In the electronics manufacturing industry, Through Hole vs SMD (Surface Mount Device) are two commonly used ways of mounting circuit board components, which play an indispensable role in the design and manufacturing of electronic products. Although they have their own characteristics and advantages, in many cases they are complementary, and together they contribute to the performance improvement and cost optimization of electronic products.

The choice between retaining through-hole assemblies or opting for new surface-mounted assemblies (SMDs for short) will have a direct impact on the board’s performance, cost, productivity and reliability. Here are some suggestions on how to choose based on your needs.

- Cost Considerations

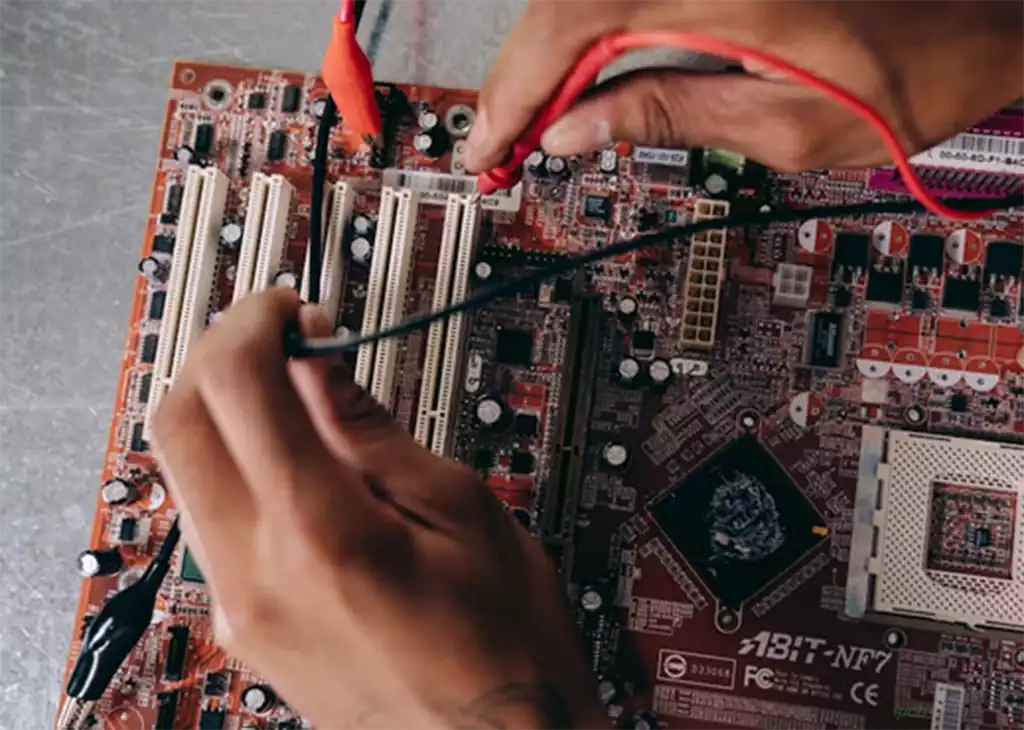

Through-hole assemblies: Through-hole assemblies are usually more expensive because of the relatively complex manufacturing process and the additional assembly steps required, such as jacking and soldering.

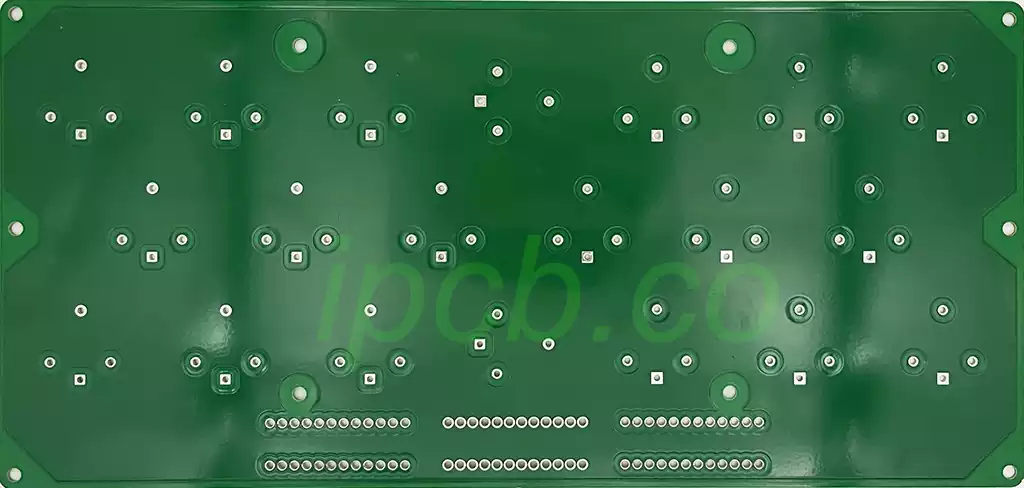

SMD assemblies: SMD assemblies are produced with a high degree of automation and are therefore relatively low cost. In addition, the smaller size saves circuit board space, further reducing costs. - Production efficiency

Through-hole assemblies: Through-hole assemblies require manual or automatic jacking and then soldering, which increases production time and cost.

SMD components: SMD components can be quickly and accurately placed on the PCB by an automatic placement machine, followed by wave or reflow soldering, which greatly improves production efficiency.

3.Reliability

Through-hole assemblies: The pins of through-hole assemblies pass through the PCB substrate and form a mechanical connection with the board through soldering, resulting in relatively high reliability and stability;

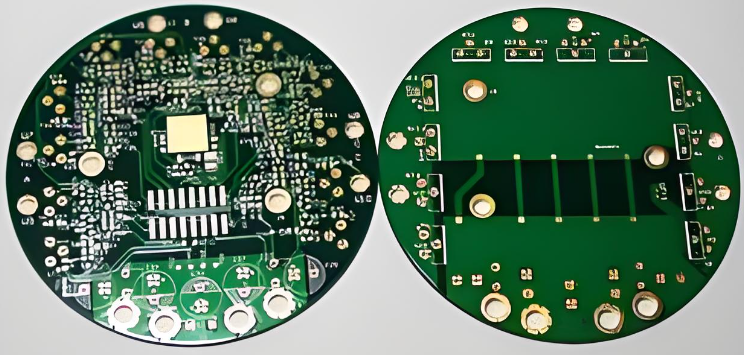

SMD components: Although SMD components have good reliability in most cases, there may be potential risks in certain high vibration or high shock environments because they are only soldered to the PCB surface.

- Design Flexibility

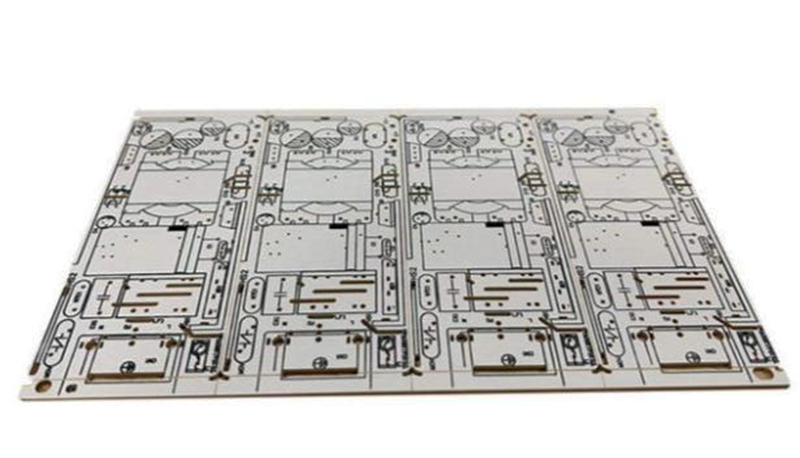

Through-hole assemblies: Through-hole assemblies have longer pins and can be easily connected to multi-layer PCBs, making them suitable for complex multi-layer designs.

SMD assemblies: SMD assemblies are suitable for single or double-layer PCB designs, as well as applications that require a high degree of integration and compact layout.

5.Application Scenarios

Through-hole components: Suitable for high reliability, high power handling or scenes subject to high vibration and shock, such as industrial control, automotive electronics and other fields.

SMD components: suitable for consumer electronics, communication equipment, computer hardware and other applications that require low cost, high productivity and good reliability.

Through-hole and SMD, as two important mounting methods for circuit board components, are complementary and jointly promote the development of the electronics manufacturing industry, although there are differences in technical characteristics and application areas.