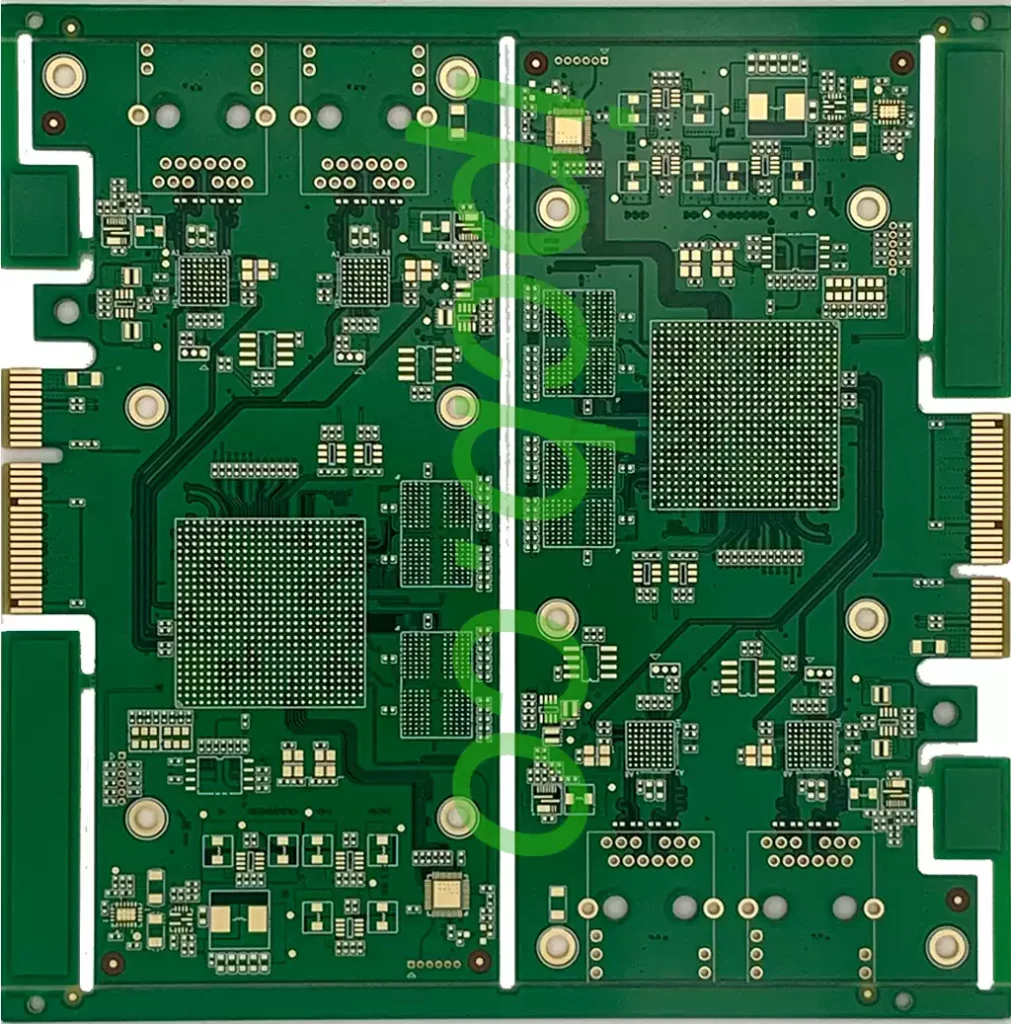

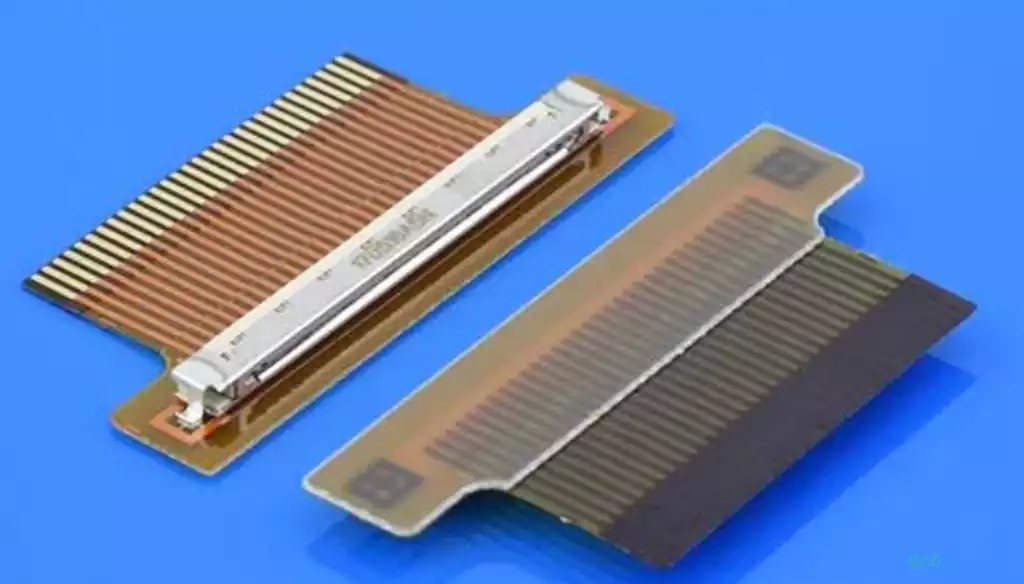

FFC connectors are used to mate ribbon flat flexible cables (FFC) to PCB circuits in wire-to-board applications. They are also available in cable-to-cable configurations. These connectors have a high density, very narrow form factor and fit into tight spaces. They are typically used in consumer applications such as laptops, cameras, computer peripherals, appliances, and telephones. Single or dual row connector housings are typically made of flexible plastics, polymers, engineered rubbers, or films that surround embedded metal connectors. A variety of locking styles are available.

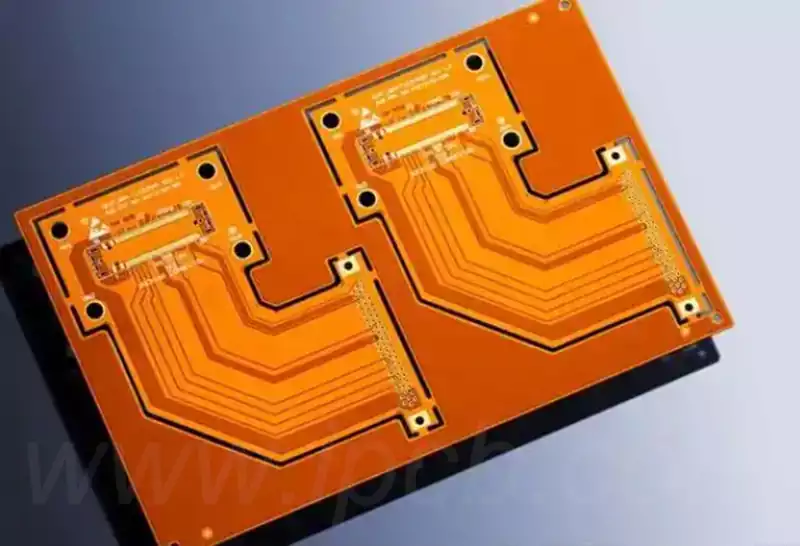

FPC connectors connect flexible printed cable (FPC) to a circuit board.FPC is a type of FFC in which the conductors are printed on the cable substrate rather than embedded in it.FPC/FFC connectors are sometimes called ribbon connectors.

Difference between FFC vs FPC connector

FFC connector is flexible flat cable connector, FPC connector is flexible printed circuit, from their two kinds of connector manufacturing above, they line formation is different:

FFC is a flat copper foil sandwiched between the top and bottom two layers of insulating foil, the finished product is simpler, thicker.

FPC is a chemical etching way to FCCL (Flexible Copper Clad Laminate) processing to get the line away from different single-sided and double-sided as well as multi-layer structure of the flexible circuit board.

In terms of price, naturally FFC connector is much cheaper, if you consider the production cost, more companies will like to use FFC connector related design.

Similarities

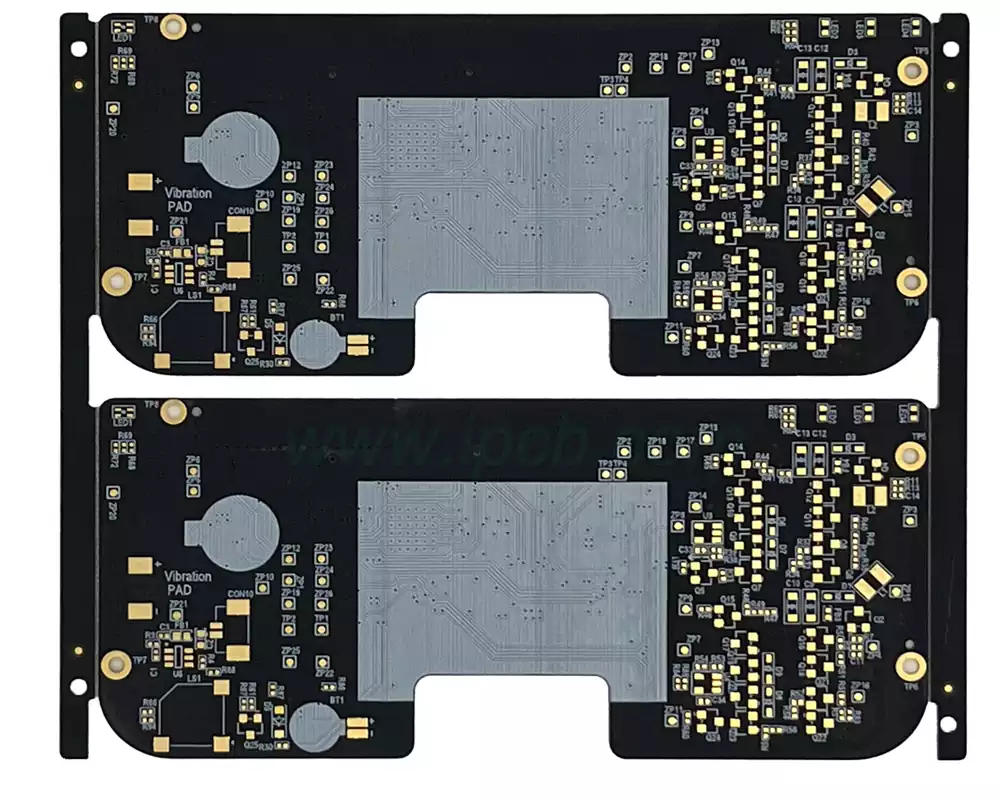

The application areas are the same. both FFC connector and FPC connector are widely used in LCD, scanner, plotter, scanner, copier, audio . Fax machine and other electronic equipment.

FFC connectors and FPC connectors have excellent flexibility, application flexibility, foldable, manufacturing miniaturization, compact, high density integration, space saving, simple wiring and other characteristics features.

FFC connector 7 common types

Type A: Both ends are connected and the reinforcement plate is pasted on the insulating tape.

Type B: Reinforcement plates are cross-linked and directly pasted on insulating tape.

Type C: Reinforcement plates at both ends are attached directly to the conductor; Type D: Reinforcement plates at both ends are attached directly to the conductor.

Type D: Reinforcement plates at both ends are cross-pasted directly on the conductor; Type E: Reinforcement plates at one end are cross-pasted directly on the conductor.

Type E: one end of the reinforcement plate is attached to the insulating tape, and the other end is directly soldered; Type F: both ends of the reinforcement plate are directly attached to the conductor.

Type F: both ends of the reinforcement plate directly on the insulating tape, the internal half peeled;

G type: both ends are directly soldered.

FFC vs FPC connector both play a vital role in the field of electronic equipment. Although they differ in manufacturing methods and costs, there are many similarities in application areas and characteristics. They both play an important role in promoting the miniaturization, miniaturization and integration of electronic equipment.