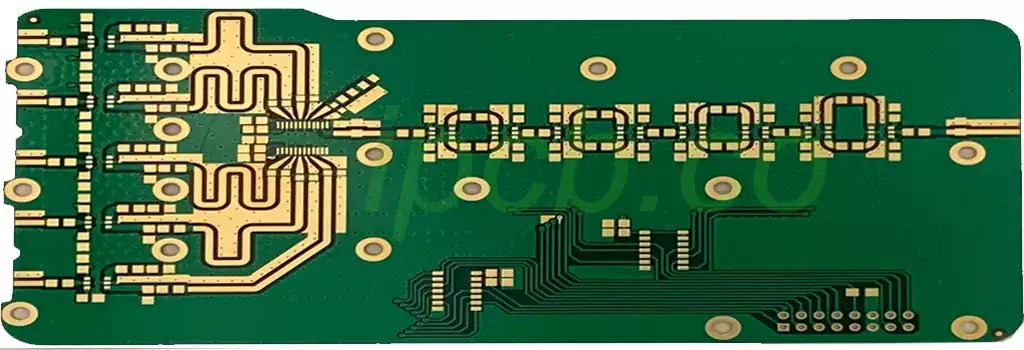

PTFE PCB refers to printed circuit boards made with polytetrafluoroethylene (PTFE) material.PTFE, known as polytetrafluoroethylene, is a high-performance fluoroplastic. It has excellent insulating properties, high-temperature stability, good chemical stability, and a very low coefficient of friction, so it is widely used in a variety of industrial fields. In PCB manufacturing, PTFE is mainly used as an insulating layer and cover layer material.

PTFE PCB has the advantages of chemical resistance, outstanding high-frequency performance, high stability and reliability, and ease of processing. These characteristics make it a very valuable circuit board material, in the electronics and communications industry and industrial production in a wide range of applications:

1.Excellent chemical resistance

PTFE has excellent chemical resistance and is resistant to most chemicals. This is due to the strong carbon-fluorine bond in its molecular chain, which keeps it stable in extreme acid and alkali environments. As a result, PTFE PCBs are not only suitable for extremely acidic and alkaline corrosive working environments, but also maintain their performance at high temperatures and high pressures, making them popular in the fields of aviation, aerospace and marine engineering.

2.Outstanding high frequency performance

PTFE insulating material has a low dielectric constant (dielectric constant range of 2.1-2.3) and low dielectric loss, so that PTFE PCB in high-frequency signal transmission has superiority. It can stably transmit high-speed signals and power, reducing signal loss and distortion.

3.High stability and reliability

It has extremely high stability and reliability. It is able to withstand extreme temperature, humidity and other factors of damage, in a long time of repeated use or even overuse can still maintain the performance and effect. This superior durability makes it widely used in industry, medicine and aerospace, etc., which require very high stability performance of electronic equipment.

4.Easy processing

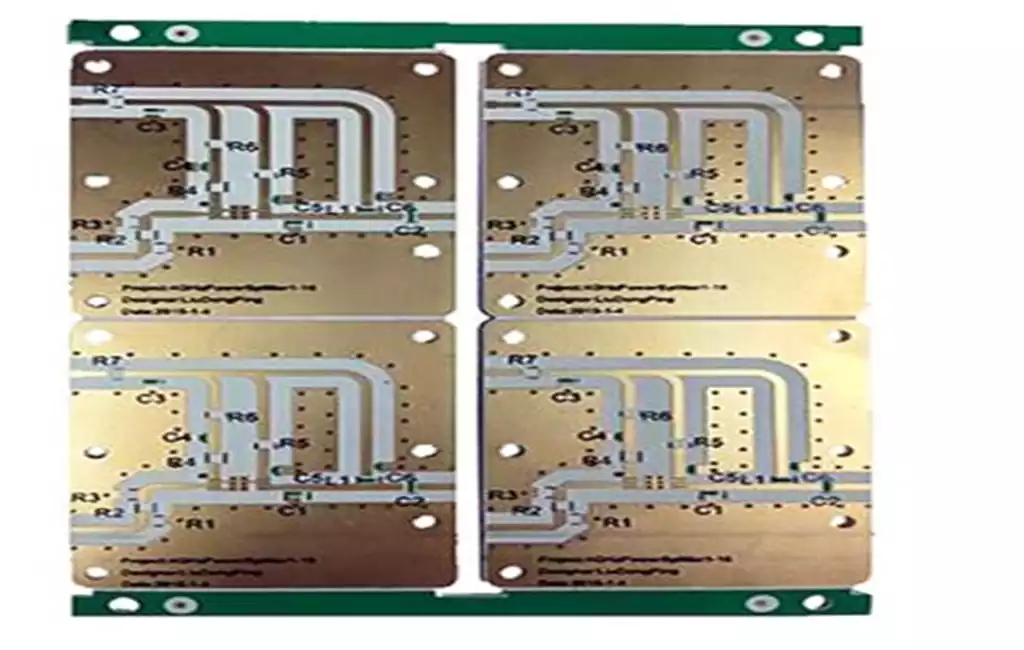

PTFE PCB has a small density and high flatness, suitable for special high-difficulty PCB processing, such as blind buried holes, multilayer boards, thin boards. At present, the production of PTFE sheet has been very common, and its application in the circuit board industry is becoming more and more widespread.

Due to the special physical and chemical properties of this material, the production requires special attention to some process requirements:.

Material selection: PTFE material has various types and specifications, and the selection should be based on the specific needs of PCB and application scenarios. For example, factors such as dielectric constant, dielectric loss, temperature resistance range, etc. should be considered.

Lamination control: The lamination process of the pcb requires strict control of temperature, pressure and time to ensure tight bonding between layers and avoid bubbles or delamination.

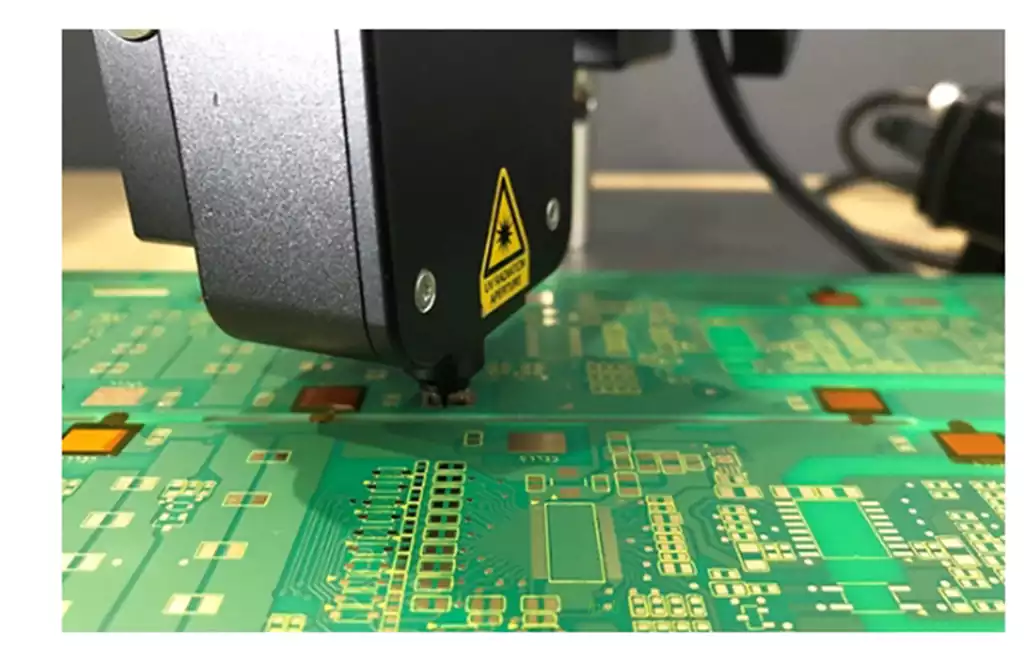

Drilling and Cutting: Due to the high hardness and abrasion resistance of PTFE, suitable tools and process parameters need to be selected for drilling and cutting to avoid excessive tool wear or burrs.

Surface treatment: According to the need, the surface of PTFE PCB is treated, such as chemical etching, plasma treatment, etc., in order to improve its wettability and adhesion, and prepare for the subsequent processes.

Electrical test: After completing the PCB fabrication, strict electrical performance tests should be conducted, including insulation resistance, voltage withstand test, etc., to ensure that the PCB meets the design requirements.

PTFE PCB is a kind of printed circuit board made with PTFE material, which has excellent heat resistance, chemical resistance and electrical performance, and is suitable for high-frequency electronic equipment. With the continuous development of electronic technology, it will be more and more widely used in the electronic and communication industry and industrial production.