In modern electronic equipment manufacturing, the cost of printed circuit boards (PCBs) represents a significant portion of the total product cost. The custom pcb cost per unit fluctuates due to diverse market demands and technological developments. This article will analyse in detail the main factors affecting the custom pcb cost per unit.

1.Material Cost

The material cost of custom PCB is one of the important factors affecting the price. Typically, the material cost mainly includes substrate materials, line materials, pad materials, etc., and the price of different materials will also vary. For example, FR4 glass fibre substrate is one of the common substrate materials, and its price is relatively low, while the price of high-performance materials such as aluminium substrate and ceramic substrate is relatively high. There are also various choices of wiring materials, such as copper foil, silver paste, etc., and the prices of different materials are different. In addition, the price of the pad material also needs to be considered, and there are generally a variety of options such as metal and metal alloy.

In addition to the price of the material itself, there are some material processing costs also need to be considered, such as substrate surface treatment, line cutting, etc.. These costs are not high, but also need to be taken into account.

2.Labour cost

Labour cost is another important factor that affects the custom pcb cost per unit.The production of circuit boards need to go through a number of links, such as design, plate making, drilling, copper coating, etc., each of which requires the corresponding manual operation. Therefore, the labour cost accounts for a relatively large part of the overall cost.

The level of labour cost depends on two factors, one is the degree of automation of production equipment, and the other is the geographical location of the manufacturing plant. Some advanced production equipment can achieve automation, which reduces the labour cost. The geographical location of the manufacturing plant will also affect the labour cost, some areas of the labour cost is relatively low.

3.Design Cost Design

Cost is one of the necessary costs of custom circuit boards.Design costs mainly include software design costs and hardware design costs. Software design costs mainly refers to the use of PCB design software costs,hardware design costs include the cost of schematic design and wiring design.

Compared with other costs, design costs have relatively few influencing factors,but different design companies charge different rates. Therefore, when choosing a design company, you need to consider its charges.

4.Board Size and Number of Layers

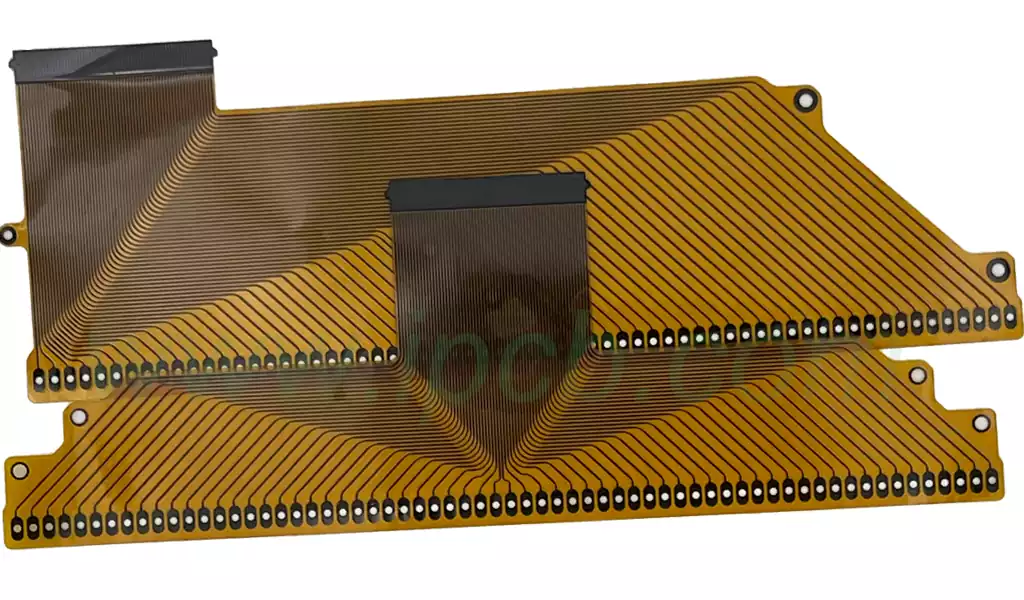

The size of the PCB and the number of layers is an important factor in determining the price. The larger the size, the more raw materials used, the natural rise in cost; at the same time, the increase in the number of layers means a more complex manufacturing process and higher material consumption, the price will also increase significantly.

5.Line and aperture requirements

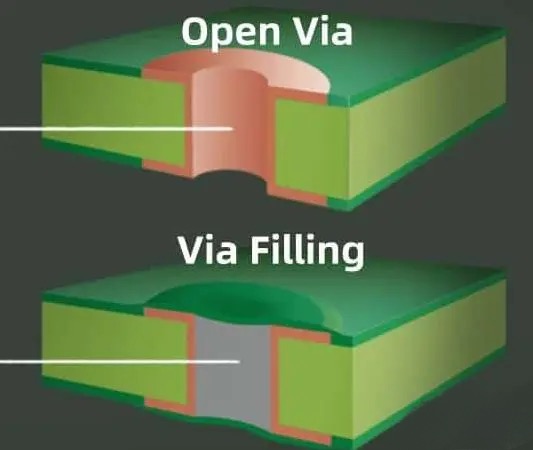

Fine lines and small apertures (e.g. micro-aperture technology) increase the difficulty of manufacturing and require more sophisticated equipment and technical support, so the cost will increase accordingly.

6.Surface treatment

Different surface treatments, such as tin spraying, electroless nickel gold plating (ENIG), silver immersion, gold immersion, etc., have different costs. High-level surface treatment can provide better electrical performance and solderability, but the price is also higher.

7.Other Factors

In addition to the above three aspects of cost, there are some other factors that can also affect the price of custom circuit boards. For example, the order quantity, delivery time and other factors will have an impact on the price. The larger the order quantity, the relatively lower the price; while the urgent delivery of orders need to expedite production, which will increase the cost.

In addition, the function and performance of the custom circuit board will also have an impact on the price. If special features or high performance boards are required, the price will increase accordingly.

The price of custom circuit boards is complex, including materials, labour, design and other aspects of the cost. And different demands and order quantities will also have an impact on the price. Therefore, when choosing custom circuit boards, you need to comprehensively consider the cost of all aspects and make decisions based on actual needs.

The custom pcb cost per unit is affected by a combination of factors, from the choice of materials to the cost of labour, to the complexity of the design and manufacturing requirements, every detail determines the final price. For electronic product manufacturers, in the pursuit of cost control at the same time, but also need to take into account the performance and quality of the product. Therefore, in the selection of PCB manufacturers, should be a comprehensive assessment of its material selection, production processes, design capabilities and service response time, to ensure that the performance of the product to meet the needs of the same time, to achieve maximum cost-effectiveness.