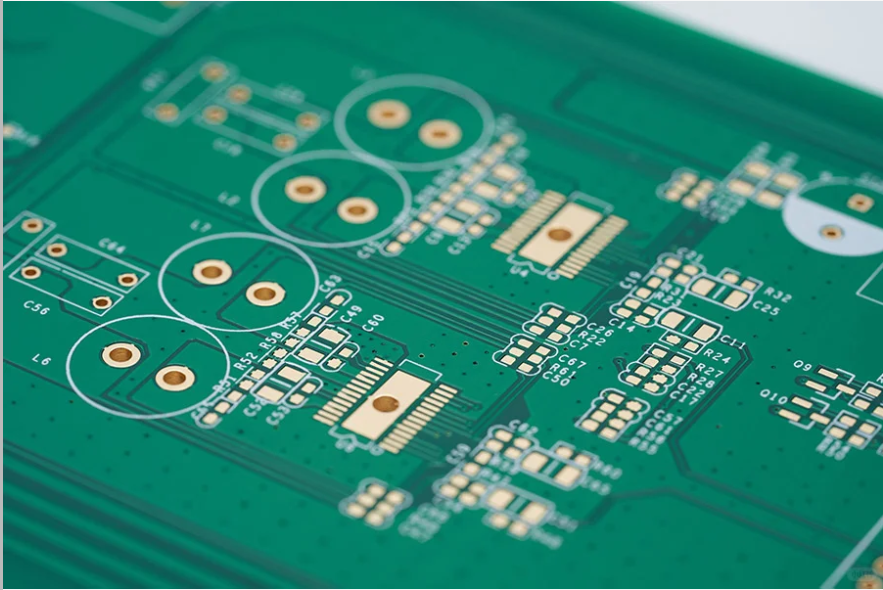

The Printed Circuit Board (PCB) is the heart of modern air conditioning units, playing a crucial role in their functionality and efficiency. Despite its importance, many users and even some technicians often overlook the complexities and critical functions of the aircon PCB board. This article aims to provide a comprehensive understanding of the aircon PCB board, covering its components, functions, common issues, and tips for maintenance and troubleshooting.

Introduction to Aircon PCB Boards

Air conditioning units have evolved significantly over the years, incorporating advanced electronics to enhance performance and energy efficiency. At the core of these advancements is the aircon PCB board. This component serves as the control center of the air conditioner, managing everything from temperature regulation to fan speed and compressor operation.

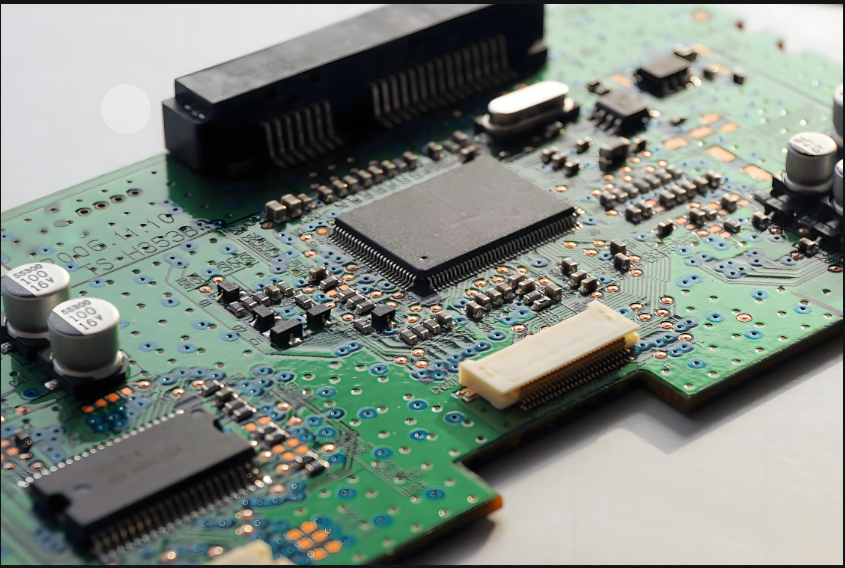

The PCB board in an air conditioner is a sophisticated assembly of various electronic components, including microcontrollers, relays, sensors, and capacitors. These components work in unison to ensure the air conditioner operates smoothly and responds accurately to user inputs and environmental changes.

Components of an Aircon PCB Board

Microcontroller

The microcontroller is often referred to as the brain of the PCB board. It is a compact integrated circuit designed to govern the functions of the air conditioning unit by executing programmed instructions. The microcontroller processes inputs from various sensors and user interfaces and controls the operation of other components accordingly.

For example, when you set a desired temperature on your air conditioner’s remote control, the microcontroller receives this input and processes it. It then signals the compressor to start or stop, adjusts the fan speed, and monitors the room temperature to maintain the set point. Modern microcontrollers are highly efficient and capable of performing complex tasks, such as energy management and error diagnostics.

Relays

Relays are electromechanical switches used to control high-power components like compressors and fan motors. They act as intermediaries between the low-power signals from the microcontroller and the high-power components. When the microcontroller sends a signal to activate the compressor, the relay closes the circuit, allowing the necessary power to flow to the compressor.

Relays are crucial for the reliable operation of the air conditioning unit. They are designed to handle high currents and voltages, ensuring that the system operates safely and efficiently. However, relays can wear out over time due to the mechanical nature of their operation, leading to potential failures.

Sensors

Sensors play a vital role in the operation of the air conditioning unit by providing real-time data to the microcontroller. Common sensors used in air conditioners include temperature sensors, humidity sensors, and pressure sensors.

Temperature sensors monitor the ambient and room temperatures, allowing the microcontroller to adjust the cooling output to maintain the desired temperature. Humidity sensors measure the moisture level in the air, helping the system to optimize dehumidification processes. Pressure sensors are used to monitor the refrigerant pressure within the system, ensuring safe and efficient operation.

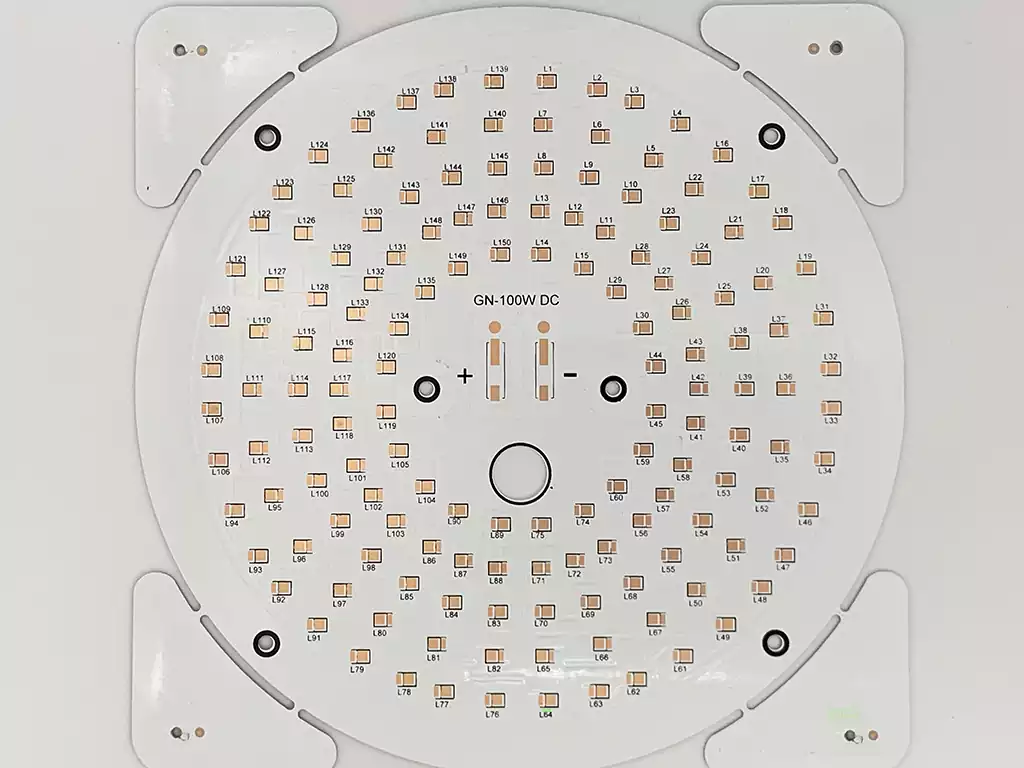

Capacitors

Capacitors are essential components that store and release electrical energy, helping to regulate voltage and smooth out fluctuations in the power supply. In air conditioning units, capacitors are used in various circuits, including the compressor and fan motor circuits.

Capacitors improve the efficiency and reliability of the air conditioning unit by providing a stable power supply to the components. They also play a critical role in starting the compressor and fan motors, which require a significant amount of power to initiate operation.

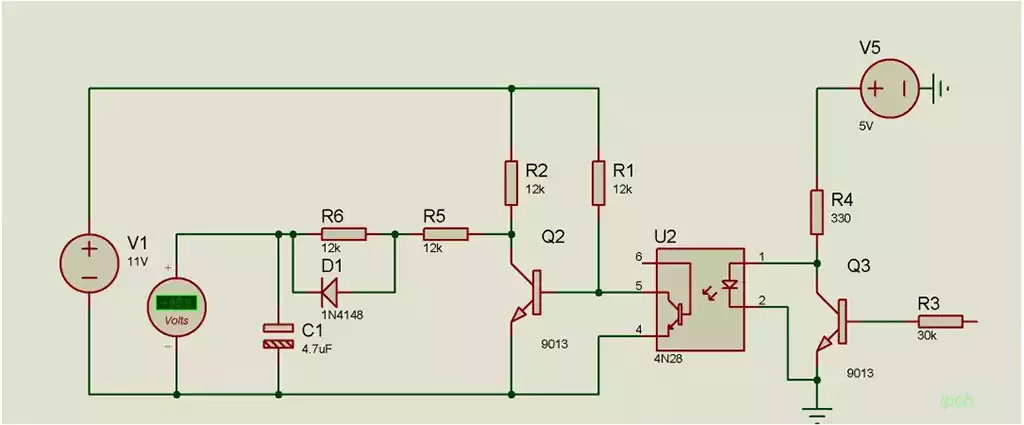

Diodes and Transistors

Diodes and transistors are semiconductor devices that control the direction and amplification of electrical signals within the PCB. Diodes allow current to flow in one direction only, providing protection against reverse polarity and ensuring correct current flow in the circuit.

Transistors are used to amplify and switch electronic signals. In air conditioning units, transistors are commonly used in the control circuits of the PCB board. They enable the microcontroller to interface with other components and control their operation effectively.

Functions of the Aircon PCB Board

The aircon PCB board performs several vital functions that are essential for the efficient operation of the air conditioning unit:

Temperature Regulation

One of the primary functions of the aircon PCB board is to regulate the temperature within the conditioned space. The PCB board achieves this by processing data from temperature sensors and adjusting the operation of the compressor and fan accordingly.

When the room temperature rises above the set point, the microcontroller signals the compressor to start, initiating the cooling process. The fan speed is also adjusted to enhance airflow and expedite cooling. Once the desired temperature is reached, the microcontroller shuts off the compressor to conserve energy. This continuous cycle ensures that the room temperature remains within the desired range.

Compressor Control

The compressor is the heart of the air conditioning unit, responsible for compressing the refrigerant and facilitating heat exchange. The aircon PCB board controls the operation of the compressor, ensuring it runs efficiently and cycles on and off as needed.

The microcontroller monitors various inputs, including temperature, pressure, and user settings, to determine when the compressor should be activated or deactivated. By optimizing the compressor’s operation, the PCB board helps to conserve energy and prolong the life of the air conditioning unit.

Fan Speed Control

The fan plays a crucial role in distributing cool air throughout the room and facilitating heat exchange within the air conditioning unit. The aircon PCB board controls the fan speed based on cooling demand and ambient conditions.

For instance, during high cooling demand, the microcontroller increases the fan speed to enhance airflow and improve cooling efficiency. Conversely, when the cooling demand is low, the fan speed is reduced to conserve energy and reduce noise. This dynamic control of the fan speed ensures optimal performance and comfort.

Error Detection and Diagnostics

Modern aircon PCB boards are equipped with advanced diagnostic capabilities that detect and report errors or malfunctions within the air conditioning system. These diagnostic features are critical for quick troubleshooting and repair, helping to minimize downtime and maintain efficient operation.

When an error is detected, the PCB board generates an error code that is displayed on the user interface. Technicians can use these error codes to identify the nature and location of the problem, enabling prompt and accurate repairs. Some air conditioning units also have self-diagnostic modes that allow users to perform basic troubleshooting without professional assistance.

Common Issues with Aircon PCB Boards

Despite their robust design, aircon PCB boards can encounter various issues that affect the performance of the air conditioning unit. Some common problems include:

Component Failure

Individual components of the PCB board, such as capacitors, relays, or microcontrollers, can fail due to age, electrical surges, or manufacturing defects. Component failure is one of the most common causes of PCB board malfunctions and can lead to issues such as intermittent operation, reduced performance, or complete system failure.

For example, a failed capacitor may cause the compressor to struggle to start, resulting in poor cooling performance. Similarly, a faulty relay can prevent the fan motor from operating, leading to inadequate airflow and inefficient cooling.

Solder Joint Issues

Poor solder joints or cracks can lead to intermittent connections, causing erratic behavior or complete failure of the PCB board. Solder joints are the points where electronic components are connected to the PCB, and they can degrade over time due to thermal expansion and contraction, vibration, or mechanical stress.

Intermittent connections can result in sporadic operation, where the air conditioning unit may start and stop unpredictably. In severe cases, broken solder joints can cause the PCB board to fail completely, rendering the air conditioner inoperative.

Corrosion

Exposure to moisture or corrosive environments can damage the PCB board, leading to short circuits or component failures. Corrosion can occur due to high humidity, water leaks, or the presence of corrosive substances in the air.

Corrosion can cause the metal traces on the PCB to degrade, disrupting electrical connections and leading to malfunctions. It can also affect the performance of components such as sensors and relays, resulting in unreliable operation and reduced efficiency.

Software Glitches

Firmware or software issues within the microcontroller can result in improper operation or failure to respond to user inputs. Software glitches can be caused by bugs in the firmware, improper programming, or compatibility issues with other components.

For example, a software glitch may cause the microcontroller to misinterpret sensor data, leading to incorrect temperature regulation or fan speed control. In some cases, updating the firmware can resolve these issues and restore proper operation.

Maintenance and Troubleshooting Tips

Proper maintenance and timely troubleshooting are essential to ensure the longevity and efficient operation of the aircon PCB board. Here are some tips to help you keep your PCB board in optimal condition:

Regular Cleaning

Dust and debris can accumulate on the PCB board, causing overheating and potential short circuits. Regularly clean the PCB board with compressed air or a soft brush to prevent buildup. It is essential to perform this cleaning with the power off to avoid electrical hazards.

Inspect for Corrosion

Periodically check the PCB board for signs of corrosion, especially if the air conditioner is located in a humid or corrosive environment. Clean any corroded areas with a suitable electronic cleaner and ensure the unit is adequately protected from moisture.

Check Solder Joints

Inspect the solder joints on the PCB board for cracks or poor connections. Re-solder any questionable joints to ensure reliable electrical connections. A magnifying glass can be helpful for identifying small cracks or defects in the solder joints.

Monitor Component Health

Use a multimeter to check the health of key components such as capacitors and relays. Replace any components that show signs of wear or failure. Capacitors, for instance, can be tested for their capacitance value and any signs of leakage or bulging.

Update Firmware

If the air conditioning unit’s PCB board uses firmware, check for updates from the manufacturer. Updating the firmware can resolve software glitches and improve performance. It is essential to follow the manufacturer’s instructions carefully when performing firmware updates to avoid damaging the PCB board.

Use Surge Protection

Protect the air conditioning unit from electrical surges by using a surge protector. This can prevent damage to the PCB board and other electronic components. Surge protectors can absorb excess voltage during electrical spikes, safeguarding the delicate electronics within the air conditioner.

Professional Inspection

If you encounter persistent issues with the air conditioning unit, seek the assistance of a professional technician. They have the tools and expertise to diagnose and repair PCB board problems effectively. Regular professional inspections can also help identify potential issues before they lead to significant failures.

Advances in Aircon PCB Technology

The field of aircon PCB technology is continuously evolving, with new advancements aimed at improving performance, energy efficiency, and reliability. Let’s explore some of the latest developments in aircon PCB technology.

Smart PCB Boards

Smart PCB boards are equipped with advanced sensors and communication capabilities, allowing them to integrate seamlessly with smart home systems and IoT (Internet of Things) devices. These PCB boards can be controlled remotely via smartphone apps, enabling users to monitor and adjust their air conditioning units from anywhere.

Smart PCB boards also have enhanced diagnostic features, providing real-time alerts and detailed error reports to users and technicians. This technology enables proactive maintenance and quicker resolution of issues, improving overall system reliability.

Energy-Efficient Designs

Modern aircon PCB boards are designed with energy efficiency in mind. They incorporate advanced algorithms and power management techniques to optimize the operation of the compressor and fan motors. By reducing energy consumption, these PCB boards help lower utility bills and minimize the environmental impact of air conditioning systems.

For example, variable speed compressors controlled by advanced PCB boards can adjust their output based on cooling demand, providing precise temperature control and significant energy savings compared to traditional fixed-speed compressors.

Enhanced Durability and Reliability

New materials and manufacturing techniques are being used to enhance the durability and reliability of aircon PCB boards. These advancements include improved soldering methods, corrosion-resistant coatings, and high-quality components that can withstand harsh operating conditions.

Enhanced durability ensures that air conditioning units can operate reliably over extended periods, reducing the need for frequent repairs and replacements. This is particularly important in commercial and industrial settings where downtime can have significant financial implications.

Integration with Renewable Energy Sources

As the world moves towards sustainable energy solutions, aircon PCB boards are being designed to integrate with renewable energy sources such as solar and wind power. These PCB boards can manage power inputs from renewable sources and optimize the operation of the air conditioning unit accordingly.

For instance, during peak solar generation periods, the PCB board can increase the cooling output to take advantage of the abundant energy, while reducing the load on the grid. This integration helps reduce reliance on non-renewable energy sources and promotes the use of clean energy technologies.

Future Trends in Aircon PCB Technology

The future of aircon PCB technology looks promising, with several trends poised to shape the industry in the coming years. Let’s explore some of these trends and their potential impact on air conditioning systems.

Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are set to revolutionize aircon PCB technology. By leveraging AI and ML algorithms, PCB boards can analyze vast amounts of data from sensors and user inputs to optimize the operation of the air conditioning unit.

AI-driven PCB boards can learn user preferences, predict cooling demands, and adjust settings automatically for maximum comfort and energy efficiency. They can also detect anomalies and predict potential failures, enabling proactive maintenance and reducing the likelihood of unexpected breakdowns.

Advanced Connectivity and IoT Integration

The integration of IoT (Internet of Things) technology with aircon PCB boards is expected to continue, enhancing connectivity and remote control capabilities. Future PCB boards will have more robust communication protocols, allowing them to interact seamlessly with other smart devices and home automation systems.

This advanced connectivity will enable users to create personalized cooling schedules, monitor energy consumption, and receive real-time alerts about system performance. It will also facilitate remote diagnostics and troubleshooting by technicians, improving service efficiency and reducing downtime.

Miniaturization and Compact Designs

As electronic components become smaller and more efficient, aircon PCB boards are expected to undergo significant miniaturization. Compact PCB designs will enable the development of smaller and more efficient air conditioning units, ideal for modern living spaces with limited room.

Miniaturization will also allow for more flexible installation options, such as integration into architectural elements or furniture. This trend will enhance the aesthetic appeal of air conditioning systems while maintaining their functionality and performance.

Conclusion

The aircon PCB board is an integral component of modern air conditioning units, responsible for their efficient and reliable operation. Understanding its components, functions, and common issues can help users and technicians maintain and troubleshoot these critical devices effectively. By following proper maintenance practices and addressing issues promptly, you can ensure the longevity and optimal performance of your air conditioning unit.

Whether you are a homeowner, technician, or industry professional, a solid grasp of aircon PCB boards is essential for keeping your cooling systems running smoothly and efficiently. As technology continues to advance, staying informed about the latest developments and trends in aircon PCB technology will help you make the most of your air conditioning systems and contribute to a more sustainable future.

By diving deep into the intricacies of aircon PCB boards and exploring real-world examples, case studies, and future trends, this article aims to provide a comprehensive understanding of these essential components. With proper maintenance and timely troubleshooting, you can ensure that your air conditioning units remain reliable, efficient, and capable of providing optimal comfort for years to come.

4o