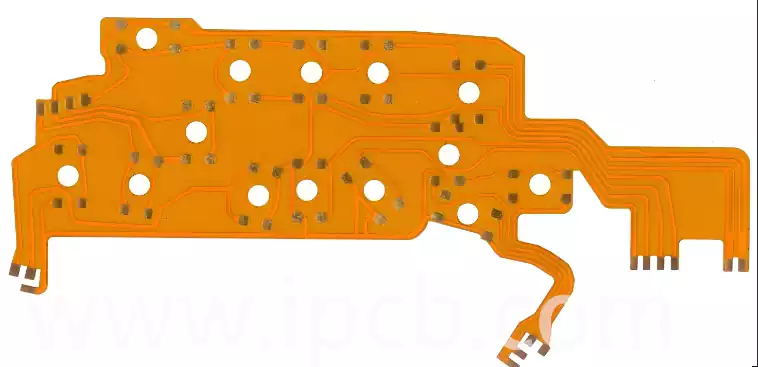

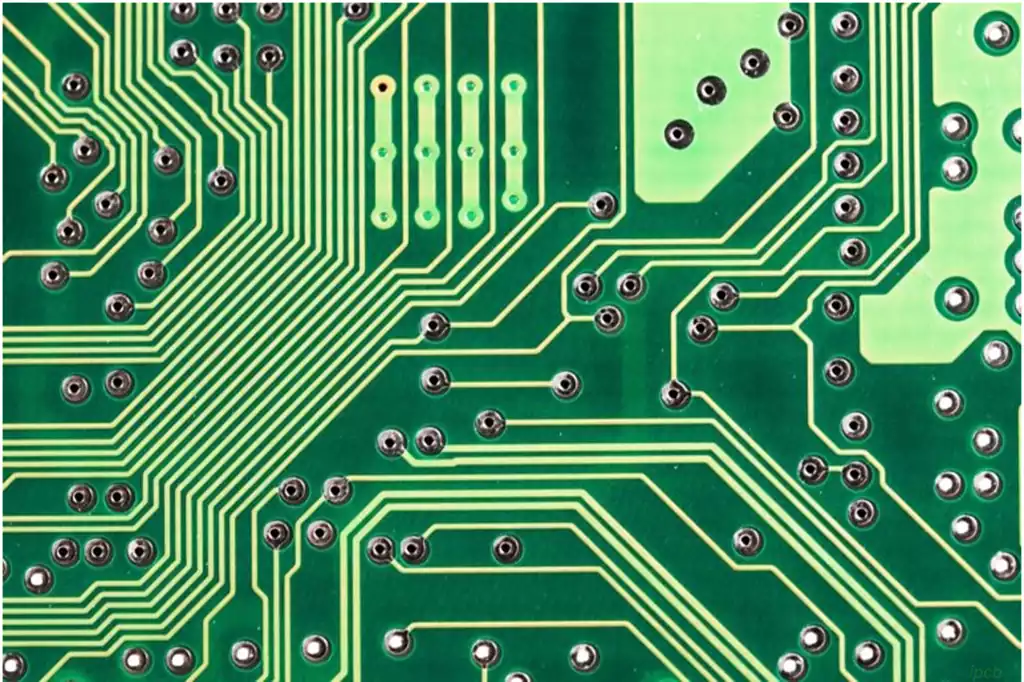

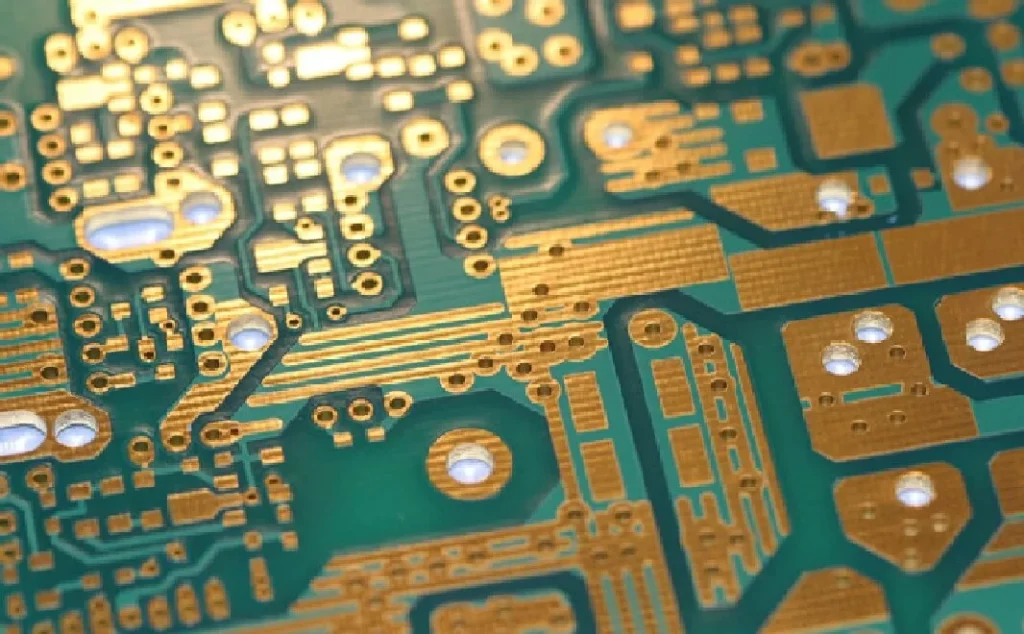

Understanding the Composition of PCB Boards

Before delving into the methods of extracting gold from PCB boards, it is crucial to understand the composition of these boards. PCBs are typically constructed from multiple layers, which include a fiberglass substrate, copper circuitry, and various other metals, such as tin, lead, and palladium, in addition to gold. The gold is usually found in the connectors, contact points, and sometimes in the plating of the copper circuitry. Although each PCB contains only a small amount of gold, the vast quantities of electronic devices discarded each year make the process of extracting gold from these boards economically viable. The challenge lies in efficiently extracting the gold without causing significant harm to the environment.

Methods of Extracting Gold from PCB Boards

Several methods are employed for extracting gold from PCB boards, each with its advantages and disadvantages. The most common techniques include chemical leaching, pyrometallurgical processing, electrochemical methods, and emerging biological methods.

Chemical Leaching

Chemical leaching is one of the most widely used methods for extracting gold from PCB boards. This process involves the use of strong chemicals, such as cyanide or aqua regia (a mixture of nitric acid and hydrochloric acid), to dissolve the gold present on the board. Once the gold is in solution, it can be precipitated out and recovered. Cyanide leaching is particularly effective and widely used in the mining industry for gold extraction; however, it is also highly toxic and poses significant environmental and health risks if not carefully managed. Aqua regia, while effective in dissolving gold, generates hazardous waste that requires proper disposal to prevent environmental contamination. Due to the environmental and safety concerns associated with chemical leaching, there is ongoing research into developing less toxic alternatives, such as thiosulfate leaching, which has shown promise in reducing the environmental impact of the extraction process.

Pyrometallurgical Processing

Pyrometallurgical processing is another method used to extract gold from PCB boards. This method involves subjecting the PCBs to high temperatures in a furnace, which causes the metals to melt and separate from the non-metallic components. The molten metals, including gold, are then collected and refined to separate the different metals. Pyrometallurgical processing is an efficient method for extracting gold from PCBs, but it is also energy-intensive and can release harmful pollutants into the atmosphere, such as dioxins and furans, which are toxic and pose significant health risks. Additionally, the high energy consumption associated with this method makes it less environmentally friendly compared to other extraction techniques. Despite these drawbacks, pyrometallurgical processing remains a widely used method due to its ability to process large volumes of e-waste efficiently.

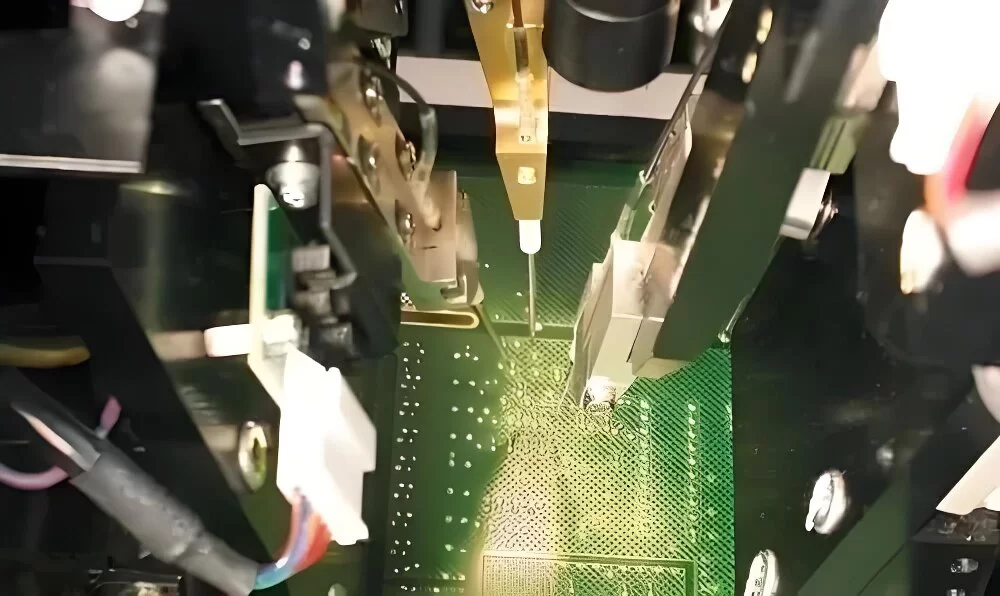

Electrochemical Methods

Electrochemical methods involve the use of an electrical current to extract gold from PCB boards. In this process, the PCBs are submerged in an electrolyte solution, and an electrical current is applied, causing the gold to dissolve into the solution. The dissolved gold can then be recovered by electroplating onto a cathode or by precipitation. Electrochemical methods are generally considered more environmentally friendly than chemical leaching, as they do not involve the use of toxic chemicals. However, these methods can be less efficient and may require longer processing times, which can be a drawback in large-scale operations. Additionally, the cost of setting up and maintaining electrochemical extraction systems can be higher than other methods, which may limit their adoption in some cases.

Biological Methods

In recent years, biological methods for extracting gold from PCB boards have gained attention as a more sustainable alternative to traditional extraction techniques. These methods involve the use of microorganisms, such as bacteria or fungi, that have the ability to break down PCB material and release gold. The process, known as bioleaching, is still in the experimental stage but has shown promise as a green alternative to chemical and pyrometallurgical methods. Bioleaching is environmentally friendly, as it does not produce toxic waste and operates at lower temperatures, reducing energy consumption. However, the main challenges with biological methods include the longer processing times required and the difficulty in scaling up the process for commercial use. Despite these challenges, ongoing research in this field may lead to the development of more efficient and scalable biological extraction methods in the future.

Challenges in Extracting Gold from PCB Boards

The extraction of gold from PCB boards presents several challenges, both technical and environmental. These challenges include the complexity of PCB composition, the environmental and health risks associated with extraction methods, and the economic viability of the process.

Complexity of PCB Composition

PCBs are composed of multiple layers of materials, including metals, plastics, and other organic compounds. The complexity of this composition makes it challenging to efficiently separate gold from other materials. Mechanical and pyrometallurgical methods, in particular, can struggle with the separation of metals, leading to the potential loss of valuable materials. Additionally, the presence of hazardous substances, such as lead and mercury, in some PCBs requires careful handling and disposal to prevent environmental contamination. The complex nature of PCBs means that extracting gold requires specialized techniques and equipment, which can add to the cost and complexity of the process.

Environmental and Health Risks

The environmental and health risks associated with extracting gold from PCB boards are significant. Chemical leaching, for example, involves the use of toxic chemicals such as cyanide and aqua regia, which can pose serious risks to workers and the environment if not properly managed. Cyanide is highly toxic and can cause severe environmental damage if released into water sources. Aqua regia, while effective in dissolving gold, produces hazardous waste that requires careful disposal. Pyrometallurgical processing, on the other hand, can release harmful pollutants into the atmosphere, contributing to air pollution and posing health risks to workers and nearby communities. The disposal of e-waste, including the remnants of PCB boards after gold extraction, also presents a significant environmental challenge. Improper disposal can lead to the leaching of toxic substances into the soil and groundwater, further exacerbating environmental damage.

Economic Viability

The economic viability of extracting gold from PCB boards depends on several factors, including the efficiency of the extraction method, the cost of raw materials, and the market price of gold. In some cases, the cost of extraction may outweigh the value of the recovered gold, particularly when dealing with low-grade PCBs or small quantities of material. Additionally, the fluctuating price of gold on the global market can impact the profitability of gold extraction operations, making it a potentially risky venture for businesses. To improve the economic viability of gold extraction from PCBs, researchers are exploring new methods and technologies that can increase efficiency and reduce costs. These include advances in recycling technology, automation, and the use of alternative leaching agents that are less expensive and more environmentally friendly.

Sustainability and the Future of Gold Extraction

As concerns about e-waste and resource depletion continue to grow, there is increasing pressure to develop more sustainable methods for extracting gold from PCB boards. Several approaches are being explored to achieve this goal, including the development of improved recycling technologies, the adoption of green chemistry practices, and the promotion of a circular economy.

Improved Recycling Technologies

Advancements in recycling technologies are making it possible to recover gold and other valuable metals from e-waste more efficiently and with less environmental impact. For example, new methods of mechanical separation and refining are being developed to improve the recovery rates of gold from PCB boards while minimizing the use of toxic chemicals. These technologies are designed to be more cost-effective and scalable, making them accessible to a broader range of industries. Additionally, research into automated recycling processes aims to increase the speed and efficiency of gold recovery, further enhancing the economic viability of extraction operations.

Green Chemistry

Green chemistry is an emerging field that focuses on developing chemical processes that are less harmful to the environment. In the context of gold extraction, green chemistry aims to reduce or eliminate the use of hazardous chemicals like cyanide and aqua regia. Researchers are exploring alternative leaching agents, such as thiosulfate or thiourea, which are less toxic and more environmentally friendly. While these alternatives show promise, further research is needed to optimize their efficiency and cost-effectiveness. The adoption of green chemistry practices in gold extraction could significantly reduce the environmental footprint of the industry, making it a more sustainable option for the future.

Circular Economy

The concept of a circular economy, where resources are reused and recycled rather than discarded, is gaining traction in the electronics industry. By promoting the recycling of PCB boards and the recovery of valuable metals like gold, the circular economy can help reduce the environmental impact of electronic waste and conserve precious resources. Companies are increasingly recognizing the value of a circular approach and are investing in technologies and processes that support this model. The adoption of a circular economy framework could lead to more sustainable gold extraction practices, reducing the need for raw material extraction and minimizing the overall environmental impact of the electronics industry.

Legislation and Regulations

Government legislation and regulations play a crucial role in promoting sustainable gold extraction practices. Stricter environmental regulations and e-waste management policies can incentivize companies to adopt cleaner extraction methods and invest in recycling technologies. Additionally, international agreements and standards, such as the Basel Convention, aim to regulate the transboundary movement of hazardous waste, including e-waste, and ensure its environmentally sound management. By enforcing these regulations, governments can help reduce the environmental and health risks associated with gold extraction from PCB boards and encourage the development of more sustainable practices.

Conclusion

Extracting gold from PCB boards is a complex and challenging process that requires a careful balance between efficiency, environmental responsibility, and economic viability. While traditional methods like chemical leaching and pyrometallurgical processing have been widely used, they come with significant environmental and health risks. As the demand for gold continues to grow and concerns about e-waste and resource depletion mount, there is an urgent need to develop more sustainable extraction methods. Advances in recycling technology, green chemistry, and the adoption of a circular economy are all promising avenues for achieving this goal. By prioritizing sustainability and investing in new technologies, the gold extraction industry can play a vital role in reducing e-waste, conserving resources, and protecting the environment for future generations