Flex pcb production starts with designing the circuit board structure and layout. A flexible circuit board is a printed circuit board that is designed to be flexible and bendable. Unlike traditional rigid circuit boards, flexible circuit boards are made of thin, flexible materials such as polyimide or polyester film. These materials allow the circuit board to conform to a variety of shapes and fit into tight spaces, making it ideal for applications that require flexibility and space constraints.

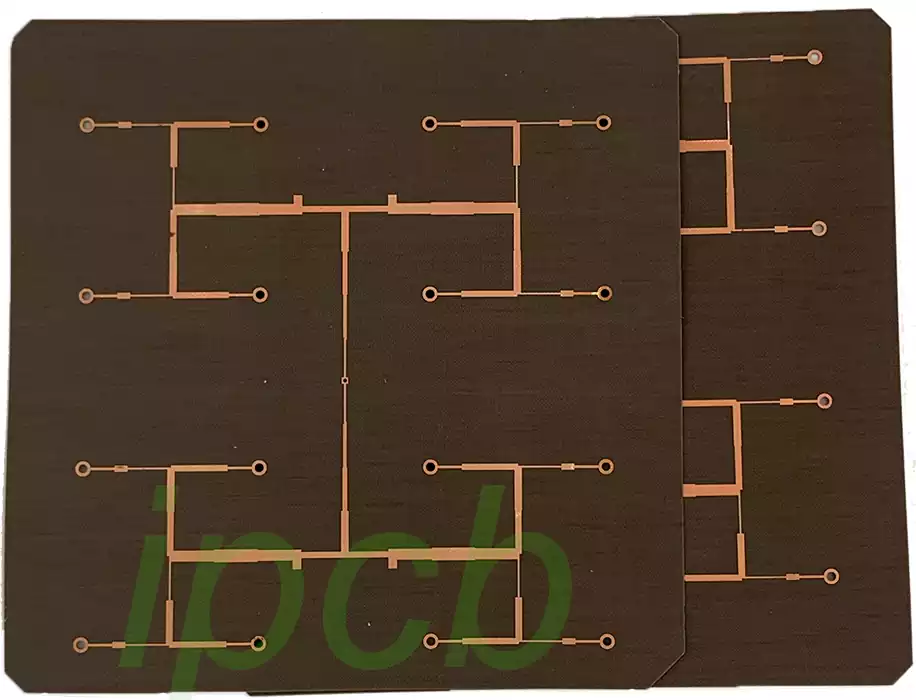

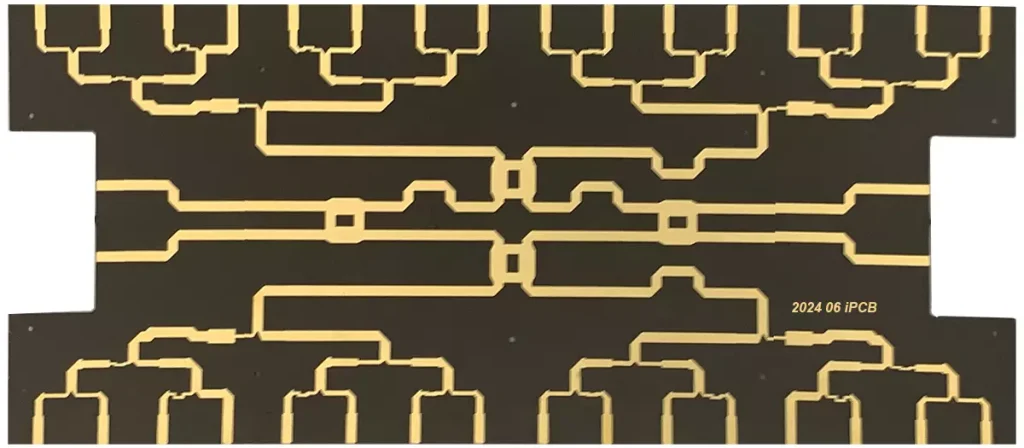

Flexible printed circuit boards consist of a flexible substrate and conductive traces printed on one or both sides. The conductive traces are typically made of copper and covered with a layer of protective insulating material. The flexibility of the substrate allows the PCB to be bent and folded without damaging the conductive traces or components.

Structure of Flexible Circuit Boards

Substrate

The substrate of a flexible circuit board is typically a flexible polymer such as polyimide or polyester. Polyimide is favored for its excellent thermal stability and mechanical properties, while polyester is used for cost-sensitive applications.

Conductive Layer

The conductive layer in a flexible circuit board is typically made of copper. Copper is chosen for its excellent electrical conductivity and flexibility. Depending on the complexity of the circuit design, the copper layer can be single-sided, double-sided, or multi-layered.

Adhesive

The adhesive layer is used to bond the conductive copper layer to the flexible substrate. The adhesive must be flexible and durable to maintain the integrity of the flexible PCB under bending and twisting conditions.

Cover film

The cover film is a protective layer applied to the conductive traces to protect them from environmental factors such as moisture, dust and mechanical damage. The cover film is usually made of the same material as the substrate, such as polyimide.

The flexible circuit board production process is to make a conductor circuit pattern on the surface of a flexible substrate using a photoimaging pattern transfer and etching process. The surface and inner layer of the double-sided and multi-layer circuit board are electrically connected through metallized holes. The surface of the circuit pattern is protected and insulated by PI and glue layer.

Some steps in the flex pcb production process

- Cutting the material

This is a process that every FPC flexible circuit board production must go through. The substrate is initially cut. The purpose of this is to minimize excess waste. If the cut is too large when cutting the material, it will cause waste of excess material. - Chemical cleaning

This step is mainly to clean the oxide layer on the conductive substrate. If the copper oxide on the copper foil is not cleaned, it will cause continuous oxidation to the circuit board, which is a loss to the actual service life of the FPC circuit board. - Inner layer anti-corrosion dry film (FPC flexible circuit board)

This step first requires the circuit to be made on the film, and the circuit on the film is exposed on the substrate with the anti-corrosion dry film (photosensitive film) attached by the exposure machine, so that the circuit can be transferred to the copper foil. - Acid etching (FPC soft board circuit etching)

When using chemical etching, hydrochloric acid or sulfuric acid is used for FPC soft boards, but ammonia is used when etching hard circuits. - Chemical cleaning

This step is to prevent the residual solution of etching from being in the circuit, and then use plasma to clean the foreign matter on the FPC circuit board. - Alignment of the inner layer of the cover film

Before this step, the appearance of the soft board cover film must be formed first, and then the cover film and the FPC circuit board must be aligned and initially fixed on the pad using a soldering iron. - Lamination

Lamination is divided into fast lamination and slow lamination. For this production process that requires multiple laminations, the first lamination is performed using a fast lamination machine. At this time, the maximum thickness allowed after lamination will be clearly stated in the data. After lamination, check whether there are lamination bubbles, overflow glue and other problems. - Baking

This step is to fully combine the circuit board and the glue. The glue used between the copper foil and the cover film flows and spreads after high-temperature baking, which will make the combination more complete. - Printing characters on the FPC circuit board

It is also necessary to make the characters on the film on the screen, and then use the screen to print the characters on the FPC circuit board. Check whether the characters are missing or underprinted. - Final inspection

This is a process that all FPC circuit boards must undergo. This is the last guarantee for the inspection of flexible circuit boards in the production workshop.

Advantages of Flexible PCBs

Flexible PCBs offer several advantages over traditional rigid PCBs:

- Flexibility: The most obvious advantage of flexible circuit boards is their flexibility. They can bend and conform to a variety of shapes, allowing for more compact and space-saving designs.

- Lightweight: Flexible circuit boards are typically thinner and lighter than rigid boards, making them ideal for weight-sensitive applications such as aerospace and wearables.

- Durability: Despite their flexibility, flexible circuit boards are very durable and can withstand repeated bending and folding without damage. This makes them suitable for applications where the circuit board may be subject to constant movement or vibration.

- Reduced assembly time: Flexible PCBs can often replace multiple rigid PCBs and connectors, reducing the number of components and simplifying the assembly process. This can result in faster production times and lower assembly costs.

- Improved signal integrity: Flexible circuit boards can reduce the need for connectors and cables, thereby improving signal integrity by reducing the possibility of signal loss or interference.

Limitations of Flexible Circuit Boards

While flexible PCBs offer many advantages, they also have some limitations. These include:

Higher initial cost: Due to the need for specialized materials and manufacturing processes, the initial cost of flexible PCBs can be higher than that of rigid PCBs.

Complex Design and Manufacturing: Designing and manufacturing flexible PCBs can be more complex than rigid PCBs, requiring specialized knowledge and equipment.

Limited Load-bearing Capacity: Flexible PCBs have limited load-bearing capacity compared to rigid PCBs, making them unsuitable for applications that require high mechanical strength.

Applications of Flex PCBs

Flexible PCBs are used in a wide range of applications across industries:

- Consumer Electronics: Flexible PCBs are commonly used in smartphones, tablets, laptops, and wearable devices, where space is limited and flexibility is required.

- Medical Devices: Flexible circuit boards are used in medical devices such as hearing aids, pacemakers, and implantable devices, where their flexibility and compact size are essential.

- Automotive: In the automotive industry, flexible PCBs are used in applications such as dashboard displays, sensors, and control modules, where they must be able to withstand harsh environments and constant vibration.

- Aerospace: Flexible PCBs are used in aerospace applications such as satellites, aircraft, and missiles, where their lightweight and compact size are critical.

- Industrial: Flexible circuit boards are used in industrial applications such as robotics, automation, and process control, where their flexibility and durability are important.

What is the difference between flexible and rigid circuit boards?

The main difference between flexible and rigid circuit boards is their flexibility. Flexible circuit boards are designed to be flexible and can bend and conform to various shapes, while rigid circuit boards are solid and cannot bend. Flexible circuit boards are generally thinner and lighter than rigid circuit boards and can replace multiple rigid circuit boards and connectors in a design.

Flexible circuit boards offer several advantages over rigid circuit boards, including flexibility, space and weight savings, and improved durability. However, they also have some limitations, such as higher initial costs and complex design and manufacturing processes. The choice of flexible or rigid circuit boards depends on the specific requirements of the application.

What materials are used to make flexible PCBs?

The most common materials used for flexible circuit boards are polyimide and polyester film. Polyimide is the material of choice due to its excellent thermal and mechanical properties. The conductive traces on flexible circuit boards are usually made of copper and covered with a layer of protective insulating material.

Can flexible circuit boards be used in high-temperature applications?

Yes, flexible circuit boards can be used in high-temperature applications. Polyimide, the most common substrate for flexible circuit boards, has a high glass transition temperature and can withstand temperatures up to 300°C. However, the maximum operating temperature of a flexible circuit board also depends on the temperature rating of the components and materials used in the assembly.

How to connect flexible boards to other boards or components?

Flexible boards can be connected to other boards or components through various methods such as:

- Zero Insertion Force (ZIF) Connectors

- Flexible Printed Circuit (FPC) Connectors

- Soldering

- Conductive Glue

- Mechanical Fasteners

The choice of connection method depends on the application, the number of connections required, and the expected environmental conditions.

Automated Optical Inspection (AOI)

Like rigid boards, flexible PCBAs also undergo automated optical inspection to verify that the components are properly placed on the board. The automated optical inspection machine consists of a camera that can effectively detect misplaced or misaligned components and soldering issues such as solder shorts and solder balls.

Automated X-ray Inspection (AXI)

To check the quality of the underlying solder paste, automated X-ray inspection is also performed. This method uses X-ray technology to generate a grayscale image of the board based on the absorption of different types of materials. The X-ray machine helps to detect reflow issues immediately.

Testing

The last step is to test the circuit to see if the FPCB can operate according to the test specifications. Testing can be performed through in-circuit testing and flying probe testing. In-circuit testing is a more efficient method that utilizes a bed of nails contact probe mounted on the device for testing. Flying probe testing is slower but cheaper, and it has movable probes that can test the test network of the PCB. Flying probe testing is more suitable for prototypes and small batch production.

Flex pcb production must consider material selection, bend radius, copper thickness, adhesive selection, component placement, and reinforcement. The manufacturing process of flexible PCBs includes several steps, including substrate preparation, copper lamination, patterning, cover film application, lamination, cutting and drilling, surface treatment, and assembly. In summary, flex pcb production and FPC soft board production processes are key steps in manufacturing flexible PCBs.