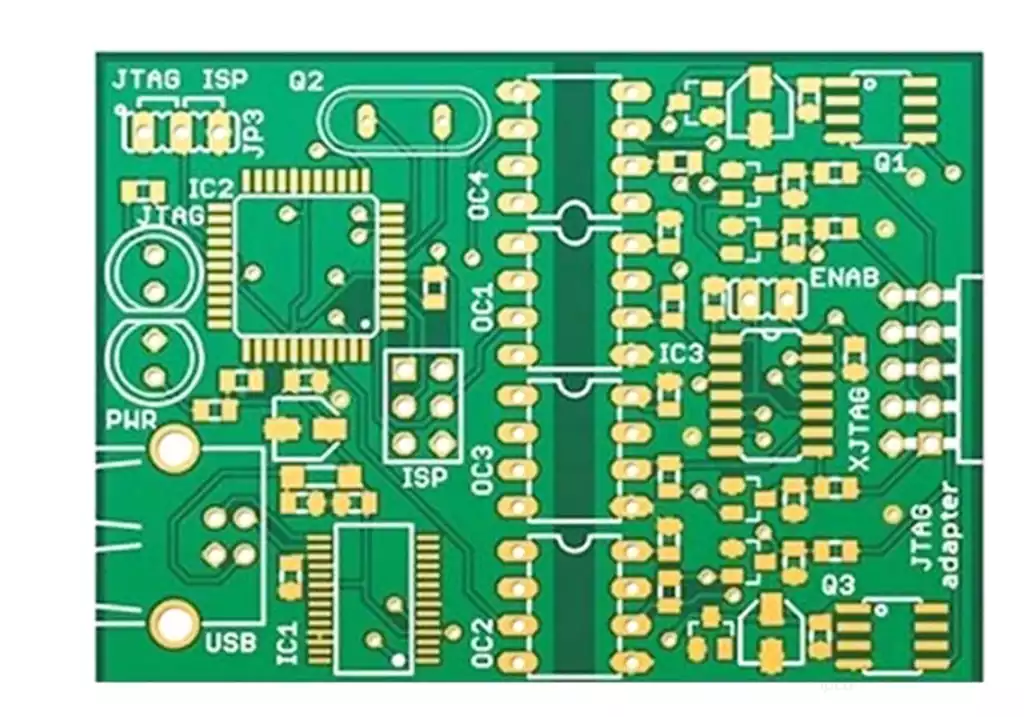

CTI FR4 is a measure of the electrical breakdown performance of dielectric materials used in printed circuit boards, where CTI is a measure of the electrical breakdown performance of dielectric materials and FR4 is a common insulating material.

CTI, Comparative Tracking Index, is a measure of the electrical breakdown performance of dielectric materials used in PCBs. the higher the CTI value, the better the material’s resistance to arc tracking, i.e., the less likely the material will form a conductive channel under the action of an arc. In PCB design and manufacturing, CTI value is an important parameter, which directly affects the electrical performance and reliability of the PCB.

FR4 is a commonly used insulating material, mainly used in the manufacture of PCB substrates. It is a glass fiber-reinforced epoxy resin sheet with good electrical, mechanical and processing properties, and the “FR” in the name of FR4 stands for “Flame Retardant”, which means that the material has a certain degree of flame retardant properties.

IEC950 has three levels of CTI: Class I (CTI≥600V), Class II (600V>CTI≥400V), and Class III (400V>CTI≥175V) CTI values are differentiated according to the level, and the smaller the level, the higher the resistance to leakage traces.

CTI The chemical properties of FR4 are mainly related to its constituent materials.FR4 is an epoxy resin sheet reinforced by glass fibers, so its chemical properties are largely influenced by epoxy resin.

Epoxy resin is a polymer compound with good chemical stability. It has high chemical resistance and is able to resist many common chemicals such as acids, alkalis and salts. This allows CTI FR4 materials to maintain their performance and stability under harsh environmental conditions.

CTI FR4 also has flame retardant properties due to the epoxy resin containing certain flame retardants. These flame retardants are able to form a barrier layer when the material is subjected to high temperatures or flames, preventing the spread of flames and thus improving the material’s flame-retardant properties.

Although it has good chemical stability, its performance may be affected under certain specific conditions, such as high temperatures, strong acids and alkalis, and other extreme environments. Therefore, when using CTI FR4 material, it is necessary to fully consider the environment and conditions of its use to ensure its performance and reliability.

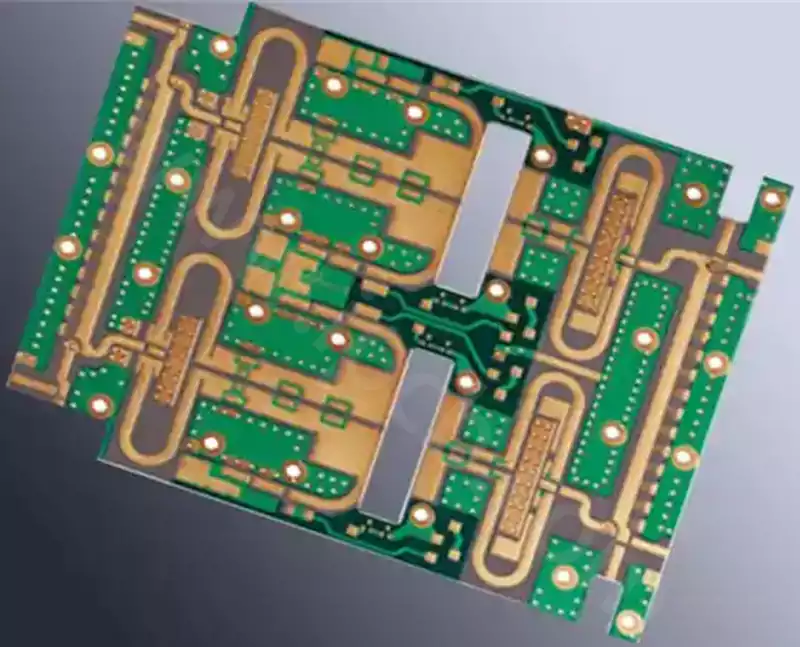

As an important material in PCB manufacturing, CTI FR4 has become a star material in the industry for its excellent electrical performance and reliability. Its wide application not only promotes the rapid development of the electronics industry, but also brings more convenience and possibilities to our life.