Wafer testing is for each grain on the wafer for needle test, in the detection head mounted on a gold wire made of fine as a hair of the probe, and the contact on the grain to contact, test its electrical characteristics, unqualified grains will be marked,and then when the wafer according to the grain as a unit to cut into an independent grain, marked with a mark of the unqualified grains will be eliminated,and no longer carry out the next process, so as to avoid futilely increase the cost of manufacturing.

After the completion of wafer manufacturing, wafer testing is a very important step of testing.This step of the test is the report card of the wafer production process. During the test process, the electrical capability and circuit function of each chip is detected. Wafer testing is also known as chip testing or wafer electrical testing.

Wafer testing is one of the main chip yield statistics. As the area of the chip increases and the density increases the cost of wafer testing is increasing. As a result, chips require longer test times as well as more sophisticated and complex power supplies, mechanical devices, and computer systems to perform the test work and monitor the test results. Visual inspection systems are also becoming more sophisticated and expensive as chip size increases. Chip designers are being asked to introduce test patterns into storage arrays. Test designers are exploring ways to make the test process more streamlined and efficient, such as using simplified test procedures after passing chip parameter evaluations, as well as interlaced testing of chips on wafers or testing of multiple chips at the same time.

Wafer testing can be divided into whole-crystal testing, radial testing and slice testing.

- Whole Crystal Test

Whole-crystal test is to connect the test points to the various pins of the wafer, through the automatic test system for the entire wafer for comprehensive testing. Its main processes are as follows:

(1) Design the test program. According to the design requirements of the ic testing, design the test program, including test mode, test range and test parameters.

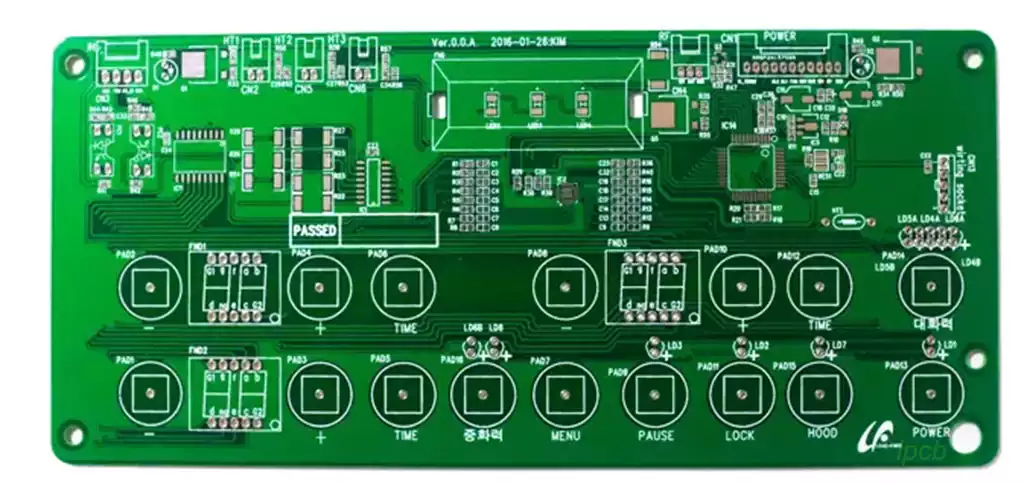

(2) Create test carrier board. According to the test program, create the corresponding test carrier board, and assemble the test head, test cable and test device, etc. onto the test carrier board.

(3) Insert the wafer into the test carrier board. Insert the test carrier board and wafers into the corresponding test equipment, adjust the position of the test head and test devices to ensure the quality and reliability of the test signal transmission.

(4) Test data processing. Transfer the test results to the computer for data processing and analysis, resulting in a test data report. - Radial test

Radial test is the test point installed in the ring pin of the wafer, the chip along the radial ray on the test. Its main processes are as follows:

(1) Design the test program. According to the design of the interface between the chip and the wafer, design the test program, including the test range, test parameters and test mode.

(2) Create test carrier board. According to the test program, create the corresponding test carrier board, and assemble the test head, test cable and test device, etc. onto the test carrier board.

(3) Insert the wafer into the test carrier board. Insert the test carrier board and wafers into the corresponding test equipment, and adjust the position of the test devices so that they can make contact with the ring pins of the wafers.

(4) Test data processing. Transfer the test results to the computer for data processing and analysis, resulting in a test data report. - Slice test

Slicing test is to test each piece of the wafer after cutting it into small pieces. Its main processes are as follows:

(1) Make slicing samples. The wafer is cut into small pieces and processed into the shape of the sample to be tested.

(2) Processing the test sample. Make test points on the surface of the test sample, and connect the test device and test instrument.

(3) Test data processing. Transmit the test results to a computer for data processing and analysis, resulting in a test data report.

In the field of chip manufacturing, wafer testing is undoubtedly a key part of ensuring product performance and reliability. With the continuous progress of chip technology, the requirements for testing are also increasing. From whole-crystal test to radial test to slice test, each test method has its unique advantages and application scenarios. However, no matter which test method is used, the ultimate goal is to screen out unqualified wafers and ensure that the chips entering the next process are of high quality and reliable. Wafer testing is a key step to ensure the quality of the chip, and is of great significance to improve chip performance and reduce costs.