Surface mount PCB board, as the name suggests, is a technology where electronic components are mounted directly onto the surface of a PCB (Printed Circuit Board). Compared with traditional plug-in components, surface mount components have the advantages of small size, light weight and high reliability. This makes surface mount PCBs play a key role in the miniaturization, lightweighting and high reliability of electronic products.

Features of mounting technology.

The object of mounting – surface mount components

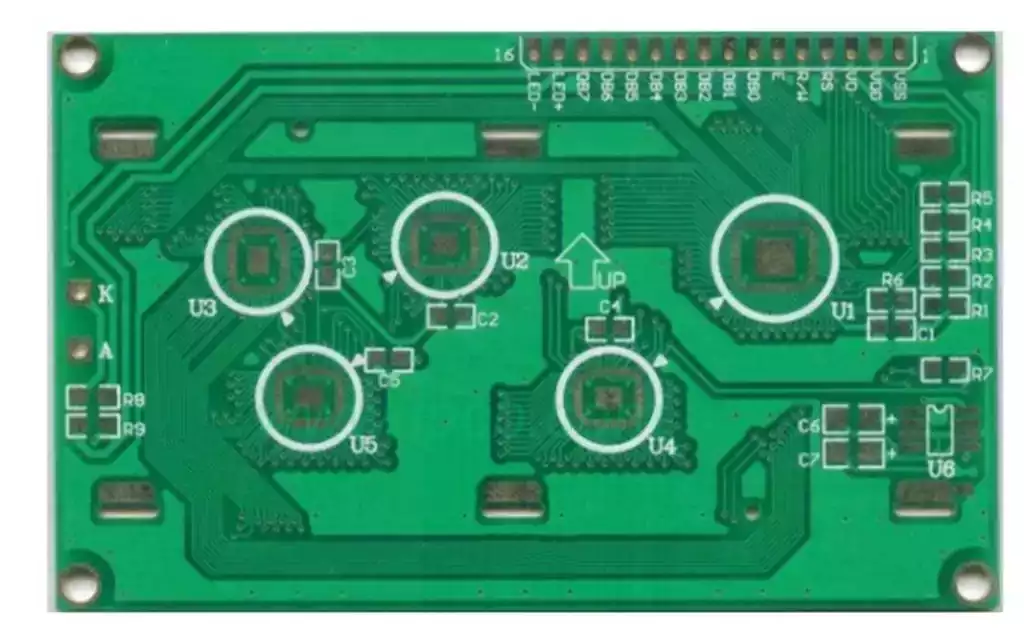

① the types of surface mount components: almost covers all of the traditional electronic components. Figure 1.9 shows only part of it.

② The volume of surface mount components: chip components, for example, commonly used chip resistors from 6.14mm3 (3216) to 0.0096mm3 (0402), a difference of about 640 times. If compared with different types, for example, surface mount transformers or connectors, the difference is thousands of times.

③ The top surface material of surface mount components: ceramics, metal and various plastics and other materials with different surface flatness and finish.

Mounting speed

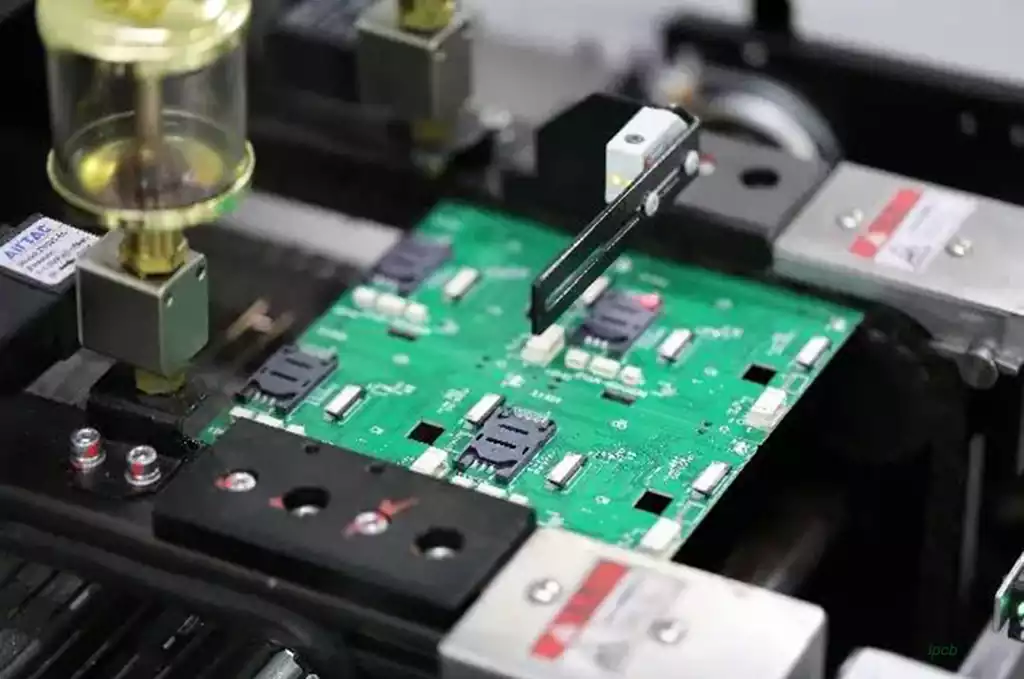

As a circuit board on the less a few kinds, dozens of components, more dozens or hundreds of hundreds to thousands of components, and these components can only be mounted one by one, so in order to improve efficiency, each component mounting time has been shortened to 0.06 s or so (chip components), has almost reached the limit of the speed of the movement of the mechanical structure.

Mounting Accuracy

Due to the increasing assembly density and the use of 0.3/0.4 pitch ICs and 0402 components, the requirements for placement accuracy are becoming higher and higher. The use of machine, light, electricity and hardware and software integrated technology, so that the mounting accuracy can now be achieved under 3 Sigma 75 μm accuracy, a part of the small components and fine pitch IC mounting accuracy is even required to 4 Sigma under 50 μm or higher. Components and components, components and devices between the distance of 0.1mm order of magnitude, meaning that the SMT placement accuracy indicators have been with the packaging technology requirements on a level.

Mounting carrier circuit board

Carrying the mounting components of the circuit board and mounting technology is mainly related to the geometry and board thickness direction of the stiffness. The board area can vary from a minimum of less than 1 cm2 to a maximum of more than 4,000 cm2, while the thickness dimension, which determines the stiffness in the direction of the board thickness, varies from less than 0.5 mm to more than 6 mm (rigid boards).

Due to the SMT mounting technology, from the surface mount components to carry the board type, geometry and the impact of the mounting of many parameters, the mounting accuracy has reached the nanometer order of magnitude, while the mounting speed is close to the limit of mechanical operation, and thus the mounting technology on the equipment requirements are very high. It is no exaggeration to say that the mounting technology is the key to surface assembly technology, and as a surface mounting equipment mounter, the decisive role in the mounting technology is incomparable to other technologies.

Surface Mount Device (SMD) is an electronic component that can be welded directly to the surface of a printed circuit board. Relative to the traditional plug-in components, surface mount components have the advantages of small size, light weight, high reliability and so on.

Second, the classification of surface mount components

Surface mount components in accordance with its shape and packaging methods, can be divided into the following categories:

- Chip components (Chip, referred to as C): the size is generally 2mm long, 1.25mm wide, the thickness from 0.25mm to 1.5mm, common resistors, capacitors, inductors and so on;

- Four-port SMD components (Quad Flat No-leads, QFN for short): commonly used in integrated circuits, varying in size, with low inductance and low resistance;

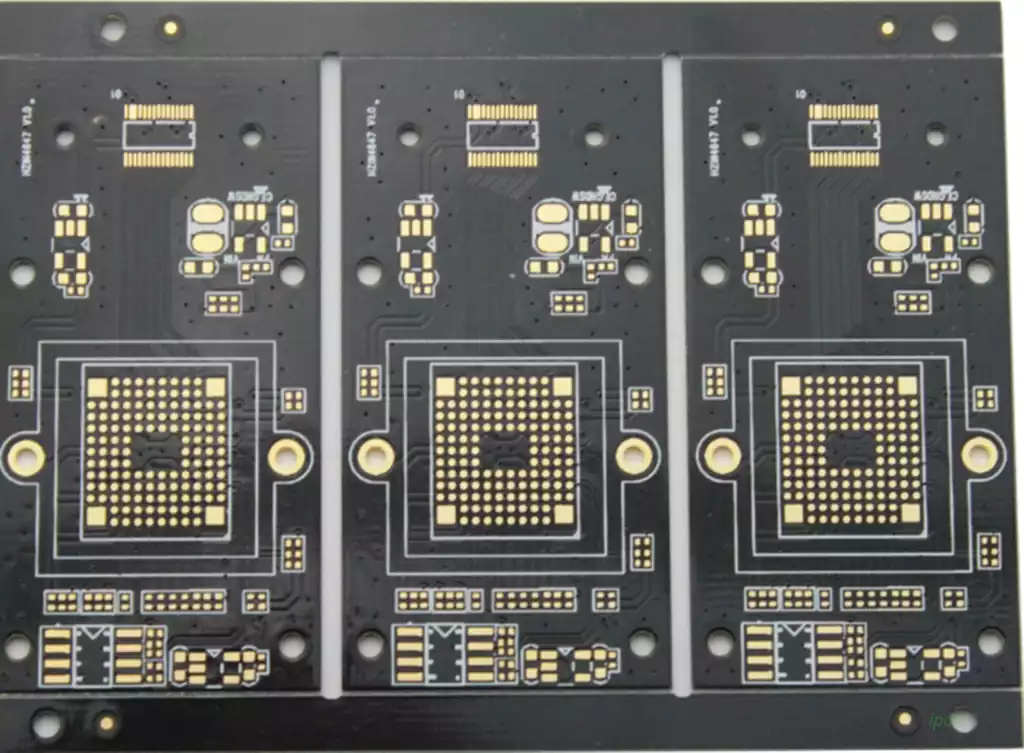

- Ball Grid Array components (Ball Grid Array, referred to as BGA): the package is smaller than the QFN, there are many solder balls distributed underneath it, for high-density circuit board design;

- Packaged transistor (Transistor Outline, TO for short): still transistors fixed to the PCB by mounting, but its processing and packaging process is different from the traditional transistor;

- Two-lead molded transistor (Small Outline Transistor, SOT for short): is a small transistor, also rely on the mounting method fixed to the PCB.

As the cornerstone of modern electronics manufacturing, the importance of surface mount PCB board is self-evident. With the continuous progress of science and technology and the continuous expansion of application areas, it is believed that surface mount PCB board will play a more important role in the future, injecting new vitality into the development of the field of pcb manufacturing.