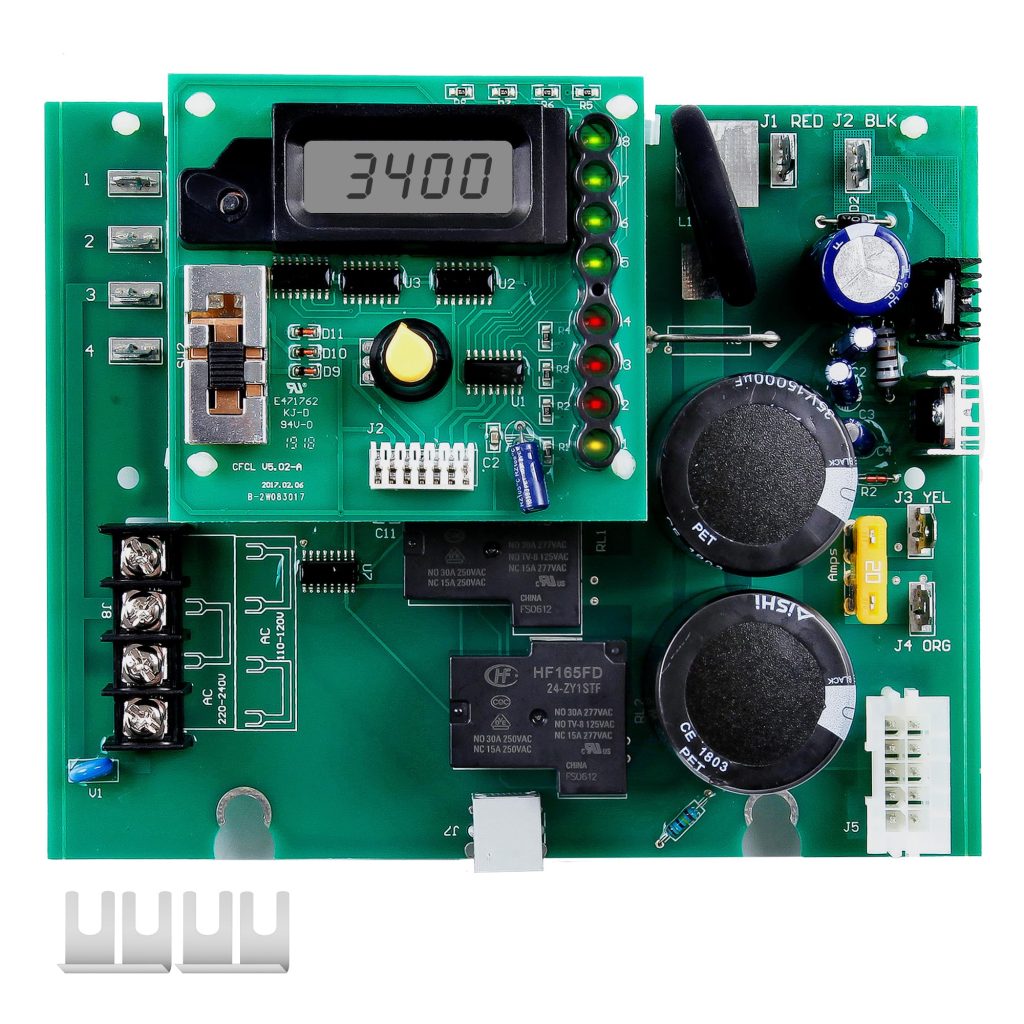

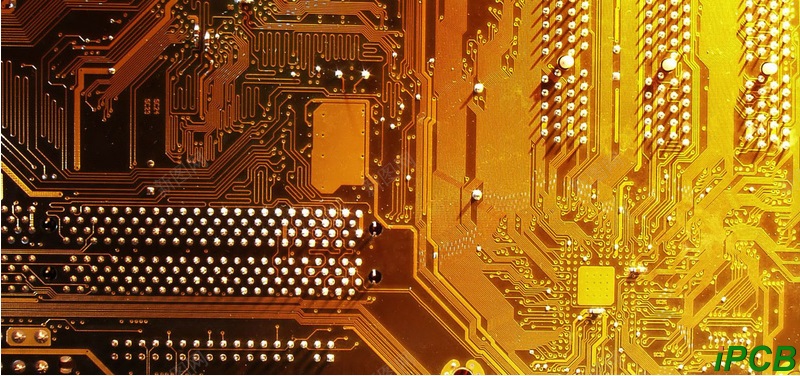

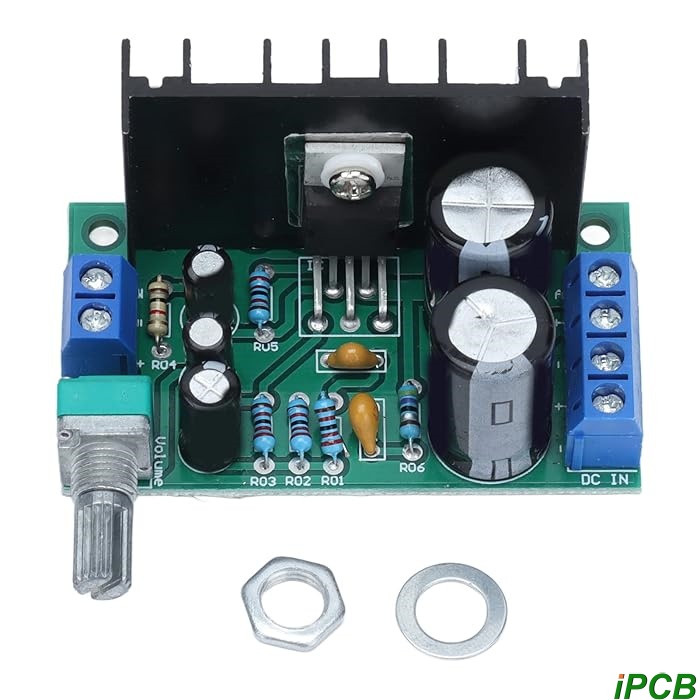

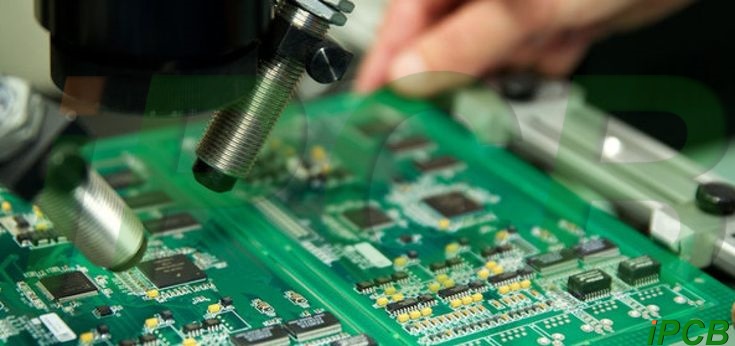

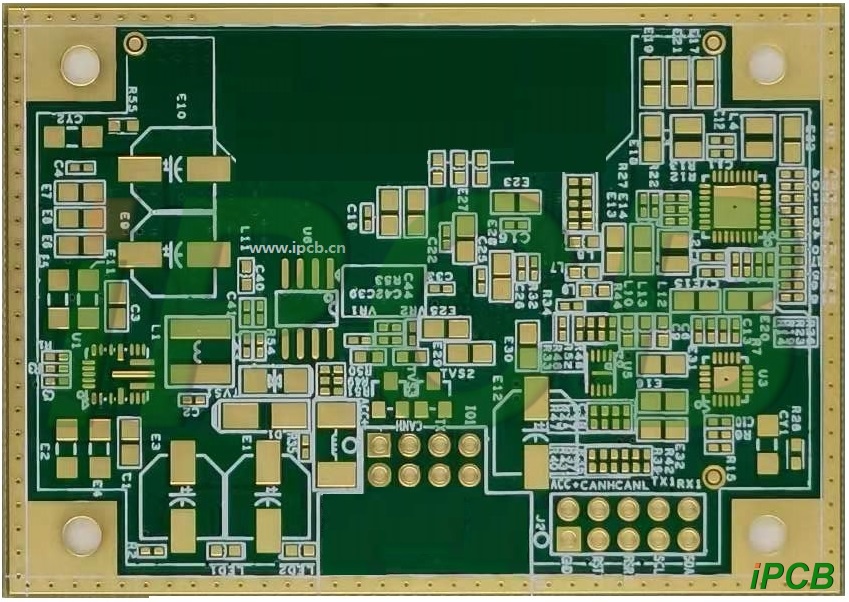

Circuit board Labels

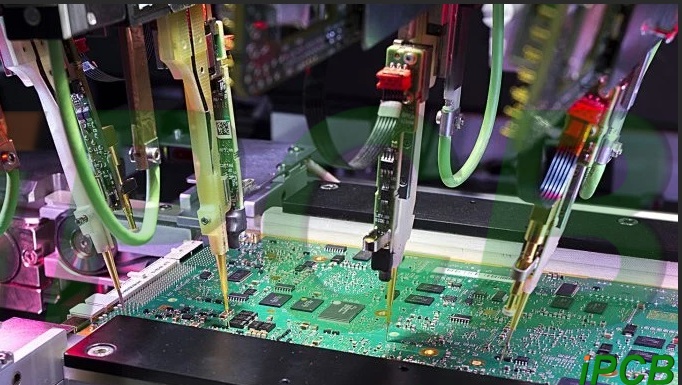

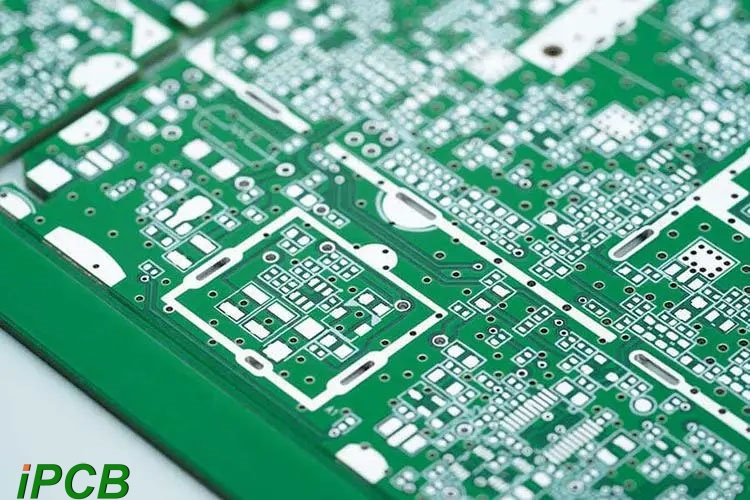

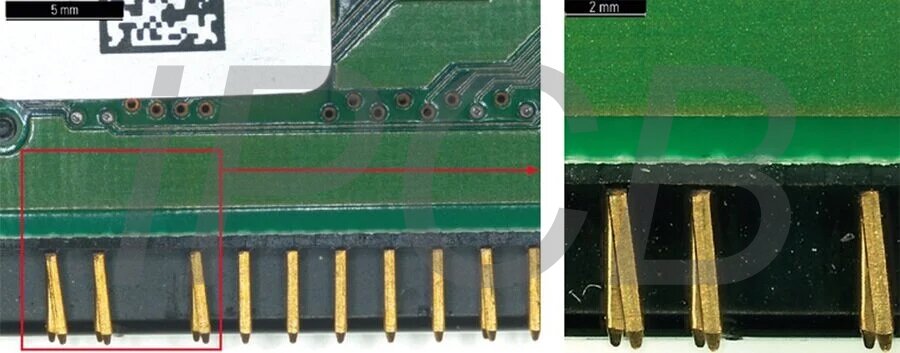

Circuit board Labels,Printed circuit boards (PCBs) are at the heart of most electronic products, including computers, printers, home entertainment devices, “smart” kitchen appliances and mobile phones.Labeling PCBsTo ensure long-term traceability of printed circuit board information, most boards are barcoded to convey the following information: circuit board labels are an important tool for identifying and managing […]