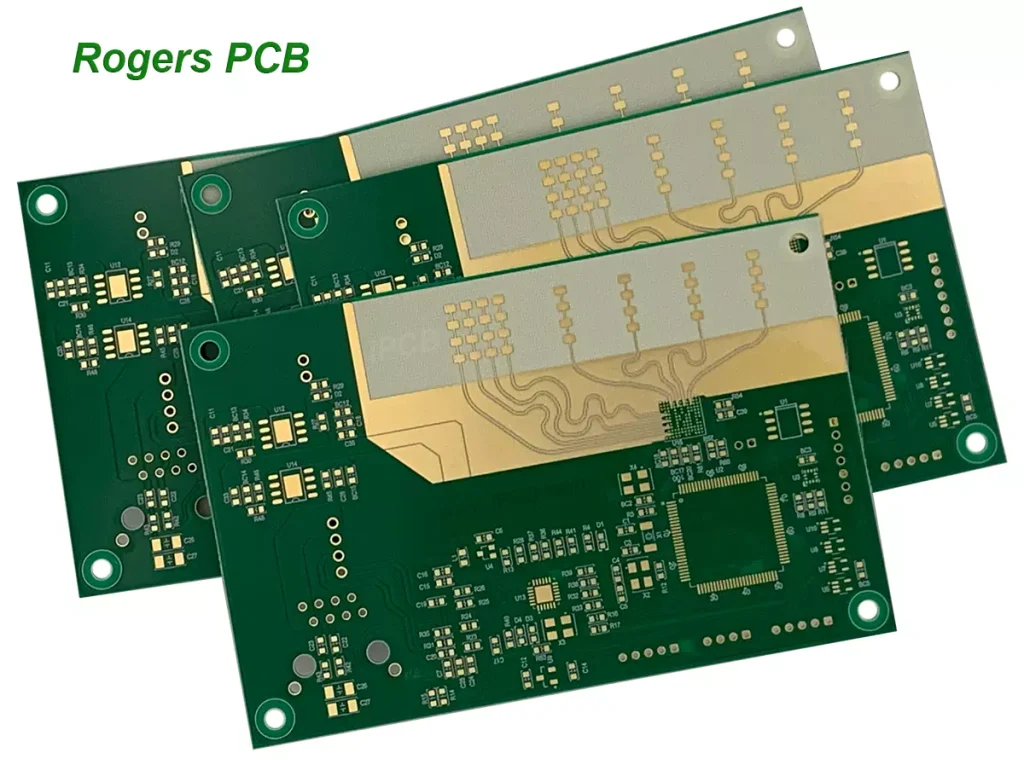

Rogers PCB is high-performance high-frequency circuit board that uses Rogers company’s unique high-frequency circuit board materials. It has excellent dielectric properties, thermal stability, and mechanical strength, and can operate reliably under harsh conditions such as high temperature, high humidity, high frequency, and high speed.

Rogers PCB has different material combinations to choose from, which may be different compositions of laminated materials composed of woven glass reinforced epoxy resin laminates, cross stacked woven glass reinforced laminates, and PTFE ceramic laminates. Thermosetting thermal conductive adhesive (TECA) films, ceramic PTFE adhesive layers, and hydrocarbons can also be used as adhesive materials.

Although Rogers circuit board materials are more expensive than other materials, they can perform best under worse conditions and have more advantages. Due to the fact that FR-4 material can provide basic standards for PCB substrates, it maintains the most effective stability between cost, durability, performance, production, and electrical performance.

Rogers Corporation was founded in 1832 and has over 60 years of professional experience as a global supplier of high-performance RF materials. Rogers is a world-class leading manufacturer of high-performance dielectrics, high-frequency laminates and semi solidified films. Its products are widely used in high reliability, wireless and wired infrastructure, automotive radar sensors, satellite TV, mobile Internet equipment, micro wave and RF printed circuits in advanced chip packaging and related applications.

Rogers Corporation is headquartered in Chandler, Arizona. It also has a strong production, sales, and technical service network in North America, Europe, and Asia, providing localized support services to global customers. Rogers’ recently expanding production capacity and expanding product range can support a wide range of applications and environmental needs.

Rogers’ application and technical service engineers are also very willing to provide assistance to customers in material selection, design, and manufacturing of printed circuit boards. With unparalleled industry expertise, Rogers continues to envision and develop new material solutions that can address greater challenges. For example, in recent years, Rogers has launched thermal management materials and is continuously committed to innovation to meet the needs of numerous new and higher power applications. Despite being a leader in the industry, Rogers is still committed to continuously exploring the potential electrical characteristics of materials, so that possible problems can be predicted, and working together with all parties to continuously improve the height of material performance.

Rogers model

TMM, AD250C, AD255C, AD300D, AD350A, AD1000, Anteo, CLTE-XT, CLTE, CLTE-AT, CLTE-MW, CuClad 217, CuClad 233, CuClad 250, DiClad 880, DiClad 870, DiClad 527, IsoClad 917, IsoClad 933, Kappa 438, MAGTREX 555, AD series, CLTE series, CUCLAD series, DICLAD series, ISOCLAD series, RO3003G2, RO3003, RO3203, RO3035, RO3006 RO3206, RO3000 series, RO3010, RO3210, RO4003C, RO4350B, RO4360G2, RO4830, RO4000 series, RO4835T,RO4835,RO4533,RO4534,RO4535,RO4725JXR,RO4730G3,RT/duroid 5880LZ,RT/duroid 5880,RT/duroid 5870,RT/duroid 6002

The characteristics of Rogers PCB

Low power signal loss

Cost effective PCB manufacturing

Low dielectric loss

Has high thermal management capabilities

The dielectric constant range is wide, and the DK value ranges from 2.55 to 10.

For space applications, low degassing capacity

Improving impedance control

The application areas of Rogers PCB board include automobiles, connecting devices, the Internet of Things, mobile internet devices, wireless infrastructure, wired infrastructure, antennas, microwave backhaul, power amplifiers, small base stations, distributed antenna systems, computing equipment, data centers, IP infrastructure, testing and measurement, antenna systems, communication systems, radar systems, aviation systems, thermal management, microwave circuits, RF printed circuits, aerospace, defense, wireless infrastructure, wired infrastructure, digital infrastructure, automotive radar sensors, satellite TV, mobile internet equipment, high-end chip level packaging, DLP company, digital projection systems, SLA 3D printing technology, 3D lithography printing technology

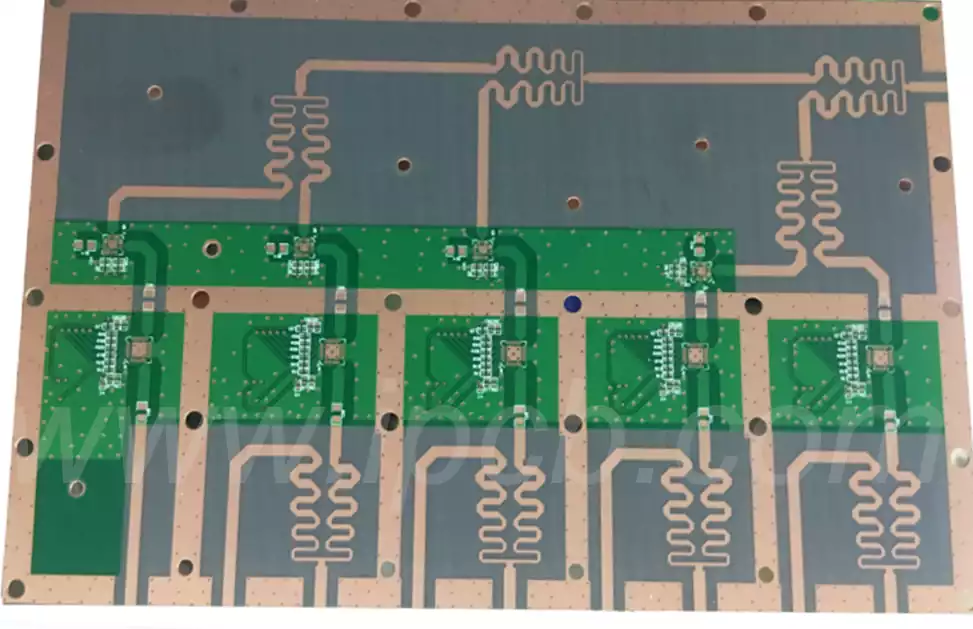

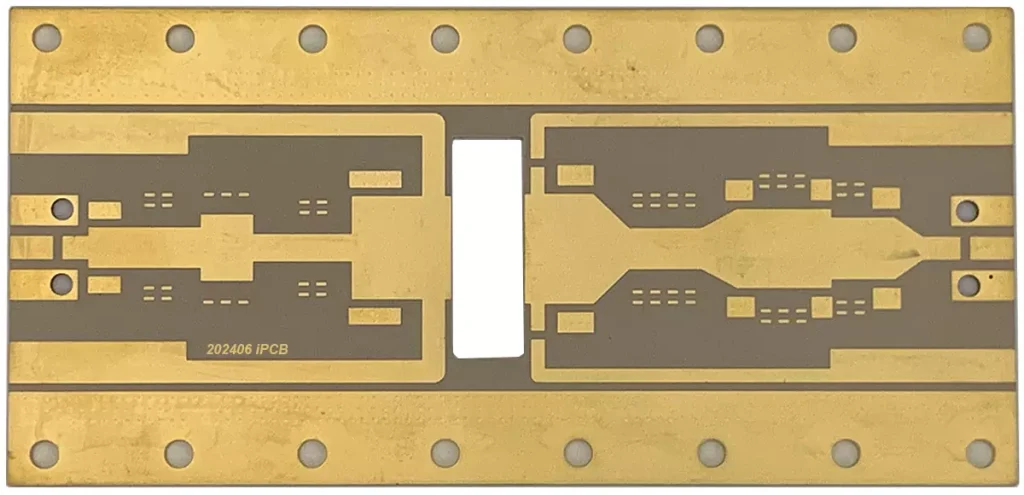

Roger PCB materials such as high-frequency materials have relatively low costs and allow for the number of frequency bands of PCB materials. Usually, it is used for radar sensor applications. It has a Rogers hybrid PCB that uses a combination of materials with multiple coating flame retardant standard FR-4 material. In addition, the glass transition temperature represented by (Tg) has a higher value. In addition, it is composed of single-layer PCB materials used for high-frequency applications.

The composition of PCB materials is necessary for maintaining reliability, controlling costs, and leading to increased electrical performance. Radar sensors require a frequency of 77 GHz to meet specific performance requirements. Therefore, for the outer layer, Roger materials are mainly used for high-frequency device design. This material has the necessary characteristics for excellent performance at millimeter wave and microwave frequencies.

In the field of electronics, the design of efficient power amplifiers is crucial. The PCB board material for high-efficiency amplifier circuits should have the necessary characteristics to ensure the high amplification performance of the design. Rogers PCB is mainly used for high-power amplification purposes. In order to achieve high performance from power amplifiers, heat must be kept away from transistors. It has better thermal expansion coefficient and thermal conductivity, which has been discussed. In addition, it will also extend the lifespan of the speaker. Thermal conductivity is defined as the power required in watts per meter of material per degree Celsius. Therefore, Rogers PCB is one of the best PCB materials in many modern applications.

Cost is the first difference to consider in this section. The ultimate goal of any PCB manufacturer is to launch high-performance and cost-effective circuit boards with the best performance. FR4 PCB is the most affordable PCB on the market. If your design is aimed at the optimal conditions with low frequency and nominal temperature settings, then this is effective. If your application requires high-speed or extreme temperature operation, you may have to ignore the cost and choose expensive Rogers PCBs.

Impedance stability is the next difference between FR4 and Rogers PCBs. The dielectric constant of a substrate is one of the important factors that define the impedance and stability of a circuit board. The higher the dielectric constant, the higher the impedance stability. Although FR4 is the cheapest available sub state, its maximum dielectric value is 4.5. The Rogers PCB has a higher and wider dielectric range, such as 6.5 to 11. This feature makes Rogers PCBs the best choice for high thermal applications where stable impedance is crucial.

In high-speed applications, PCBs generate significant heat and must be carefully handled with a good thermal management system. In this case, the thermostat based laminate in Rogers PCB is the best choice. The FR4 PCB cannot withstand high temperatures and therefore cannot be used in such applications.

The dissipation coefficient represents the signal loss in the PCB, and compared to the FR4 PCB, the signal loss in Rogers PCB is much lower. The loss factor of FR4 PCB is 0.02%, while Rogers PCB is 0.004%. Therefore, compared to FR4 PCBs, Rogers PCBs can provide reliable results with minimal electrical signal loss.

The moisture absorption is directly related to the electrical and thermal properties of the substrate material. This in turn will affect the performance of the circuit board. Rogers PCB has the least moisture absorption, therefore it can provide the best efficiency under various environmental conditions.

The application and performance are based on overall performance, with FR4 PCB being considered a good participant, while Rogers PCB performing exceptionally well. Therefore, FR4 PCB is the most suitable environment for medium to low frequency applications. They are sturdy and durable, with excellent balance in electrical stability, and can be easily manufactured in almost all existing processes in the PCB industry. And Roger PCB is suitable for advanced performance in niche fields such as space applications. The constant temperature and low gas release characteristics make it the best choice for key applications such as space and aerodynamics.

Which industries need to choose Rogers PCB?

1. Automotive radar

With the development of science and technology, the automotive manufacturing industry has already laid out corresponding line equipment on production lines, with the aim of helping optimize the manufacturing process more quickly. The specific focus of circuit board application lies in the development and construction of radar. By drawing and polishing corresponding wire diagrams, the construction foundation of radar equipment is made more solid.

2. Power amplifier

Power amplifiers are a type of safety protection tool that various industry equipment must use when carrying out high load operations at a certain stage. The corresponding Rogers circuit board can be directly embedded in such devices, making the thermal insulation performance and ensuring the effectiveness of the devices more perfect, and ensuring that the heat resistance performance of the circuit board itself is trusted by more application links.

3. Live broadcast satellite

Live broadcasting satellites do not belong to the corresponding commercial operation scope, but are more in line with the development of space affairs. Therefore, the application of such circuit boards in the construction of live broadcast satellites proves that the board has a higher level of utilization. Capable of enabling personnel involved in satellite research and development to independently analyze circuit boards and clarify the relationship between conductivity maps and high-frequency materials.

Rogers high-frequency PCB is a stable material with low dielectric loss, low water absorption, and stable dielectric constant (DK) with frequency variation. It has low exhaust rate in aerospace applications and is widely used in high reliability, aerospace, defense applications, or harsh environmental applications.

Rogers high-frequency circuit board have become a key factor driving the development of electronic communication technology. Its unique performance not only meets current technological needs, but also lays the foundation for future technological innovation. With the continuous exploration and optimization of high-frequency signal transmission materials, Rogers PCB board will continue to play an indispensable role in the field of electronic communication.

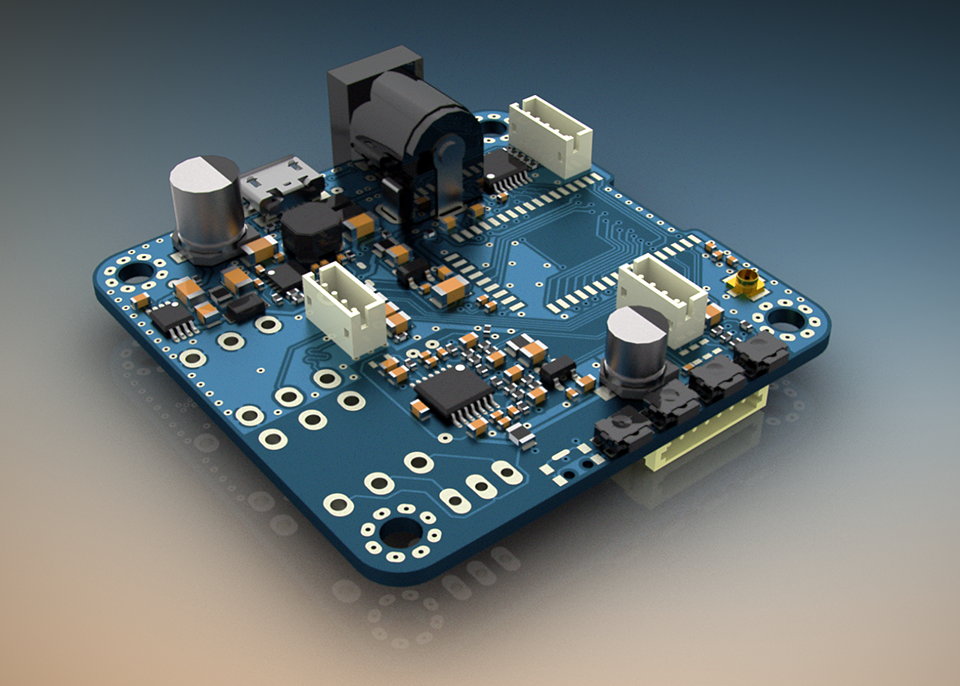

iPCB Company specializes in producing high-precision, high-density, special materials, and special process PCB circuit board. The products mainly include high-frequency PCB, Rogers PCB, Taconic PCB, F4B/PTFE high-frequency circuit board, microwave RF circuit board, special circuit board, etc. Choosing iPCB will be a wise choice for you to pursue high-quality and efficient services.