PCB manufacturing capability refers to the ability and stability requirements for evaluating and controlling key parameters in the PCB manufacturing process. These parameters include material selection, design specifications, processing technology, and quality control. The quality and reliability of the final product are directly affected by the requirements for PCB manufacturing capability.

Material selection is an important step in the PCB manufacturing capability. The selection of materials should be determined based on design requirements and application scenarios. Common PCB materials include FR-4 fiberglass laminates, polyimide (PI) boards, plastic CCL, and metal substrates. Different materials have different properties and characteristics, and the process capability requirements should ensure that the selected materials meet the design and quality requirements.

Design specifications are also one of the key requirements for PCB manufacturing capability, which involves the hierarchical structure, line width and spacing, pad dosage, layout rules, and other aspects of the Printed Circuit Board. The design specifications should be matched with the PCB manufacturing process to ensure the controllability and stability of the manufacturing process. The quality of design specifications directly affects the process capability and product performance of PCB Circuit Boards.

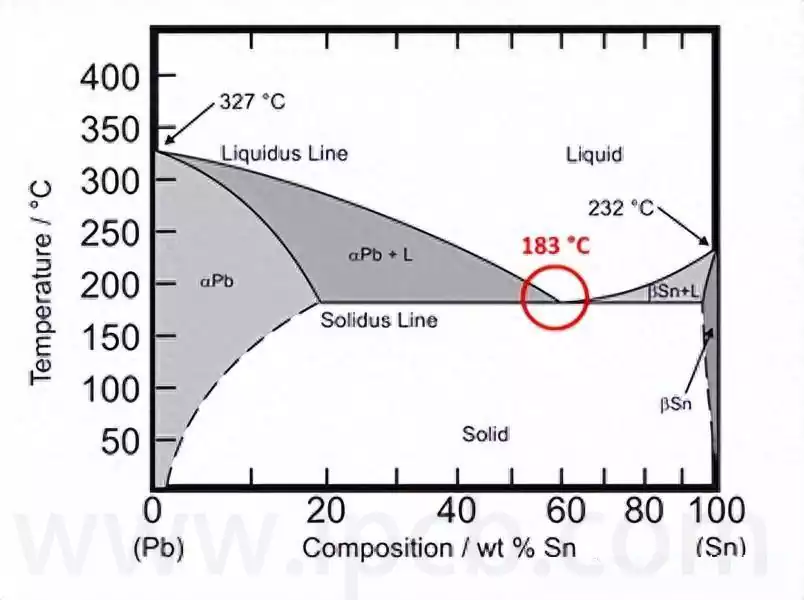

Processing technology is the core link in the PCB manufacturing capability. The processing technology involves the preparation, molding, punching, cutting, pressing, drilling, and copper plating of PCBs. The process capability requirement should ensure the accuracy and stability of the processing technology to ensure the accuracy, reliability, and durability of the Circuit Board.

Quality control is an important link in the PCB manufacturing capability. Quality control involves the measurement, analysis, and monitoring of various indicators of PCB. The process capability requirement should ensure the effectiveness and stability of quality control. Common quality control indicators include PCB board size error, line width and distance error, PCB thickness error, surface smoothness, etc.

In response to these requirements, process capability assessment is one of the methods for evaluating process capability. Process capability assessment is a statistical analysis of process data to determine the stability and controllability of the process. Common process capability evaluation methods include Process Capability Index (Cpk), Process Performance Index (Ppk), and Process Cross Performance Index (Pp/Ppk).

The PCB manufacturing capability requirements vary for different application scenarios and requirements. For example, in high-frequency applications, high requirements are placed on the signal loss and transmission characteristics of PCB boards. In high reliability applications, there is a high demand for the reliability and durability of PCB Circuit Boards. When meeting different application scenarios and requirements, the process capability requirements should comprehensively consider the requirements of material selection, design specifications, processing technology, and PCB quality control.

Regarding the PCB manufacturing capability of iPCB, please download: PCB Manufacturing Capability DataSheet