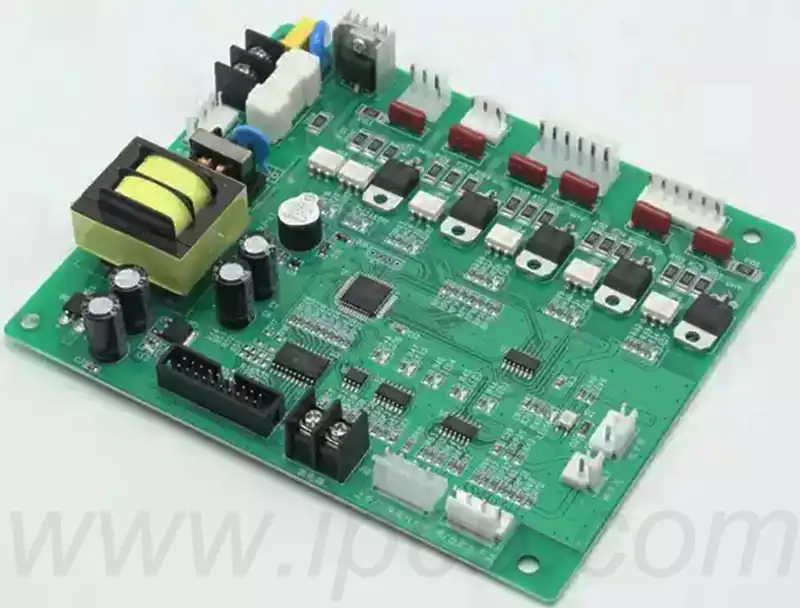

Hot tub circuit boards are usually composed of several functional modules, including power management module, temperature control module, pump drive module, bubble generator control module and so on. These modules work together to realise the functions of the hot tub through complex circuit design and precise component selection.

Among them, the temperature control module is the core part of the hot tub circuit board. It usually consists of a temperature sensor, a microprocessor (such as a microcontroller) and a heating element.The temperature sensor detects the water temperature in the bathtub in real time and transmits the signal to the microprocessor. The microprocessor regulates the water temperature by controlling the on-off of the heating element according to the preset temperature value, ensuring that the water temperature inside the bathtub stays within the comfort range set by the user.

The main functions of the hot tub circuit board include:

Temperature control: precisely controls the heater to maintain the set water temperature.

Pump Management: controls the start, stop and speed of the pump that drives the filtration and jetting system.

Jet control: manages the start and mode of the jets to provide a massage function.

Lighting Control: Controls underwater lighting to create a spa atmosphere.

Safety Protection: Monitors various sensors such as temperature and water level sensors to prevent safety issues such as overheating or dry burning.

Temperature control for hot tub circuit boards

Temperature Monitoring

Hot tub circuit boards utilise temperature sensors to monitor water temperature and relay this information to the control board.Temperature sensors such as the AMPFORT 6600-167,for example,detect temperature changes and send signals to the control system to adjust the heater.Overlay surface mounted reed sensors detect water flow and ensure that the heater only activates when water is circulating, preventing localised overheating.

Heating Control

The control panel monitors the temperature and activates the circulation pumps and heaters as necessary to heat the water. Some systems use Proportional Integral Derivative (PID) controllers to achieve precise temperature control by adjusting the power output of the heating elements. In addition, some designs use a high-temperature resistant electric heating film in series with the thermostat,which is energised to heat the water when the temperature sensor detects that the water temperature is below the set point.

Safety Mechanism

To prevent safety issues such as overheating and dry burning, hot tub circuit boards incorporate a variety of safety mechanisms. For example, some heaters are equipped with overheat cut-offs and pressure switches to ensure that the heater will only operate when the circulation pump is running and will not overheat. Additionally, some systems use two thermostats in series to prevent the failure of a single thermostat from causing the heater to dry out.

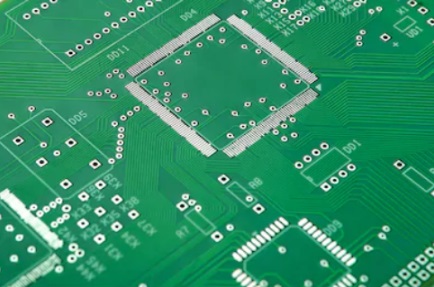

Differences between hot tub circuit boards and regular circuit boards:

Application Environments

Hot tub circuit boards: specifically designed for use in hot tubs, which need to withstand harsh environments such as high temperatures and humidity. These environments place higher demands on the circuit board’s material selection, packaging process, and waterproof performance.

General circuit boards: Widely used in a variety of electronic equipment, such as computers, mobile phones, home appliances and so on. Their application environments are relatively diverse, but usually do not need to withstand extreme conditions such as high temperature or humidity.

Functional Requirements

Hot tub circuit boards: In addition to basic circuit connections and control functions, they also need to have specific functions such as temperature control, pump drive, and bubble generator control. These functions require the board to integrate complex circuit logic and algorithms to achieve.

General circuit boards: According to the needs of specific equipment,may have signal processing, data transmission,power management and other basic functions. Its functional requirements are relatively simple, usually do not need to integrate complex control algorithms.

Safety Requirements

Hot tub circuit boards:Due to the need to contact with water and withstand high temperatures, the safety requirements are extremely high.Circuit boards must be waterproof, moisture-proof,leakage-proof and other safety features to ensure that the user will not be subjected to electric shock or electrocution hazards in the process of use.

Ordinary circuit boards: Although they also need to have certain safety features,they usually do not need to withstand extreme conditions such as high temperatures or humidity, so the safety requirements are relatively low.

Design Complexity

Hot tub circuit boards: Higher design complexity due to the need to integrate multiple specific functions and meet stringent safety requirements. The design of the circuit board needs to consider a number of aspects such as material selection, packaging process, waterproof performance, circuit layout, and so on.

General circuit boards: relatively simple design, usually only need to consider the circuit connection, signal transmission and other basic functional requirements. Its design process is relatively standardised and can be completed using common design methods and tools.

As a core component of modern spa equipment, hot tub circuit boards are designed with precision and strict safety requirements to ensure the comfort and safety of users in the process of use. In the future, with the continuous evolution of smart home technology, hot tub circuit board, as a bridge connecting technology and comfort, is leading the modern spa equipment to a more intelligent, humane direction.