The development of electronic systems has created the need for advanced power management solutions, which are essential in ensuring that devices function optimally. At the core of these systems is the apex regulator PCB. Designed to regulate and maintain stable voltage levels, these printed circuit boards play a crucial role in safeguarding electronic components from voltage fluctuations and preventing potential damage. As devices become more sophisticated, requiring consistent power to operate effectively, apex regulator PCBs have become indispensable in modern electronics. This article explores the design, functioning, and extensive applications of apex regulator PCBs, illustrating their importance in maintaining efficiency and longevity in various electronic devices.

What is an Apex Regulator PCB?

An apex regulator PCB is a type of printed circuit board equipped with voltage regulation circuits that ensure stable voltage supply across electronic systems. These PCBs are critical in applications that require consistent power, protecting sensitive components from voltage irregularities that could lead to malfunction or permanent damage. Whether in consumer electronics, industrial equipment, or automotive systems, the need for stable voltage makes apex regulator PCBs essential in ensuring smooth and reliable performance.

One of the key functions of the apex regulator PCB is to control the voltage level that flows to various components within the system. Voltage fluctuations are common in electronic devices due to variations in power supply, environmental conditions, or changes in power demands. These fluctuations can have adverse effects on the operation of electronic systems, causing interruptions, reduced performance, or even complete failure. The apex regulator PCB works to stabilize these fluctuations, maintaining a specific voltage output despite changes in the input voltage.

Core Components of Apex Regulator PCBs

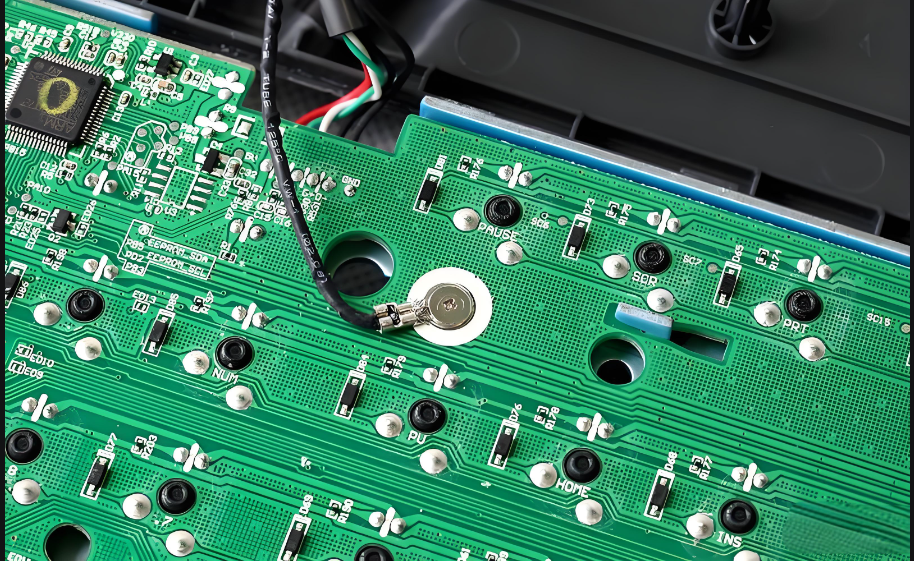

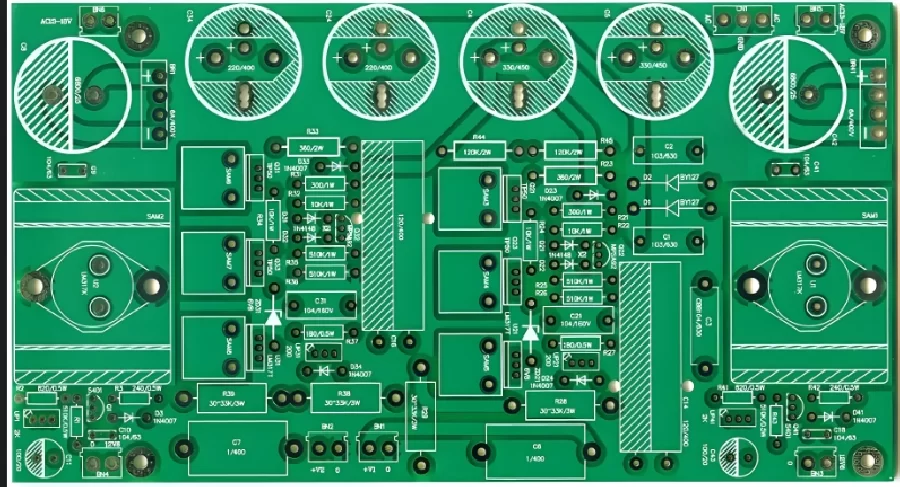

The design of an apex regulator PCB involves the integration of several components that work together to regulate the power supply. Each of these components plays a vital role in ensuring the efficiency and reliability of the voltage regulation process:

- Voltage Regulators: These are the most critical elements of an apex regulator PCB. Voltage regulators control the voltage levels within the system, either stepping down or stepping up the voltage as required. They can be classified into two main types: linear regulators and switching regulators. Linear regulators are more straightforward but less efficient, dissipating excess voltage as heat. Switching regulators, on the other hand, are more efficient and are often used in high-power systems where energy conservation is important.

- Capacitors and Resistors: Capacitors store electrical energy and release it when necessary, helping to smooth out voltage fluctuations. Resistors, meanwhile, help control the flow of current, preventing overloads and ensuring that the system operates within safe parameters.

- Thermal Management Systems: Voltage regulation can generate significant amounts of heat, especially in systems that handle large power loads. To prevent overheating, apex regulator PCBs often incorporate heat sinks or thermal vias that dissipate excess heat and keep the system within a safe operating temperature range.

- Feedback Control Systems: Feedback systems continuously monitor the output voltage and make adjustments as needed to ensure that it remains within the desired range. This helps to maintain precise control over the power supply, ensuring that any variations in input voltage are corrected before they can affect the performance of the system.

The Functioning of Apex Regulator PCBs

Understanding how an apex regulator PCB functions requires examining its role in maintaining stable voltage levels in an electronic system. The process involves several stages, each designed to ensure that the voltage supply remains consistent:

- Receiving Input Voltage: The PCB receives input voltage from a power source, which may vary due to several factors such as fluctuations in the external power grid or battery depletion in portable devices. This input voltage is typically higher or lower than the desired level for the system’s components.

- Regulating Voltage: The voltage regulator on the PCB adjusts the incoming voltage to match the required output level. For example, if the input voltage is too high, the regulator will either dissipate the excess energy as heat (in the case of linear regulators) or convert it into a usable form for later use (as in switching regulators). If the input voltage is too low, the regulator will increase it to the appropriate level.

- Stabilizing Output Voltage: Once the voltage has been regulated, the PCB distributes it to the various components of the electronic system. Feedback control systems continuously monitor the output voltage to ensure that it remains stable, making real-time adjustments as needed to counteract any fluctuations in the input voltage.

- Ensuring Longevity: By maintaining a stable voltage supply, the apex regulator PCB helps to protect sensitive components from damage caused by voltage surges or drops. This not only improves the reliability of the system but also extends the lifespan of the electronic device.

Types of Voltage Regulators Used in Apex Regulator PCBs

There are different types of voltage regulators used in apex regulator PCBs, each tailored to meet specific application needs. The choice of regulator depends on factors such as the power requirements of the system, the efficiency needed, and the size and complexity of the electronic device.

- Linear Voltage Regulators: Linear regulators are among the simplest types of voltage regulators. They work by dissipating excess voltage as heat, maintaining a steady output voltage regardless of fluctuations in the input voltage. While they are less efficient than other types of regulators, linear regulators are often used in low-power applications where efficiency is less critical and cost is a more important factor.

- Switching Voltage Regulators: Switching regulators are more efficient than linear regulators because they convert excess voltage into usable electrical energy rather than dissipating it as heat. They are commonly used in high-power applications where energy efficiency is crucial, such as in battery-powered devices or systems that operate in environments with limited power availability. Switching regulators come in various forms, including buck converters (which step down voltage) and boost converters (which step up voltage).

- Low-Dropout Regulators (LDOs): LDOs are a special type of linear regulator that can operate with very small differences between the input and output voltage. They are ideal for applications where space is limited, and low power consumption is essential, such as in portable devices like smartphones and wearables.

Applications of Apex Regulator PCBs

The wide-ranging applications of apex regulator PCBs reflect their importance in maintaining stable power supplies across various industries. Some of the most notable applications include:

- Consumer Electronics: In devices such as smartphones, tablets, and laptops, voltage regulation is critical to ensure the proper functioning of sensitive components. Apex regulator PCBs help to prevent power surges and brownouts from damaging these devices, which could lead to reduced performance or complete failure.

- Automotive Systems: Modern vehicles are equipped with a wide range of electronic systems, from engine control units to infotainment systems and sensors. Apex regulator PCBs ensure that these systems receive consistent voltage, even when the vehicle is subjected to varying driving conditions, such as rapid acceleration or braking.

- Industrial Machinery: In industrial environments, reliable power management is crucial to ensure the smooth operation of machinery and automated systems. Apex regulator PCBs help to prevent power fluctuations from causing disruptions in production processes or damaging expensive equipment.

- Medical Devices: In the medical field, precise and reliable power management is essential for the proper functioning of devices such as diagnostic equipment, monitoring systems, and life-support machines. Apex regulator PCBs help to ensure that these devices receive a stable power supply, minimizing the risk of malfunctions or failure during critical procedures.

- Telecommunications Equipment: In telecommunications, stable power is essential for ensuring uninterrupted service. Apex regulator PCBs are used in devices such as routers, switches, and base stations to maintain consistent power levels, preventing signal disruptions or communication failures.

Future Trends in Apex Regulator PCBs

The increasing demand for more efficient and compact electronic devices is driving innovation in the design and development of apex regulator PCBs. One of the key trends in this field is the move towards smaller, more energy-efficient components that can handle higher power loads without generating excessive heat. This trend is particularly important in industries such as consumer electronics and telecommunications, where devices are becoming smaller and more powerful, requiring more efficient power management solutions.

Another trend is the integration of advanced materials, such as gallium nitride (GaN), into voltage regulator designs. GaN semiconductors offer superior efficiency and thermal performance compared to traditional silicon-based components, making them ideal for use in high-power applications.

In addition, the growing focus on renewable energy and energy-efficient technologies is expected to drive further advancements in apex regulator PCB design. As more industries adopt sustainable practices, the demand for energy-efficient power management solutions will continue to grow, placing apex regulator PCBs at the forefront of this technological evolution.

Emerging Applications in Energy and AI-Powered Systems

As the world continues to embrace new technologies such as AI, automation, and the development of smart energy grids, apex regulator PCBs are being called upon to perform in increasingly dynamic environments. For instance, in AI-driven systems that require rapid data processing, the apex regulator PCB ensures stable power flow, maintaining performance levels and protecting complex systems from potential energy interruptions.

In renewable energy sectors, such as solar or wind power generation systems, the efficiency of energy conversion and distribution is key to their success. Apex regulator PCBs are at the heart of these systems, providing necessary voltage regulation to ensure that energy is efficiently managed and stored, regardless of the natural fluctu