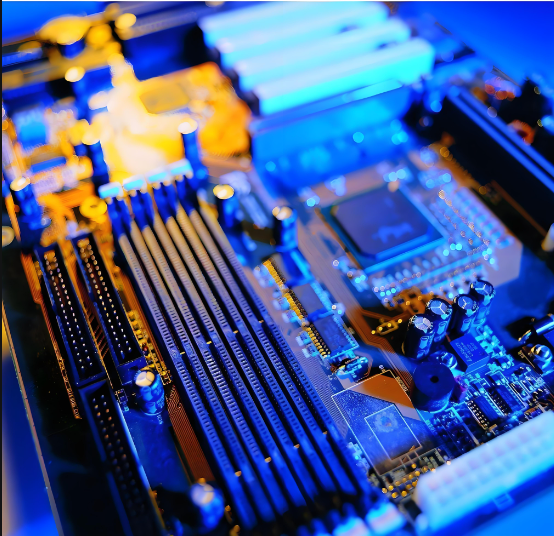

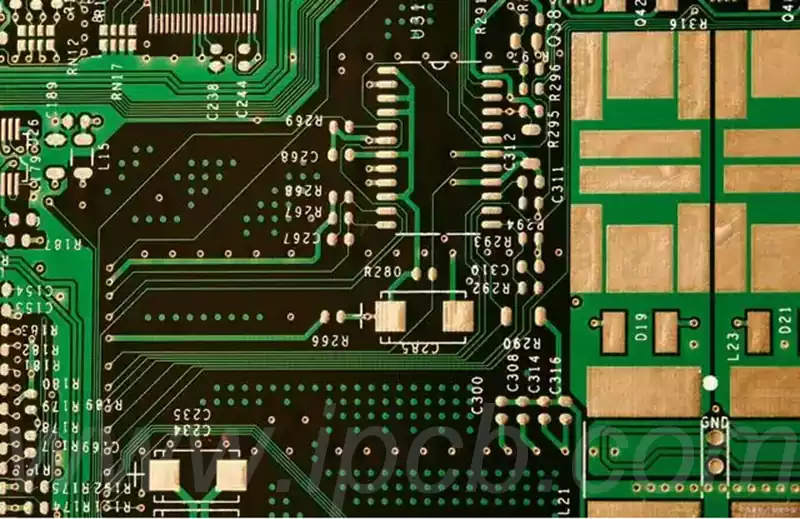

Soldering wire precisely and securely to a pcb board is a fundamental and critical skill in the assembly and repair of electronic equipment. Whether you’re a DIY enthusiast or a professional electronics engineer,mastering this technique can greatly improve your work efficiency and project success rate.In this article,we will take you step by step through the whole process of soldering wires to a pcb board,from the preparation work to the inspection after the completion of the soldering, to ensure that every step of the process is precise and error-free.

Steps on how to solder wire to pcb board:

- Preparation

Before starting the soldering process, prepare the necessary tools and equipment, including wires.PCB board.Soldering wire. Soldering iron etc. At the same time, make sure that there are no other items on your workbench to avoid affecting the efficiency of your work. - Cut the wires and clean the copper foil.

Cut the wires to be soldered and clean the copper foil on the circuit board with sandpaper or a wire brush.This will help to make the wires and the circuit board more closely together, thus improving the quality of the soldering. - Arrange the wires on the board.

Before soldering the wires to the pcb board,arrange and fix the wires in the position where they need to be accessed.This will help you to better connect the wires to the board. - Heat Treating the Wires

In order to solder the wires to the board, you need to heat treat the wires first. Firstly, use pliers to peel back the protective coating on the end of the wire to expose the bare metal wire. Next, heat the wire with a soldering iron so that the heat is evenly distributed and it reaches a solderable state. - Selecting Solder

Before choosing a solder,you need to understand the characteristics and uses of different types of solder.The common types of solder are ‘63/37’. ‘60/40’ and “40/60”,where the number indicates the quality and tin content.For soldering wires to circuit boards,it is recommended to choose ‘63/37’ solder, which has good fluidity and reliable connection results. - Checking the soldering results

After the soldering is completed,check that the connection between the wires and the pcb board is good and that there are no soldering holes or other problems. Make sure that the soldering has no short-circuits,and there are no problems such as poor contact.

Precautions on how to solder wire to pcb board:

1.Keep the soldering iron at the proper temperature when soldering to avoid burnt solder joints or damage to the circuit board;

2.Be careful to avoid short-circuiting between the wire and the pcb board,which can be wrapped with insulating tape or heat-shrinkable tubing;

3.Pay attention to personal safety to avoid causing injuries and smoke hazards to the human body;

4.After completing the welding, check and test to ensure that there is no short circuit or desoldering at the welding place.