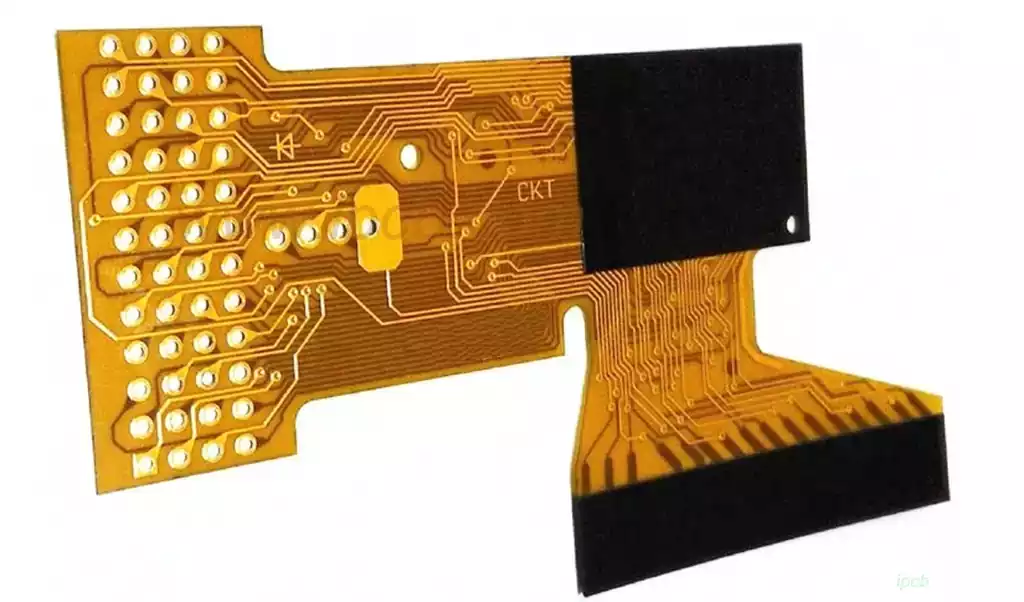

PCB stiffener is a type of sheet used to enhance the structural strength and stability of circuit boards. It is usually made of high-strength, high-rigidity materials, such as metal or special plastics. By pasting or fixing it on the key parts of the circuit board, PCB stiffener can effectively improve the overall strength and bending resistance of the circuit board, and prevent deformation or damage caused by external forces during transportation, installation and use.

The role of the reinforcement plate is to give flexible pcb reinforcement, in order to be able to successfully mount components on top of the FPC, the reinforcement plate has the role of maintaining the stability of the FPC board shape;

Why flexible boards should be reinforced?

PC is called a flexible circuit board because it uses a soft substrate, which makes it flexible to bend and fold to adapt to a variety of complex spatial layout. However, this flexible trait also poses a problem in terms of its relatively low mechanical strength. In some specific application scenarios, especially those that require frequent bending or may be subjected to external impacts, the flexibility of flexible circuit board may not be able to meet the requirements of stability and durability. Reinforcement of Flexible pcb is therefore necessary. The reinforcement process usually involves adding one or more layers of material to the flexible pcb substrate to increase its overall structural strength and rigidity. Such reinforcing measures not only improve the FPC’s bending resistance, but also effectively prevent tearing or fracturing during use.

Another important reason for flexible circuit board reinforcement is to enhance its load-bearing capacity. In some applications, it needs to carry extra weight or withstand external forces, such as in industrial control equipment or automotive electronic systems. By adding reinforcement to these boards, we can significantly increase their load capacity and ensure that the entire system does not fail due to the failure of the FPC when the device is in operation.

In addition, reinforcing FPC also helps to improve their environmental resilience. In extreme operating environments, such as high temperatures, high humidity, or highly corrosive conditions, the performance and service life of flexible pcb board can be severely impacted. In order to enhance the stability and reliability of the FPC in these harsh environments, we usually use the addition of special materials with high temperature resistance, chemical resistance and other characteristics of the reinforcement. In this way, the service life of the FPC can be extended, can better adapt to a variety of complex and changing working environment.

FPC reinforcement is not an integral part of the circuit board design. It will not bend the circuitry and will protect the integrity of the part’s solder joints. The following are the uses of FPC flexible circuit boards using stiffener boards:

- Mechanically support specific areas of a circuit board containing SMT and/or PTH components.

- Maintaining the desired thickness in a flexible circuit board.

- To support FPC flexible circuit board assemblies and connectors.

- Confine flexible parts to rigid areas as required.

- Facilitate better handling of thin circuit boards.

- Keeps certain areas of the flexible circuit board flat and stable.

- Meets Zero Insertion Force (ZIF) connector specifications.

- Increase the bending radius of the circuit at the intersection of the rigid and flexible parts to avoid stress on the flexed parts during multiple bending operations.

Reinforcement plate material can be generally categorized into: FR4, PI, steel sheet and so on;

FR4 material can also be divided into halogen and halogen-free materials, general FPC stamping molding, FR4 edge prone to produce burr bad, part of the improved product can be better to improve this bad.

PI reinforcement is generally used for gold finger bit reinforcement, in order to facilitate the insertion of the gold finger inside the connector;

Reinforcement steel is generally used SUS304 material, this material has the following two characteristics:

a. Weakly magnetic, will not have an impact on magnetic sensitive products such as motors.

b. Stainless, bright surface, will not oxidize discoloration.

Reinforcing steel sheet can be generally divided into: ordinary reinforcing steel sheet, nickel-plated reinforcing steel sheet;

Ordinary reinforcing steel sheet is used for general products without reinforcement grounding requirements;

Nickel-plated reinforcing steel used for products with grounding requirements, nickel stability is good, to ensure a lower resistance value;

PCB stiffener plays an irreplaceable role in enhancing the structural strength and stability of FPC flexible circuit boards. Through reinforcement, FPC can better cope with the external forces during transportation, installation and use, prevent deformation and damage, and ensure the smooth placement of components and the stable operation of the circuit board. In addition, it can also enhance the carrying capacity and environmental adaptability of FPC, extend its service life, so that it can better adapt to a variety of complex and changing working environment.