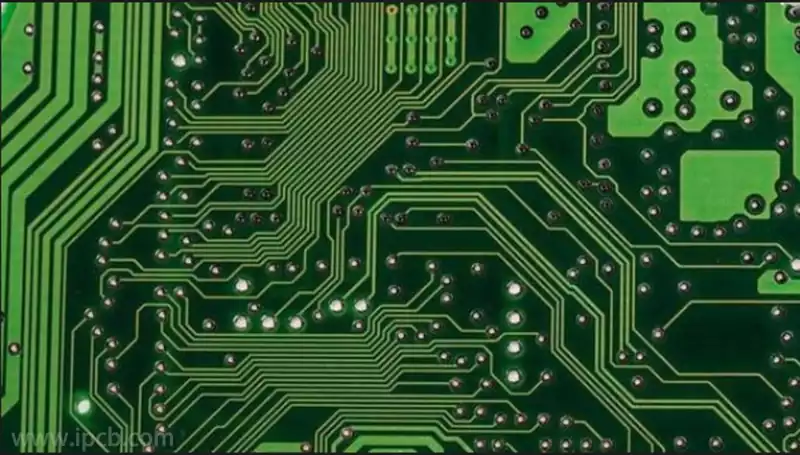

Printed Circuit Board as a key component in the field of electronics, the principle of its work is in the conductive substrate precision etching or printing ‘circuit layout pattern’, as a carrier to fix all kinds of electronic components, and based on the electrical schematic diagram to build a complete circuit, to ensure that the signal transmission and functionality to achieve. Integrated circuit (IC), commonly known as ‘chips’, are miniaturised electronic systems based on semiconductor technology platforms and manufactured through nanoscale precision processing. It highly integrates a large number of transistors, resistors, capacitors and other components to form a modular unit with specific functions, capable of efficiently carrying out complex computing, signal processing and other diversified tasks, with applications covering consumer electronics, industrial control, communication networks and other industry-wide scenarios.

Integrated circuits (ICs) and printed circuit boards (PCBs) play complementary roles in electronic systems. IC is essentially a variety of electronic components (such as transistors, resistors, capacitors, etc.) through the semiconductor micro-nano-processing technology integrated into a single chip of the miniaturised electronic module, often referred to as ‘chip’ or ‘integrated block’, such as the motherboard on the North Bridge chip, CPU core belongs to this category. PCB is etched through the conductive layer to form the circuit path of the substrate, used to carry and interconnect various types of electronic components, including integrated circuit chips.

The core relationship between the two:

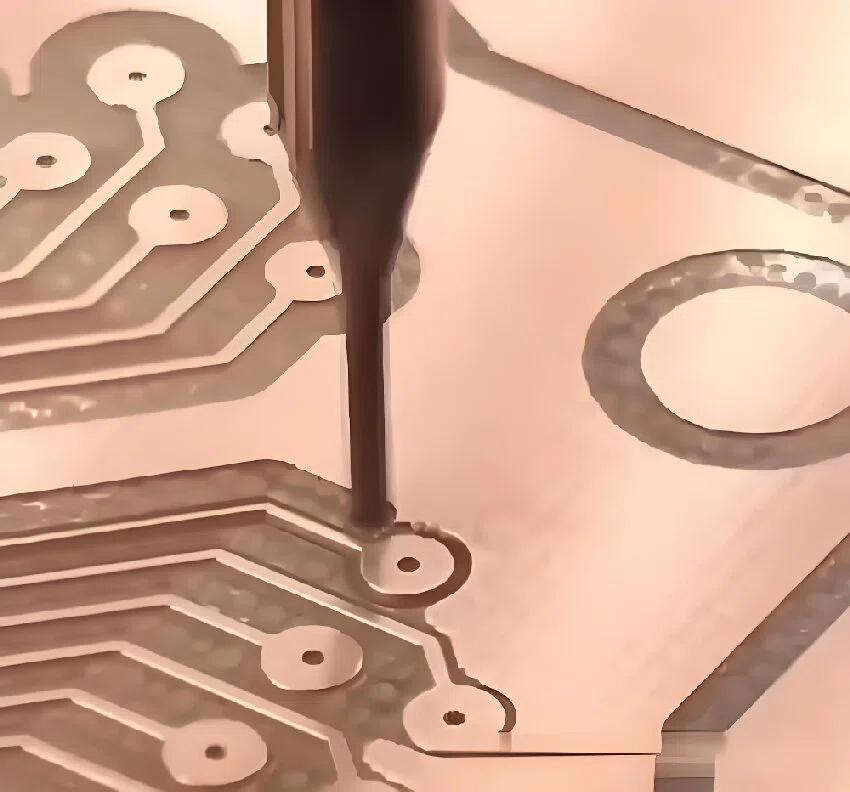

Physical coupling: Integrated circuits are soldered to designated pads on the printed circuit board through surface mount (SMT) or through-hole technology to form electrical and mechanical connections.

Functional synergy: PCB as a carrier, through the preset copper foil alignment network, the integrated circuit and other discrete components, interface devices connected to a complete circuit system, to achieve signal transmission and energy distribution.

Failure characteristics of the difference: integrated circuits once the internal transistor array physical damage (such as electrostatic breakdown, thermal failure), usually need to be replaced as a whole; while the PCB if there is only a weld off or copper foil fracture, it can be restored to functionality through local repair or component replacement.

IC is encapsulated with a specific function of the electronic unit, PCB is to achieve system-level interconnections of the physical platform, the two together constitute the hardware foundation of modern electronic equipment.

The main differences between ic and printed circuit board:

Functional complexity:

Chip as a miniature electronic functional unit, its initial design is focused on the implementation of specific tasks, such as the central processing unit (CPU) form to assume the role of the central data processing, in the form of memory to achieve massive data access, or in the form of sensors to perceive changes in the physical world. Modern chip technology has broken through the physical limits of size and energy efficiency, building parallel computing architectures comparable to supercomputers on nanoscale wafers, and becoming the core driving force in consumer electronics, industrial control, artificial intelligence, and other fields.

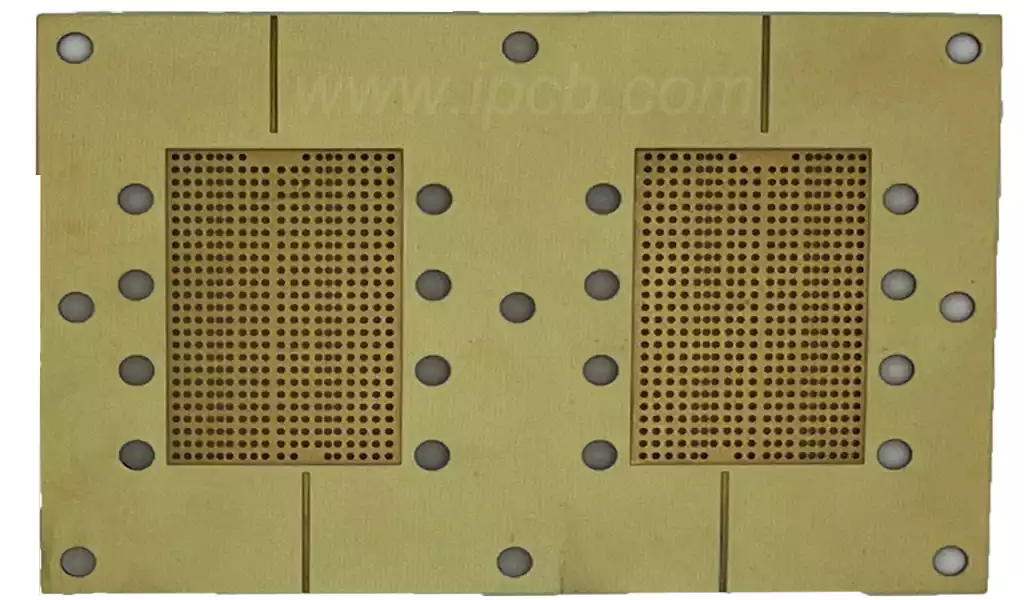

Printed circuit board (PCB) is to undertake the important mission of system-level integration, the essence of which is to build a three-dimensional conductive network on the surface of the substrate through the precision etching process. PCB through the pads, apertures, alignments and other structures, chips, resistors, capacitors, and other discrete components woven into a logic of the circuit topology, to ensure that the electrical signals in the millimetre-level space to achieve nanosecond timing control. In the face of modern electronic products for high speed, high density, high reliability needs, PCB has evolved multi-layer stacking, blind buried holes, impedance control and other advanced processes, in a limited space to build a complex circuit system comparable to large cabinets.

Different Scope of Application

Due to the large size of printed circuit board, it is usually used in large electronic devices or systems, such as computer motherboards, televisions, radar systems and so on. ICs, on the other hand, are usually used in small electronic devices such as mobile phones, laptops, micro drones, wearable devices, etc. due to their miniaturisation and high degree of integration.

Different production processes

The production process of PCBs (Printed Circuit Boards) revolves around two main areas, physics and chemistry, covering core processes such as chemical etching to build conductive lines, electroplating processes (e.g. gold plating) to enhance the reliability of the pads, and thermoforming to achieve inter-layer bonding. In contrast, the manufacture of ICs (integrated circuits) relies heavily on precision engineering at the micro- and nano-scale, involving such ultra-precise operations as photolithography to define nanoscale patterns, multi-layer etching to shape three-dimensional structures, ion implantation to regulate doping concentration, thermal oxidation to generate insulating dielectric layers, and chemical vapour deposition (CVD) or physical vapour deposition (PVD) to build thin-film layers. This essential difference in process dimensions determines the need for IC manufacturing to meet the demanding standards of material purity control, dimensional accuracy management, and defect rate control that far exceed those of printed circuit boards, resulting in a technological leap from the micron to the nanometer scale.

Different Costs

The production cost of PCB is relatively low, which makes it more advantageous in mass production and application. ICs, on the other hand, are relatively expensive to produce, largely due to their complex designs and processes as well as high equipment investments. However, once in mass production, the unit cost of ICs can be significantly reduced, so ICs remain economical in many applications.

Simply put, an IC is a general-purpose circuit integrated onto a single chip; and a printed circuit board is a substrate used to mount and connect various electronic components, including ICs.