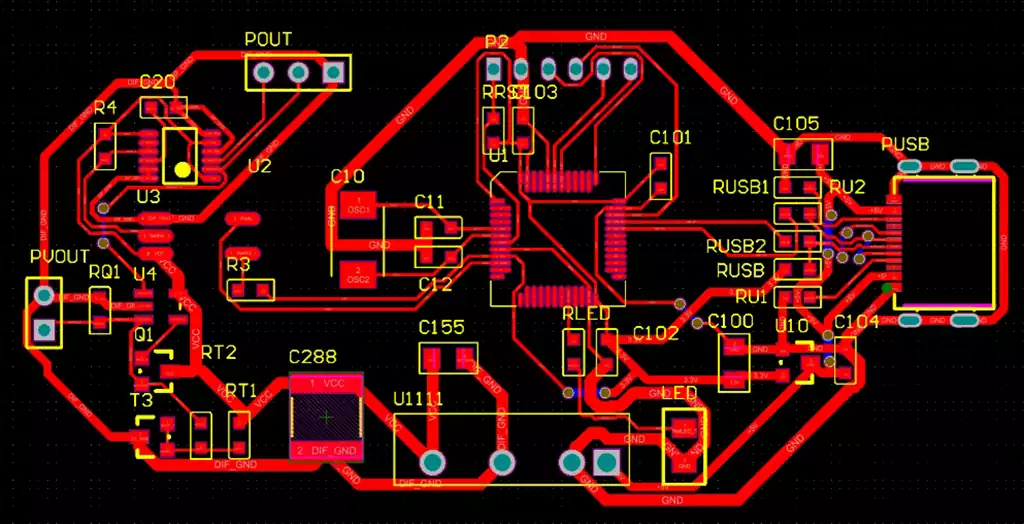

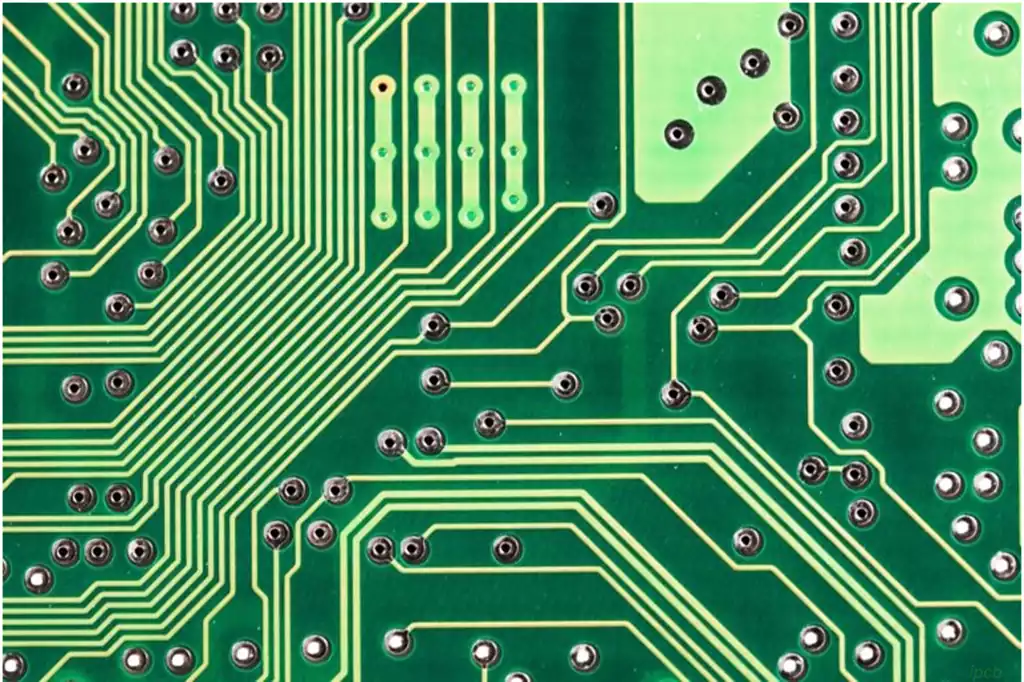

Residual copper in circuit boards is a common by-product of the manufacturing process, and excessive residual copper not only occupies space, but also may cause pollution to the environment. Therefore, how to remove copper from pcb has become the focus of attention of the majority of enterprises.

Residual copper refers to the copper foil that has not been polished off, which can cause short circuit, leakage and other safety problems in electronic products. The main reasons for the copper residual problem are as follows:

- Improper control of the plating process, such as too long plating time, uneven current density, etc., will lead to the accumulation of residual copper;

- Uneven wear and tear of wire brushes and abrasive cloths, resulting in copper foil residue;

- Incomplete chemical cleaning and residual chemicals can also cause copper residue.

Hazards

- Connection failure

It will cause the connection to be easily disconnected, thus affecting the normal operation of electronic products. At the same time, the circuit board copper sinking will also lead to the wire is not smooth, resistance increases, thus affecting the transmission of current and the normal use of electronic products. - Current overload

Will lead to the thickness of the copper layer is too thick, resulting in current overload problems. The overload problem will aggravate the work of the electronic devices, resulting in an increase in the temperature of the device, thus affecting the overall performance of the electronic products. - Short circuit and open circuit

It will lead to poor contact, short circuit, open circuit and other faults, thus affecting the normal operation of electronic products.

How to remove copper from pcb

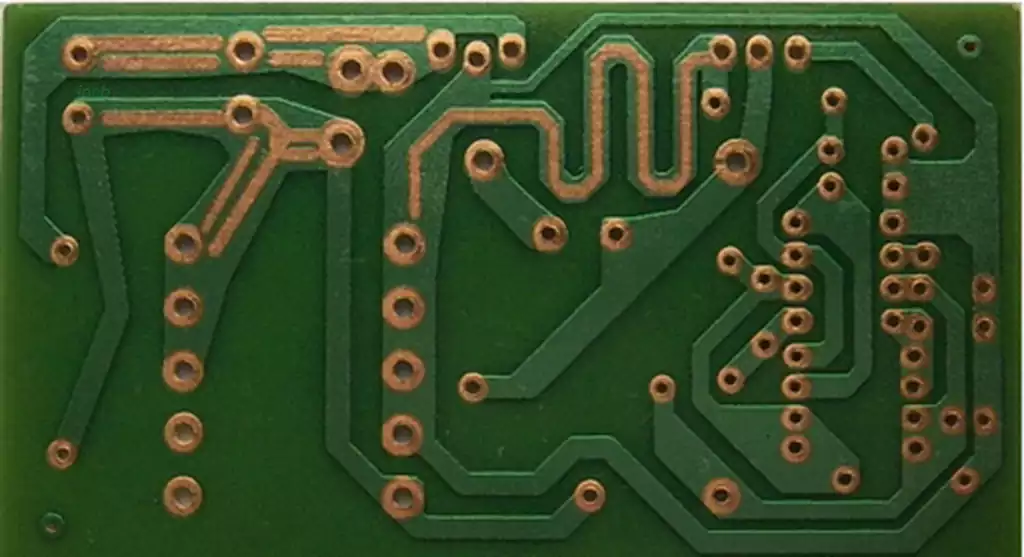

- Mechanical polishing

Mechanical polishing is a common method to deal with copper residue. This method requires the use of equipment such as hydraulic presses or drilling machines to remove copper residues from the pcb board holes. This method is applicable to the larger diameter of the hole, more residues, but will also bring a rougher surface of the hole wall. - Chemical treatment

Chemical treatment is a milder method of copper residue treatment in the pcb board hole. It uses an acidic or alkaline chemical solution to break down the residue and dissolve it. This method is applicable to the hole diameter is small, less residue. However, it should be noted that the chemical treatment needs to reasonably control the concentration of the solution and processing time to avoid damage to the pcb plate itself. - Electrochemical treatment

Electrochemical treatment is a highly efficient method of copper residues in the holes of the pcb substrate. This method uses electrolyte to dissolve copper impurities in the hole, and through the action of the current to remove copper impurities from the hole. This method is faster, more controllable, and does not cause damage to the printed circuit board. But the method requires more specialized equipment and technology, the operation is more difficult. - Recycling

Recycling is a common and environmentally friendly way of processing. Residual copper can be re-purified for the manufacture of new printed wiring boards or other copper products. Through reasonable recycling and reuse, it can not only realize the recycling of resources, reduce the consumption of natural resources, but also reduce production costs. Therefore, many enterprises choose to recycle and reuse the residual copper, which not only realizes economic benefits, but also protects the environment. - Use the residual copper for landfill or incineration to generate electricity.

This approach requires cooperation with environmental protection authorities and ensures compliance with relevant environmental regulations and standards. Landfilling or incinerating copper residues for power generation can fully utilize its energy value while reducing land and air pollution. However, it is important to note that the process of incineration produces harmful gases such as carbon dioxide, and emissions need to be effectively controlled to minimize the impact on the atmosphere.

Precautions

- Before disposing of copper residues, the pcb substrates need to be cleaned and surface treated with appropriate equipment.

- For different residues and different pcb boards, it is necessary to choose the appropriate treatment method. 3.

- In the treatment process, you need to pay attention to safety and environmental protection issues, to avoid harm to the human body and the environment.

How to remove copper from pcb, needs to choose according to the actual situation of mechanical polishing, chemical treatment or electrochemical and other efficient methods to ensure safety and environmental protection, to protect product quality.