What is FR-4 Circuit Board? FR-4 is a code name for a fire-resistant material grade, representing a material specification in which resin materials must be able to self extinguish after combustion. It is not a material name, but a material grade. Therefore, there are many types of FR-4 grade materials used in general circuit boards, but most of them are composite materials made of Tera Function epoxy resin combined with Filler and fiberglass. In the PCB industry, it is customary to use circuit boards that comply with this FR-4 epoxy fiberglass cloth, which is called FR-4 PCBs. So FR4 is not only the name of a type of PCB circuit board, but also a fire-resistant material with a fire rating.

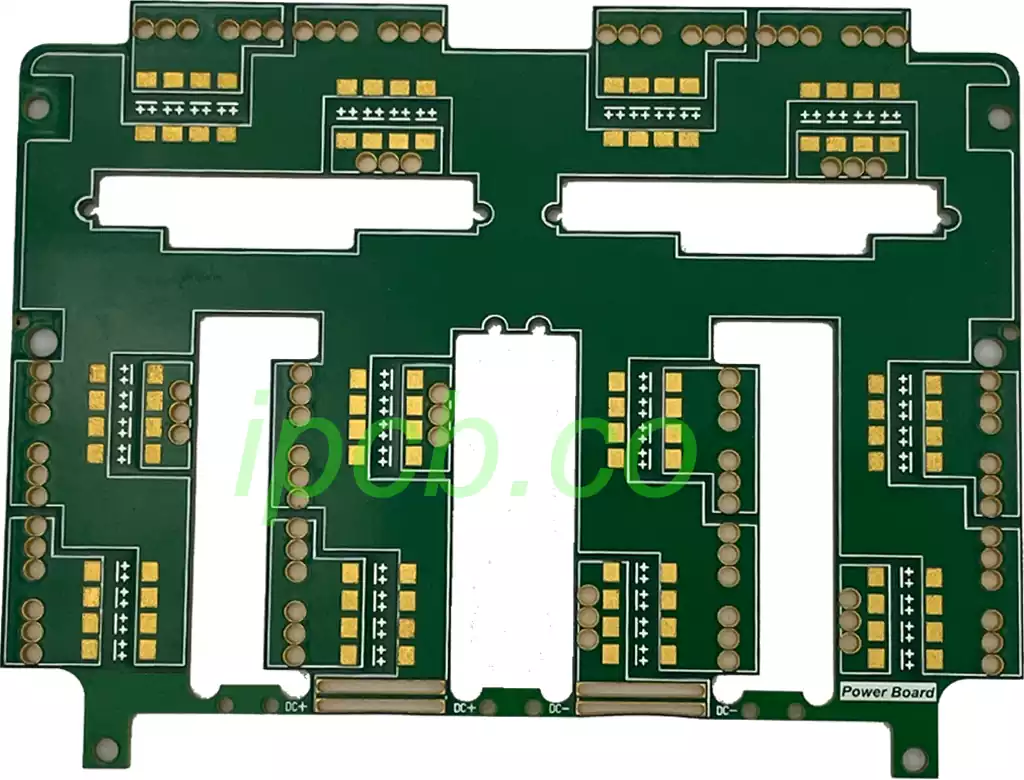

The surface colors of FR-4 epoxy glass cloth circuit board include yellow FR-4, white FR-4, black FR-4, blue FR-4, etc. They have high mechanical and dielectric properties, good heat and moisture resistance, and good machinability.

But as consumer devices move towards smaller, lighter, and thinner sizes, the use of FR-4 circuit board is also increasing. With the widespread use of PCBs with standard thicknesses ranging from 1.6 to 0.4 millimeters, the mechanical strength and moisture resistance of paper substrates have become a problem. In addition, paper substrates are not suitable for the production of multi-layer circuit board, and with the development of equipment miniaturization, the PCB wiring density is increasing, and the market share of multi-layer circuit boards is also increasing. Therefore, although the cost of FR-4 circuit boards is relatively high, consumer products are still gradually shifting towards FR-4 circuit board.

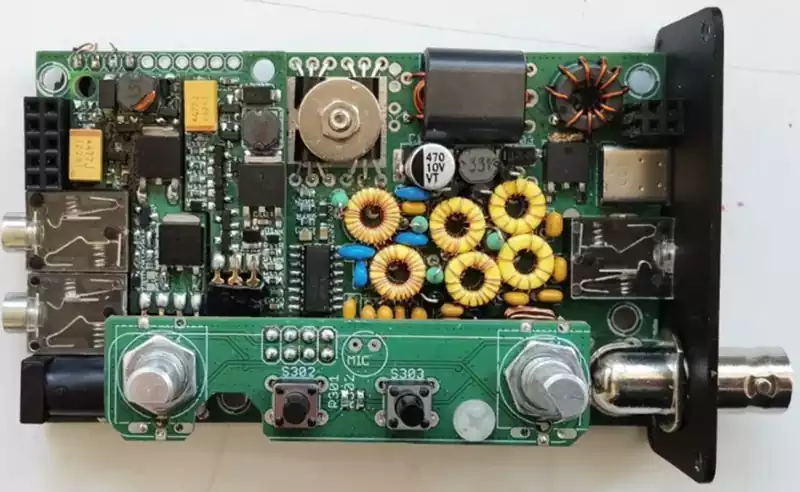

We see a circuit board with a specification of FR4 T: 1.0 D/S, which means it uses FR-4 material, T: 1.0 means a thickness of 1mm, and D/S means a double-sided circuit board.

Advantages of FR4 circuit board material

Electrical performance: Excellent electrical performance, including low warping, low water absorption, low volume resistance coefficient, and low dielectric loss, can provide reliable signal transmission and power supply.

Mechanical strength: With high mechanical strength, it can withstand mechanical stress under various environmental conditions, ensuring the stability and reliability of printed circuit boards.

Heat resistance: With high heat resistance, it can maintain stable performance at high temperatures and adapt to various environmental conditions.

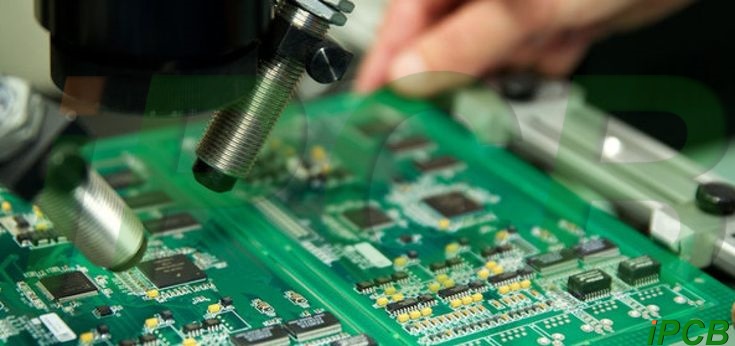

Processability: Easy to process, capable of drilling, cutting, bending and other operations according to design requirements, with flexibility and plasticity.

Disadvantages of FR4 circuit board material

Higher cost: The production of FR4 PCB requires the use of high-precision equipment and materials, resulting in relatively high costs.

Non reusable: Once manufactured, it is difficult to reuse, which has a certain impact on environmental protection.

Not fully compliant with halogen-free requirements: FR4 materials contain a certain amount of halogens, which may have certain limitations for halogen-free application scenarios.

Widely applicable: The application scenarios of FR4 PCB are very extensive, involving a wide range of fields.

Due to the widespread application of FR4 circuit board in various fields.

Electronic products: FR4 material is widely used in the manufacturing of Printed Circuit Board. PCB is an indispensable component of modern electronic products, and FR4, as an insulating material, can be used as the substrate for PCB to support and isolate electronic components.

Communication equipment: Due to its low dielectric constant and good insulation performance, FR4 circuit board materials are widely used as insulation materials for antenna bases, RF modules, and microwave devices in communication equipment.

Automotive industry: FR4 circuit board materials are still being applied in the automotive industry, such as manufacturing automotive instrument panels, in car entertainment systems, etc. Its heat resistance and mechanical strength enable it to adapt to the complex working environment inside the car.

Other fields: In addition to the above applications, FR4 circuit board materials can also be used in aerospace, medical equipment, industrial equipment and other fields to meet the needs of high-performance insulation materials in different fields.

iPCB supplies various FR-4 circuit board, including solder mask colors: green, black, blue, white, yellow, and red. Character colors: white, yellow, black. Surface technology: tin spraying, lead-free tin spraying, ENIG, gold plating, OSP. We guarantee that PCBs have good quality, welcome inquiries.