The production process of electronic manufacturing products usually includes product design, raw material procurement, parts processing, assembly production, quality inspection, packaging and shipment. Below, Mia will introduce in detail each aspect of electronic product production.

In this era of popular electronic products, ranging from smart bracelets and mobile phones to computers, televisions, etc., we are no longer surprised, and the prices are already very cheap. However, perhaps most people have not carefully thought about how they are produced.

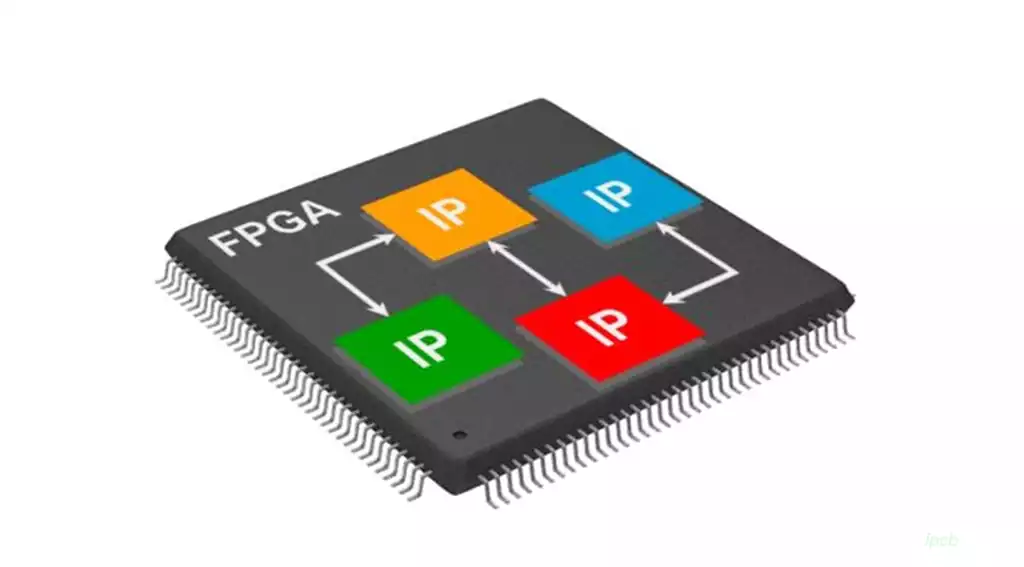

The first is the product design stage, which is the first step in the production of electronic products. Product design includes two aspects: appearance design and structural design. The appearance design requires the product to be beautiful and elegant in appearance and conform to ergonomics. The structural design requires the product to be reasonably structured and easy to assemble and maintain.Product design requires reasonable planning and design based on market demand and technical requirements to ensure that the function and performance of the product meet the expected goals.

Next is the procurement of raw materials. Raw material procurement is an important part of production, and the quality of raw materials directly affects the quality of products. When purchasing raw materials, it is necessary to choose suppliers with reliable quality and reasonable prices, establish stable raw material supply channels, and ensure adequate supply of raw materials required for production. To ensure product quality and performance, procurement teams need to work with suppliers to select appropriate materials and components. Not only do they need to consider price and delivery time, they also need to evaluate the supplier’s reputation and product quality.

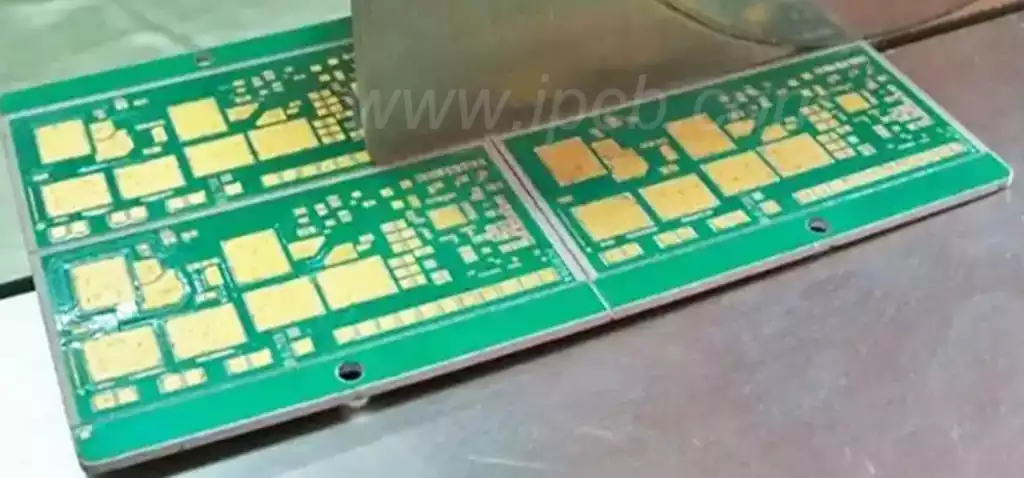

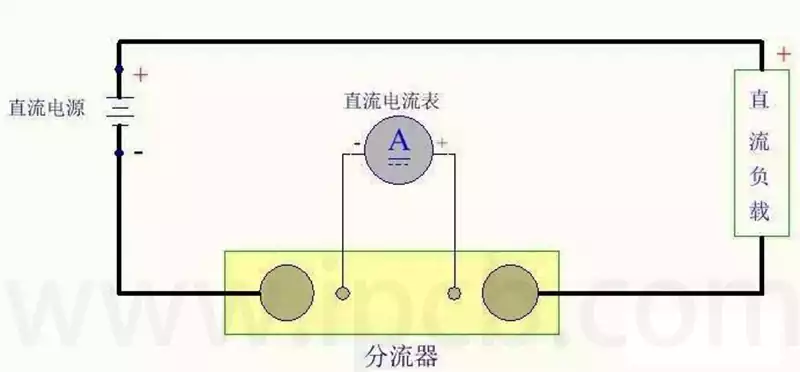

Then comes the parts processing stage. At this stage, raw materials are processed into various parts and components that meet product requirements. The processing process needs to be carried out in strict accordance with product design requirements to ensure the accuracy and quality of parts. At the same time, strict quality control is required during the electronic manufacturing, and problems that arise during processing must be discovered and dealt with in a timely manner to ensure that the quality of parts meets the requirements.

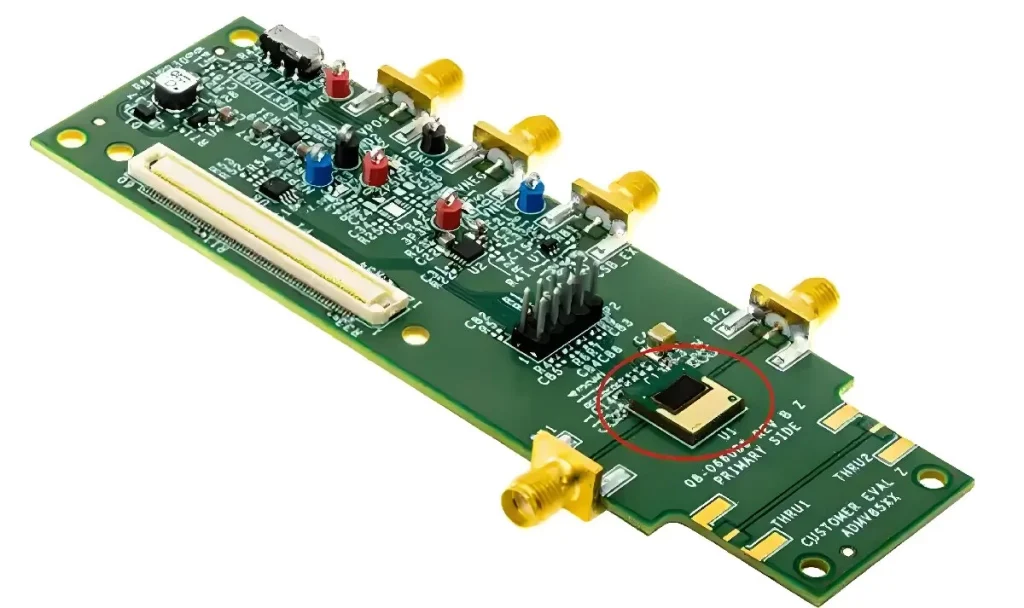

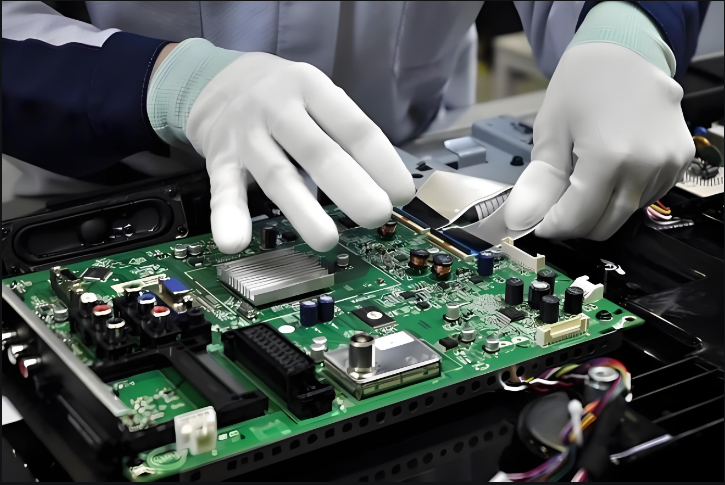

This is followed by the assembly and production process. At this stage, individual components are assembled into finished products. Assembly production needs to be carried out in strict accordance with the product assembly process to ensure product assembly quality and efficiency. At the same time, problems that arise during the assembly process must be dealt with in a timely manner to ensure the smooth progress of product assembly.

Next is the quality inspection link. Quality inspection is an important link in the production process. Through comprehensive and strict inspection of products, we ensure that the quality of the products meets standard requirements. Quality inspection includes appearance inspection, functional inspection, performance inspection and other aspects. Through strict quality inspection, unqualified products are screened out to ensure that qualified products leave the factory. Qualified products will be packaged, including product shells, accessories and instructions. The product will then be ready to be shipped to distributors or sold directly.

The last step is packaging and shipping. At this stage, the product is packaged and shipped. The packaging must be beautiful, sturdy, and easy to transport to ensure that the product is not damaged during transportation. At the same time, final inspection is carried out on the products before shipment to ensure that the quality of the products meets the requirements. Product Delivery and After-Sales Service Finally, the products are delivered to distributors or sold directly to end users. Along with the delivery of products, companies also need to provide after-sales services, including warranty, technical support and repairs. This is to ensure the quality and performance of the product during use and to provide a satisfactory user experience.

To sum up, the electronic product production process is a complex and rigorous process: it requires close cooperation and coordination of multiple teams. From product design to final delivery, each step requires strict control and testing to ensure product quality and performance. Every link needs to be carried out in strict accordance with the requirements to ensure that the quality and performance of the product meet the expected goals. Only in this way can high-quality electronic products be produced to meet the needs of the market and consumers. With the continuous advancement of science and technology, the production process of Electronic Manufacturing products is also constantly innovating and developing: providing users with better products.