Fix pcb board is a critical part of ensuring the proper functioning of electronic equipment. Once the circuit board failure, may lead to equipment performance degradation, abnormal function or even unusable. Timely and accurate repair can restore the normal function of the circuit board, improve the stability and reliability of the equipment, and extend its service life.

Circuit board repair methods

- Troubleshooting

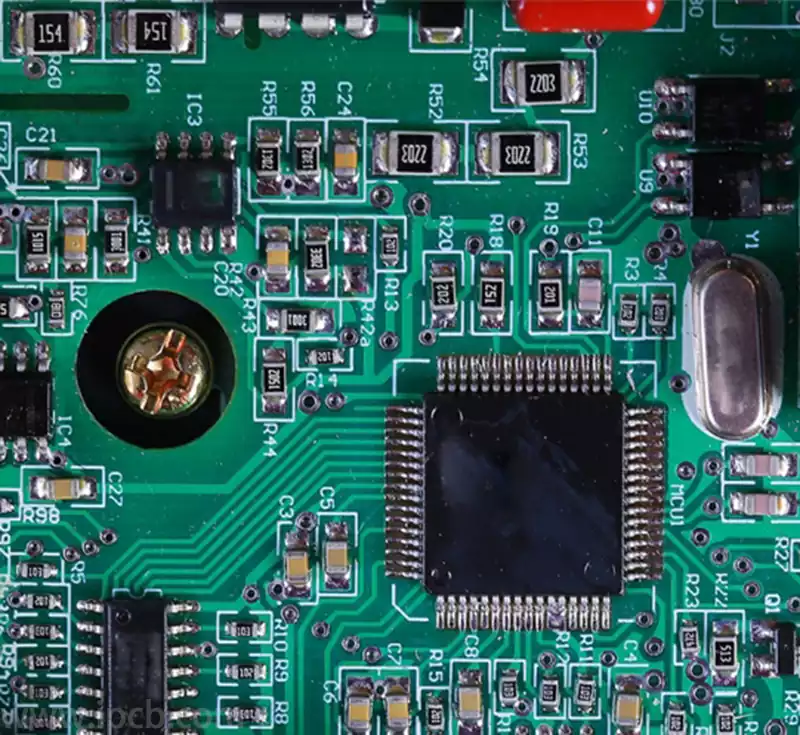

Observe the surface: Check the surface of the circuit board,observe whether there are cracked solder joints, components, oil leakage, PCB board burns and so on.

Sniffing: Sometimes faulty circuit boards may have a special odor, you can sniff to determine whether there is a burned circuit or leakage and so on.

Thermal imaging: the use of infrared thermal imager to scan the surface of the circuit board to identify abnormal hot spots, for rapid localization of the problem area - Fault location

Step-by-step method: According to the structure of the circuit board and circuit principles, the use of step-by-step method to determine the location of the fault occurred.

Regional heat retreat method: use the soldering iron on the circuit board heated in turn, by observing which area of the heat retreat speed to determine whether there is a problem. - Component testing and replacement

Test tools: the use of multimeters, logic analyzers and other test tools to detect the working state of each component on the circuit board to determine whether the component is damaged.

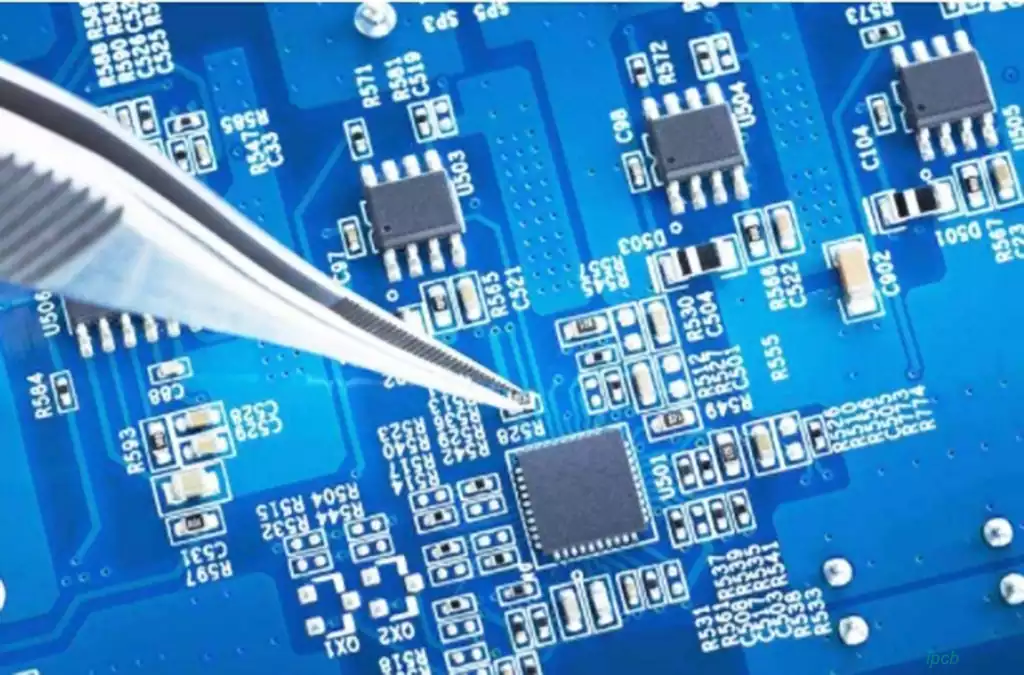

Disassembly and replacement: For damaged components, use the appropriate tools to disassemble and replace with new pcb components. - Soldering Repair

Superb soldering: Use the right amount of solder, the appropriate soldering temperature, to carry out superb soldering operations to ensure that the solder joints are strong.

Repair pads: For damaged pads, use repair agent to repair or re-solder. - Line Repair

Broken line re-soldering: When the line is found to be broken, it can be connected using wires, and pay attention to the correct position and fixing method.

Conductive paint repair: the use of conductive paint to repair the line open or short-circuit problems. - Static protection

Anti-static pads: In the repair of circuit boards, the use of anti-static pads and gloves and other anti-static equipment to avoid static electricity on the circuit board components damage. - Test verification

Function test: Repair the circuit board, the use of oscilloscopes, signal generators and other test instruments to verify the function of the circuit board for a comprehensive test.

Load test: After the circuit board is connected to normal, load test to ensure that it can be normal output under normal operating conditions.

Precautions for circuit board repair

(1) safety first: when carrying out circuit board repair, be sure to disconnect the power supply to avoid electric shock and other safety risks.

2) Repair tools: Prepare the necessary repair tools, such as soldering tools, test instruments, magnifying glasses, etc., in order to carry out delicate repair operations.

3) Technical knowledge: Circuit board repair requires certain technical knowledge and experience. If you are not familiar with circuit board repair, it is recommended to seek professional help to avoid further damage to the equipment.

4) Anti-static: When handling circuit boards, care should be taken to prevent the generation and release of static electricity to avoid damage to sensitive electronic components.

Fix pcb board, as an important part of the maintenance of electronic equipment, not only requires fine operating skills, but also focus on safety precautions. In the repair process, we must always keep in mind the principle of safety first, to ensure that the premise of disconnecting the power supply to operate, to prevent electric shock and other potential risks. At the same time, with the help of professional maintenance tools and technical knowledge, we can accurately troubleshoot and locate the problem, and carry out effective component testing and replacement, welding repair and wiring repair. However, the success of the repair work is not overnight, it requires us to accumulate experience and improve our repair skills to ensure the stable operation of the circuit boards and the long-lasting durability of the equipment. After each repair, we should also carry out comprehensive testing and verification to ensure that the repair results are optimized.