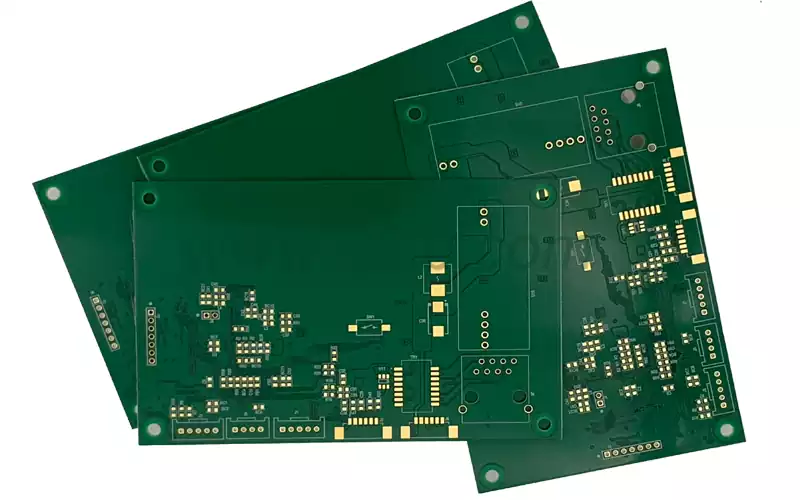

Immersion gold technology is a process that deposits a thin layer of gold on the surface of copper through a chemical reaction. In the manufacturing process of printed circuit boards, the electrical conductivity and corrosion resistance of gold provide a key guarantee for the performance of the board. Simply put, it is the use of chemical deposition methods, through the chemical redox reaction on the circuit board surface to produce a layer of metal plating.

The process of immersion gold mainly includes the following steps:

Pre-treatment: Clean and pre-treat the surface of the copper board to remove oil and oxides and ensure a smooth and even surface.

Micro-etching: Use micro-etching solution to micro-etch the surface of the copper plate to increase the roughness of the surface, in order to improve the adhesion.

Activation: A palladium layer is formed on the surface of the copper plate through a chemical reaction, which acts as a catalyst for gold immersion.

Deposited gold: the copper plate is immersed in a solution containing gold salts, and a gold layer is deposited on the copper plate through a chemical reaction.

Post-processing: Cleaning and drying of the copper board, necessary inspections and tests to ensure that the quality is up to standard.

The benefits of using immersion gold pcb

1. The color is bright, good color, good appearance, and enhances the attractiveness of the customer.

2. The crystal structure formed by immersion gold is easier to weld than other surface treatments, which can have better performance and ensure quality.

3. Because the immersed gold plate only in the pad with nickel gold, will not have an impact on the signal, because the skin effect in the signal transmission is in the copper layer.

4. The metal properties of gold are more stable, the crystal structure is more dense, not easy to oxidation reaction.

5. Because the immersed gold plate only pads on the nickel gold, so the line solder resistance and the combination of the copper layer is more solid, and is not easy to cause a micro-short circuit.

6. The project will not have an impact on the pitch when making compensation, facilitating the work.

7. Immersed gold plate stress is easier to control, in the use of better experience.

The difference between gold immersion and gold plating:

Sinking gold using the chemical deposition method, through the chemical redox reaction method to generate a layer of plating, the general thickness is thicker, is a chemical nickel gold layer deposition method, you can achieve a thicker layer of gold.

Gold plating uses the principle of electrolysis, also called the electroplating method. Most of the other metal surface treatment is also used is the electroplating method.

In the actual product application, 90% of the gold plate is immersed gold plate, because the poor weldability of the gold-plated plate is its fatal flaw, but also lead to many companies giving up the gold-plated process is the direct cause!

Sinking gold process in the printed circuit surface deposition of color stability, good brightness, flat plating, and good solderability of nickel-gold plating. Can be basically divided into four stages: pre-treatment (degreasing, micro-etching, activation, after dipping), immersion nickel, immersion gold, and post-treatment (waste gold washing, DI washing, drying). The thickness of gold immersion is between 0.025-0.1um.

Gold is used in printed circuit board surface treatment, because of the strong conductivity of gold, good oxidation resistance, long life, and general applications such as a keypad, gold fingerboards, etc., and gold-plated and gold-immersed board is the most fundamental difference between the gold-plated board, gold-plated is a hard gold (wear-resistant), gold-immersed is a soft gold (not wear-resistant).

1. Immersion gold and gold plating formed by the crystal structure are not the same, immersion gold for the thickness of the gold is much thicker than gold plating, immersion gold will be golden yellow, more yellow than gold plating (this is one of the ways to distinguish between gold plating and immersion gold), gold plating will be slightly whitish (the color of nickel).

2. Immersed gold and gold plating formed by the crystal structure is not the same, immersed gold relative to gold plating is easier to weld, and will not cause bad welding. Immersion gold plate stress is easier to control, for products with bonding, and more conducive to the processing of bonding. At the same time is also because the immersed gold is softer than gold-plated, so the immersed gold plate to do the gold finger is not wear-resistant.

3. The immersed gold plate only pads on the nickel gold, the skin affects in the signal transmission in the copper layer and will not have an impact on the signal.

4. Immersed gold is denser than gold-plated crystal structure, not easy to produce oxidation.

5. With the circuit board processing accuracy requirements are becoming more and more high, and line width and spacing have reached below 0.1mm. Gold plating is prone to short-circuit gold wire. Immersion gold plate only pads on the nickel gold, so it is not easy to produce gold short circuit.

6. Not only pads on the nickel gold, so the line of solder resistors and the combination of the copper layer is more solid. Engineering in the compensation will not have an impact on the pitch.

7. For the higher requirements of the board, flatness requirements to be good, generally use immersed gold, immersed gold generally does not appear after the assembly of the black pad phenomenon. The flatness and service life of the pcb board is better than the gold-plated board.

Immersion gold in the manufacture of printed circuit boards shows significant advantages and a wide range of application prospects. Through the reasonable use of the process, you can improve the conductivity, corrosion resistance, and reliability of printed circuit boards to meet a variety of demanding applications.