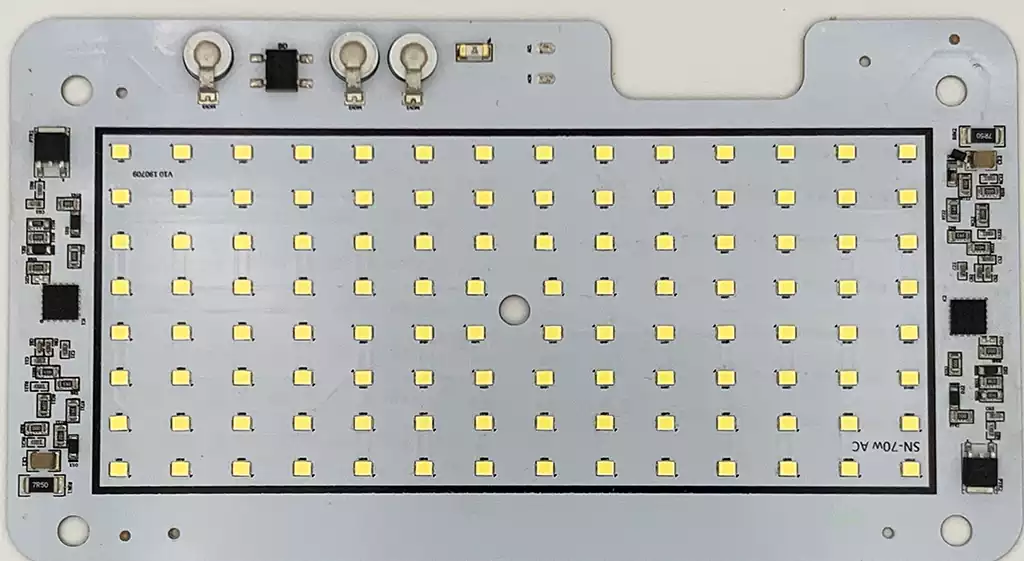

A water temp pcb is a circuit assembly specifically designed to monitor and control the temperature of water. Its core function is to ensure that various water-related systems operate efficiently and safely within a set temperature range. Such circuit boards typically contain several key components to enable precise management and regulation of water temperature.

Components

Temperature Sensors: Water temp pcb’s often incorporate high precision temperature sensors such as thermocouples or thermistors. These sensors acquire water temperature data in real time and convert it into electrical signals.

Control unit: The control unit is responsible for processing the data from the temperature sensors and responding according to preset temperature thresholds. It is able to control the connected heating or cooling equipment to keep the water temperature within the desired range.

Display and Communication Module: Many water temp pcb is also equipped with a display to show water temperature data in real time. In addition, they may have communication interfaces that allow connection to a wider monitoring system for remote management.

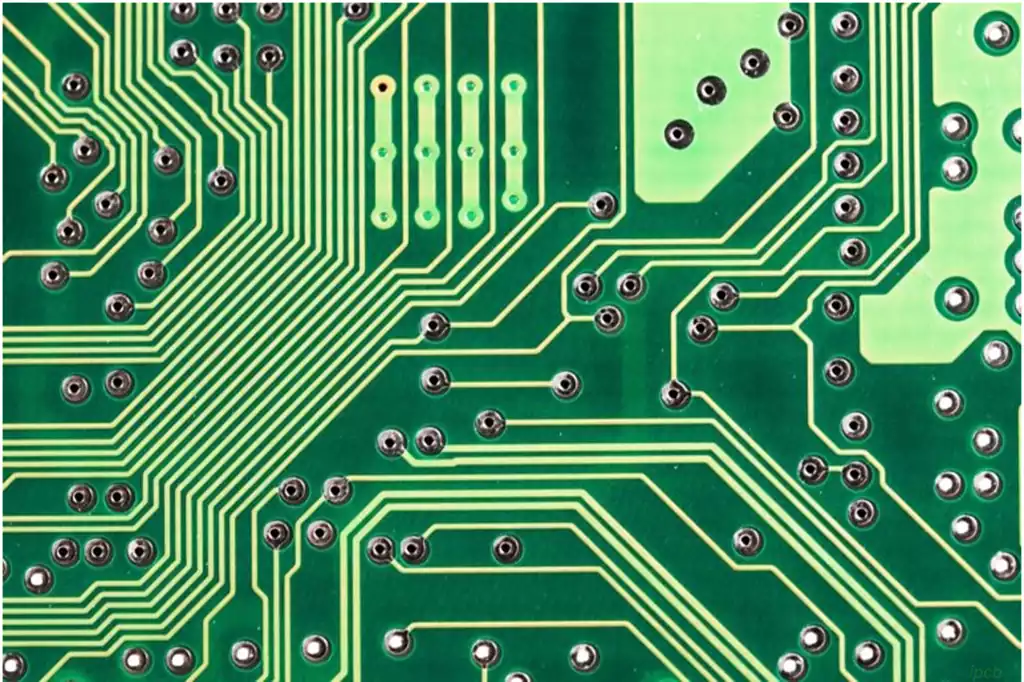

The water temp pcb plays an important role in monitoring and controlling the water temperature and its working principle covers several components:

1.Temperature measurement

Temperature Sensors:The water temp pcb is equipped with temperature sensors,such as thermocouples or NTC thermistors,which are immersed directly in the water to measure the real-time temperature of the water.These sensors are immersed directly in the water to measure the real-time temperature of the water. The sensor converts the sensed temperature change into a corresponding electrical signal.

Signal Conversion:The analogue signal output from the temperature sensor is amplified and processed into a digital signal suitable for processing by the microcontroller.

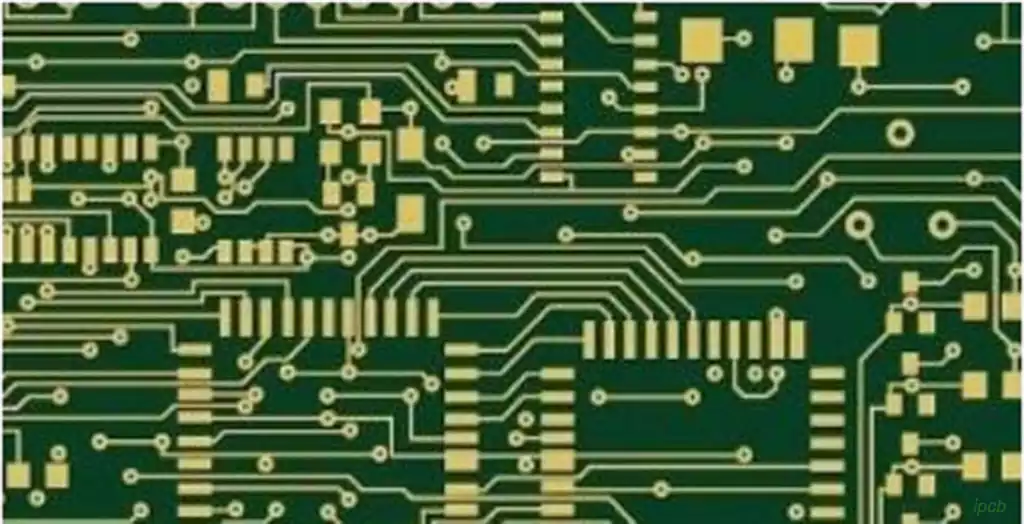

2.Data Processing

Role of the control unit: The control unit is usually a micro-controller or a dedicated integrated circuit,which is responsible for receiving the signal from the temperature sensor and comparing it with the preset target temperature.

Decision logic:Based on the difference between the current water temperature and the target temperature, the control unit calculates the measures to be taken. If the current temperature is below the set value, the control unit signals the activation of the vehicle heating equipment; if the temperature is too high, the cooling system may be activated.

3.Output control

Actuator: Control signals are sent to the heater, cooler or other actuating components via the output drive circuit. Typically, the control unit will control the switching on and off of these devices by means of relays, transistors or solid state relays.

Output Feedback:The operation of the heating or cooling device will change the temperature of the water. Sensors continue to monitor the new temperature and feed it back to the control unit, creating a closed-loop control system that ensures that the water temperature is always within the set range.

4.User Interface and Alarm System

Data Display: Some water temp pcb may be equipped with an LCD or LED display that shows the current water temperature in real time. This provides the user with an intuitive way to monitor the temperature.

Alarm Function: When the water temperature exceeds the safe range, the system may trigger an alarm that emits an audible or optical signal to alert the user to take the necessary action.

Areas of application for water tempe pcb

Domestic heating systems

Central heating: In central heating systems in the home, water temp pcb monitor the water temperature in real time and regulate the operating status of the boiler or heat pump to ensure a comfortable temperature in the room.

Underfloor heating systems: In underfloor heating systems, water temp pcb can control the temperature of the circulating water, helping to warm up quickly and maintain a stable floor temperature.

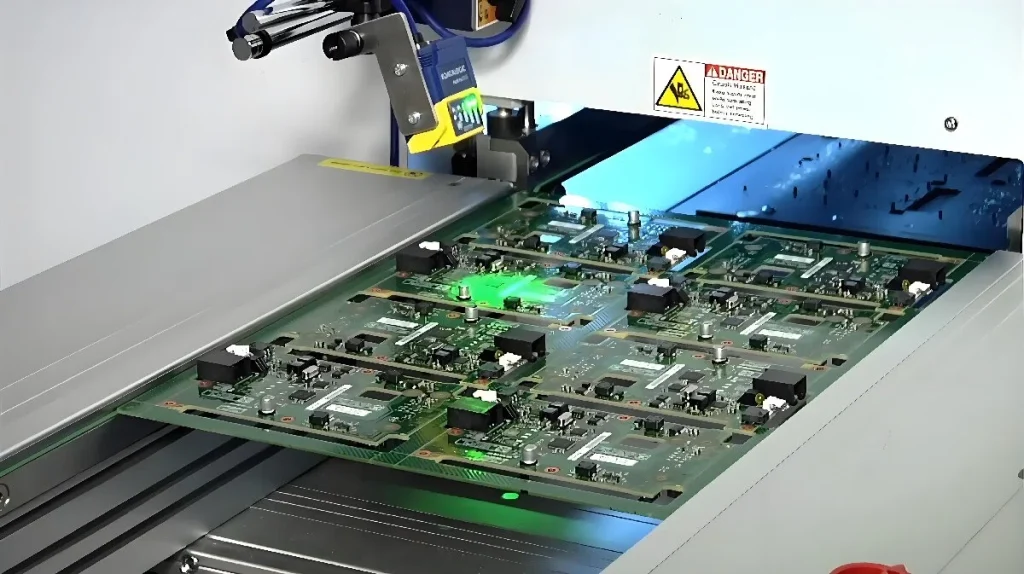

Industrial Equipment Cooling

Production equipment: In the manufacturing industry, many pieces of equipment (e.g. laser cutting machines, CNC machines, etc.) require water cooling to prevent overheating. The use of water temp pcb ensures that the cooling water is at the right temperature to keep the equipment running properly.

Cooling Tower Monitoring: Water temp pcb are used in industrial cooling towers to monitor the temperature of the cooling water in real time for efficient heat exchange and energy management.

Water Treatment Facilities

Wastewater Treatment: In wastewater treatment processes, water temp pcb monitor the temperature of the water to ensure an optimal environment for chemical reactions and biodegradation processes.

Drinking Water Treatment: In drinking water treatment facilities, water temperature monitoring helps manage the disinfection process to ensure safe water quality.

Food and Beverage Industry

Food Processing: Food processing facilities equipped with water temp pcb can effectively manage water temperature to ensure hygiene and quality during food processing.

Beverage Cooling: In beverage production, water temp pcb helps to maintain the proper temperature required during mixing and fermentation.

Medical Equipment

Medical Instruments: Many medical devices, such as haemodialysis machines and temperature-controlled surgical instruments, require precise water temperature control to ensure proper functioning and therapeutic results.

Laboratory equipment: Water temperature circuit boards are widely used in laboratories where microscopes and incubators need to be kept at a constant temperature.

Solar Water Heating Systems

Water Heater Monitoring: Solar water heating systems use water temperature circuit boards to monitor the temperature of the water in the storage tank, ensuring a constant supply of hot water and efficient operation of the system.

Water-temperature circuit boards show significant energy-saving benefits in a number of applications.

Dynamic adjustment: The water temperature circuit board monitors the water temperature in real time by means of an integrated temperature sensor and adjusts it dynamically according to the actual usage. This precise control not only improves the efficiency of the water, but also avoids wasted energy due to overheating or overcooling.

Automated operation: Many water temperature circuit boards are equipped with intelligent control algorithms, which allow them to automatically adjust their operating parameters under different conditions of use, thus minimising energy consumption.

Insulation: Many water temperature circuit boards are combined with insulation to reduce heat loss and ensure that the energy used to heat or cool the water is not wasted. This is particularly important in home heating systems and can significantly reduce home energy bills.

Recycling: In some systems, water temperature circuit boards can be used to recycle water, for example in hot water applications, where the layout and control reduces the waste of large amounts of cold water in conventional systems.

Widely applicable: Water temperature circuit boards can be widely used in water heaters, underfloor heating systems, industrial cooling equipment and other equipment, through appropriate settings and adjustments, can achieve good energy-saving effect. For example, in a heat pump system, a reasonably set temperature threshold can significantly reduce power consumption.

Combination with other energy-saving technologies: Water temperature circuit boards can also be used in combination with other energy-saving technologies such as intelligent control and heat recovery to further improve the overall energy efficiency of the system. For example, the control system can be used to optimise the time at which the water is heated or cooled, making better use of natural energy sources and increasing the efficiency of energy use.

With its excellent water temperature monitoring and control capabilities, the water temp pcb has demonstrated the advantages of high energy efficiency and intelligent management in many fields, becoming an indispensable core technology for water temperature management and driving the continuous progress and development of related systems.