The world of integrated circuits (ICs) and their packaging is constantly evolving, with new technologies emerging to meet the increasing demands for performance, reliability, and miniaturization. Among the various IC packaging technologies, the LGA IC package has gained prominence for its unique design and advantages. This article provides a detailed overview of the LGA IC package, exploring its key features, advantages, and diverse applications.

Key Features of the LGA IC Package

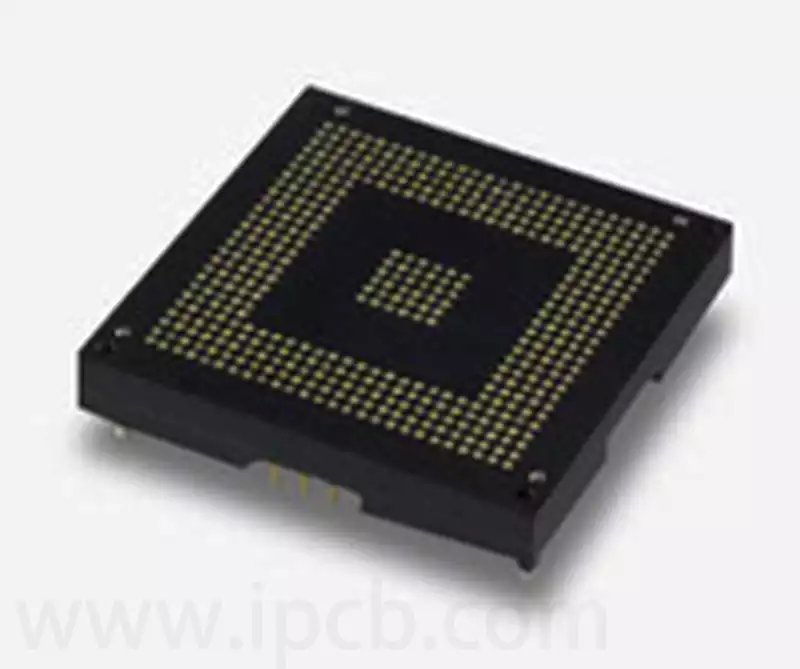

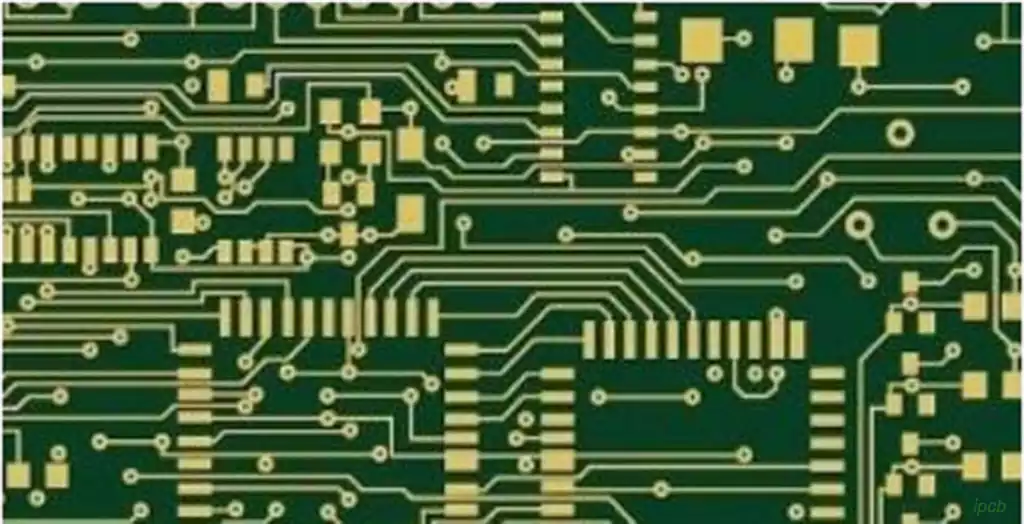

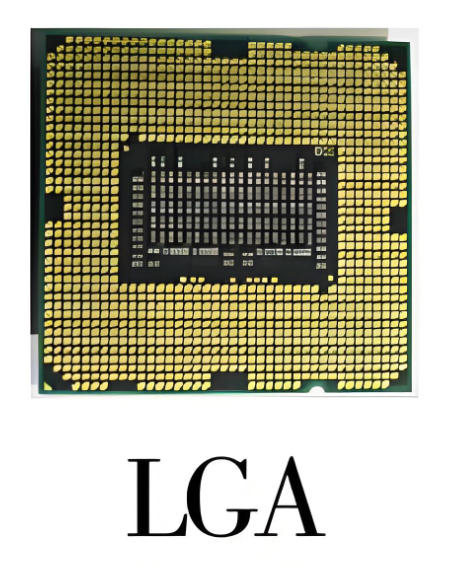

The LGA IC package (Land Grid Array) is distinguished by its use of flat contact points or “lands” on the bottom of the package to establish electrical connections with the printed circuit board (PCB). Unlike traditional packages that rely on pins, the LGA package offers several distinct features:

- Flat Contact Points: The LGA package utilizes flat lands instead of pins, reducing the risk of damage during handling and assembly.

- High-Density Interconnects: LGA packages can support a large number of connections in a compact footprint, making them ideal for high-performance applications.

- Improved Thermal Performance: The design allows for better heat dissipation, crucial for maintaining the performance and longevity of high-power ICs.

- Surface-Mount Technology (SMT) Compatibility: LGA packages are compatible with SMT processes, facilitating automated assembly and reducing manufacturing costs.

Advantages of the LGA IC Package

The LGA IC package offers numerous advantages that make it a preferred choice in various applications:

Enhanced Electrical Performance

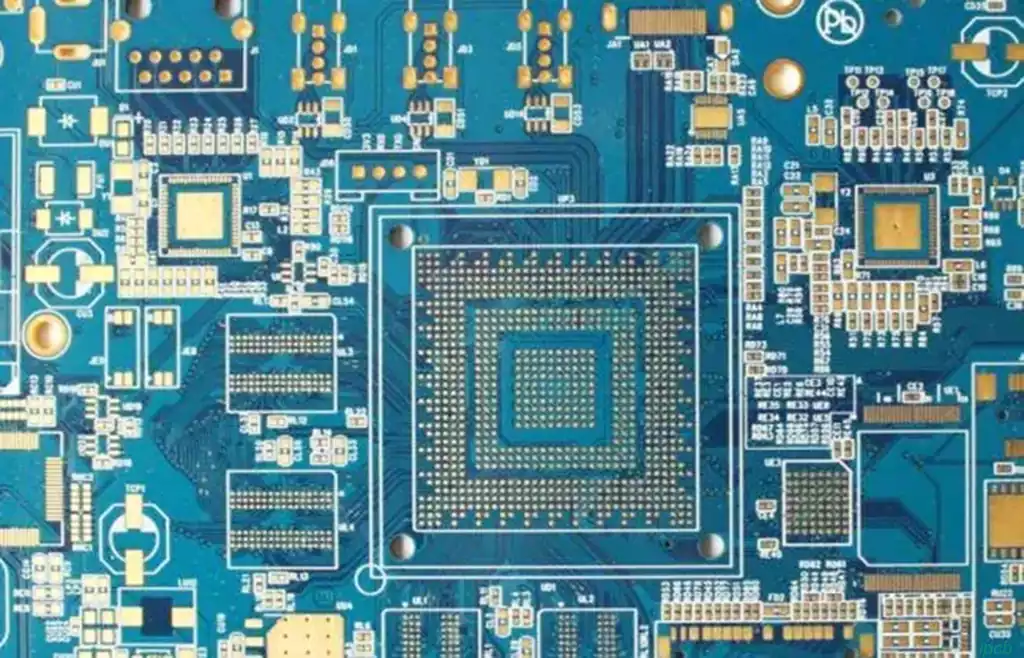

One of the primary benefits of the LGA IC package is its superior electrical performance. The flat contact points provide a shorter and more direct path for electrical signals, minimizing inductance and resistance. This results in improved signal integrity and faster data transmission rates, which are essential for high-speed applications such as processors and memory modules.

Superior Mechanical Stability

The robust design of the LGA package ensures mechanical stability and reliability. The absence of fragile pins reduces the likelihood of mechanical failures during assembly and operation. This makes LGA packages particularly suitable for applications that require high reliability, such as aerospace and automotive electronics.

Efficient Heat Dissipation

Thermal management is a critical aspect of modern electronic devices. The design of the LGA IC package facilitates efficient heat dissipation by allowing direct contact between the IC and the heat sink or PCB. This helps maintain optimal operating temperatures, thereby enhancing the performance and lifespan of the IC.

Scalability and Flexibility

LGA packages offer scalability and flexibility in terms of design and application. They can be customized to accommodate a wide range of IC sizes and configurations, making them suitable for diverse applications, from compact mobile devices to large-scale server systems.

Applications of the LGA IC Package

The versatility and performance benefits of the LGA IC package make it an ideal choice for a wide array of applications across different industries:

Consumer Electronics

In the consumer electronics sector, LGA packages are widely used in devices such as smartphones, tablets, and laptops. The compact size and high-density interconnects of LGA packages enable manufacturers to design sleek, high-performance devices that meet the demands of modern consumers.

Telecommunications

Telecommunication equipment, such as routers, switches, and base stations, requires reliable and high-speed ICs to handle large volumes of data. The superior electrical performance and thermal management capabilities of LGA packages make them well-suited for these applications.

Automotive Electronics

Automotive electronics demand robust and reliable ICs that can withstand harsh operating conditions. The mechanical stability and efficient heat dissipation of LGA packages ensure the reliable performance of critical automotive systems, including engine control units (ECUs), infotainment systems, and advanced driver-assistance systems (ADAS).

Industrial and Medical Equipment

In industrial and medical applications, the reliability and performance of electronic components are paramount. LGA packages are used in various industrial control systems, medical devices, and diagnostic equipment, where their durability and superior electrical characteristics ensure accurate and consistent operation.

High-Performance Computing

High-performance computing (HPC) systems, including servers and data centers, require ICs that can handle intensive processing tasks with high efficiency. The LGA IC package is a preferred choice in this domain due to its ability to support high-speed data transfer and effective thermal management, which are critical for maintaining the performance of HPC systems.

Manufacturing and Assembly Considerations

The adoption of LGA IC packages in various applications also brings specific manufacturing and assembly considerations. Understanding these factors is crucial for ensuring the successful implementation of LGA packages in electronic designs.

Soldering Techniques

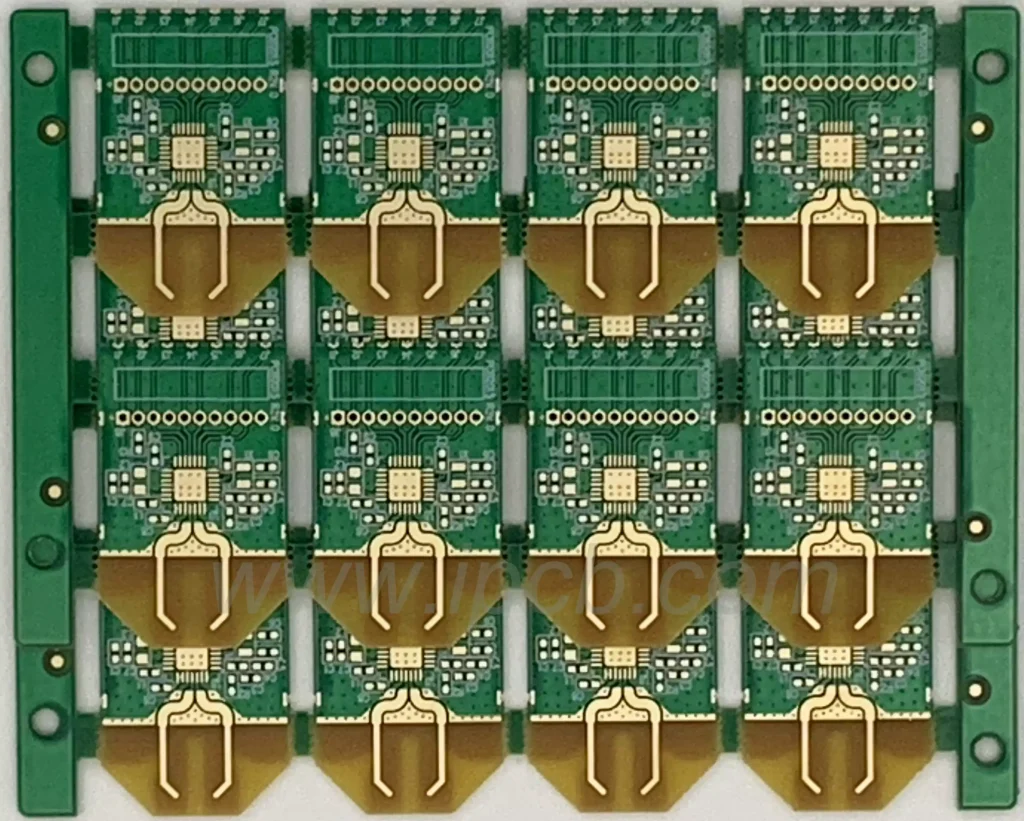

LGA packages rely on surface-mount technology (SMT) for assembly. The soldering process involves applying solder paste to the PCB pads, placing the LGA package on the board, and then reflow soldering to create reliable connections. Ensuring precise alignment and adequate solder volume is essential to achieve optimal electrical and mechanical performance.

Inspection and Testing

Given the critical nature of the connections in LGA packages, thorough inspection and testing are necessary to verify the integrity of the solder joints. Automated optical inspection (AOI) and X-ray inspection are commonly used to detect defects such as voids, insufficient solder, or misalignment.

Rework and Repair

Reworking LGA packages can be challenging due to the absence of pins and the high density of connections. Specialized rework stations and techniques, such as hot air reflow and underfill removal, are required to repair or replace LGA packages without damaging the PCB or surrounding components.

Future Trends and Developments

As technology continues to advance, the demand for high-performance, compact, and reliable IC packages like the LGA IC package is expected to grow. Several trends and developments are shaping the future of LGA packaging technology:

Miniaturization and Integration

The trend towards miniaturization and integration of electronic devices is driving the need for smaller and more efficient IC packages. Advances in LGA packaging technology, such as the development of ultra-fine pitch LGA packages, are enabling higher integration levels and more compact designs.

Enhanced Thermal Management

With the increasing power density of modern ICs, thermal management remains a critical challenge. Innovations in LGA packaging, such as the incorporation of advanced thermal interface materials and heat spreaders, are enhancing the thermal performance of LGA packages and supporting the development of high-power applications.

Advanced Manufacturing Techniques

The adoption of advanced manufacturing techniques, including additive manufacturing and precision machining, is enabling the production of more complex and customized LGA packages. These techniques offer greater design flexibility and the ability to create tailored solutions for specific applications.

Integration with Emerging Technologies

The LGA IC package is also being integrated with emerging technologies such as 5G, artificial intelligence (AI), and the Internet of Things (IoT). These applications require IC packages that can deliver high-speed data transfer, low latency, and reliable performance, making LGA packages a key enabler of future technological advancements.

Conclusion

The LGA IC package represents a significant advancement in IC packaging technology, offering numerous benefits in terms of electrical performance, mechanical stability, thermal management, and design flexibility. Its applications span a wide range of industries, from consumer electronics and telecommunications to automotive and high-performance computing.

As technology continues to evolve, the role of LGA packages in enabling the next generation of electronic devices will become increasingly important. By understanding the fundamentals, advantages, and applications of the LGA IC package, engineers and designers can make informed decisions to leverage this technology and drive innovation in their respective fields.