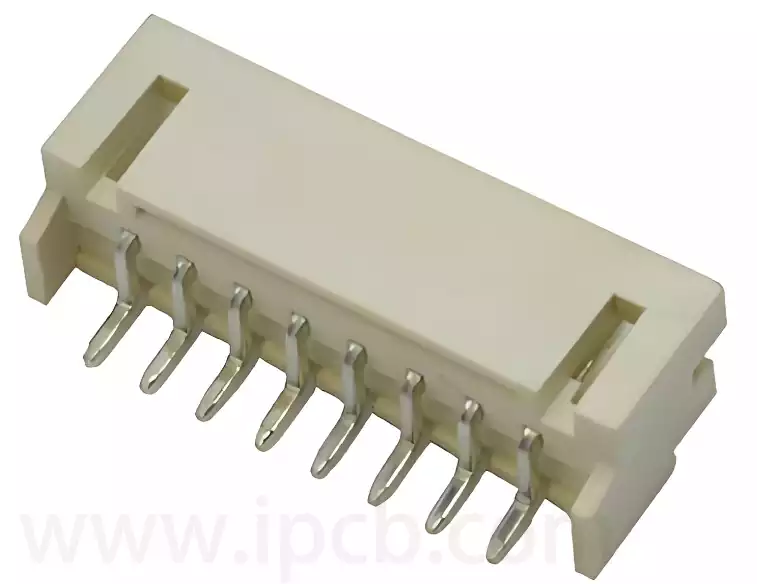

SMT connectors are connectors assembled using SMT technology. In specific use, SMT connectors like SMT components, for the connector pads, are directly affixed to the surface of the circuit board, and no longer need to be like the traditional TH connectors need to be pierced to install.

SMT connectors are divided into: lying paste connector (SMT) and vertical paste connector (DIP). SMT is generally mounted pinless or short-lead surface assembly components, the need to print solder paste on the circuit board, and then mounted through the chip machine, and then through the reflow soldering fixed devices. DIP welding is inline form of packaging devices, through the wave soldering or manual welding to fix the device.

SMT connectors over the furnace temperature is usually above 260 degrees, the duration of 3 to 5 seconds. Its structure is mainly composed of plastic parts and pins, plastic parts are generally used PA6T and PA9T material, these two materials have good high temperature performance. Chip connectors are widely used in highway camera equipment, stereo DC fans, intelligent electronic products, air conditioning, high-definition LCD TVs and notebook computers and other fields. Pin materials are common brass, bronze and phosphor bronze, etc., while the pin surface plating is mostly gold-plated (or semi-gold-plated) and tin-plated, the plating not only prevents oxidation, but also enhances the conductivity and signal transmission rate.

Methods to prevent the occurrence of false soldering SMT connectors:

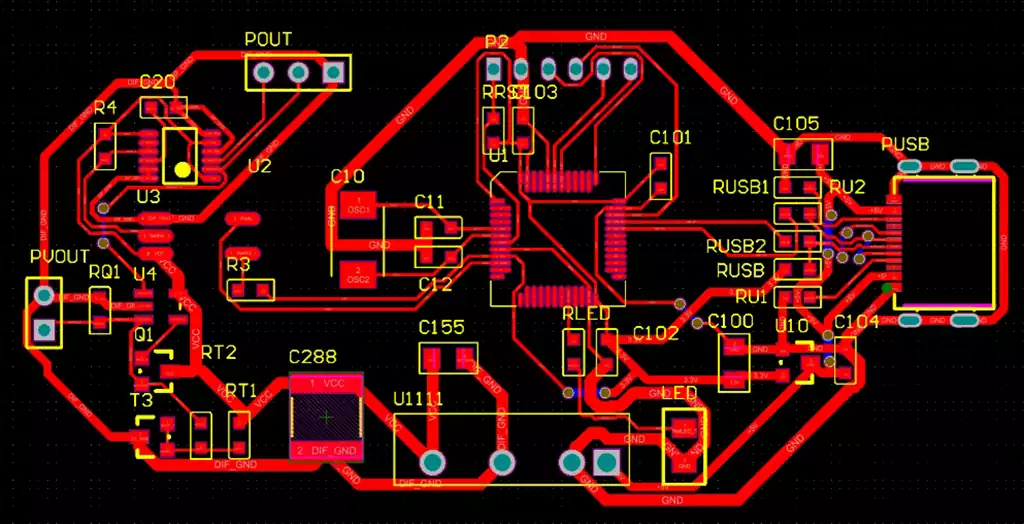

Reasonable design of pads and solder joints

Ensure that the pad size and shape of the smt connector is scientific and reasonable, while the location and size of the solder joints also need to be accurately designed to ensure that the solder joints can be fully and firmly welded to reduce the risk of soldering.

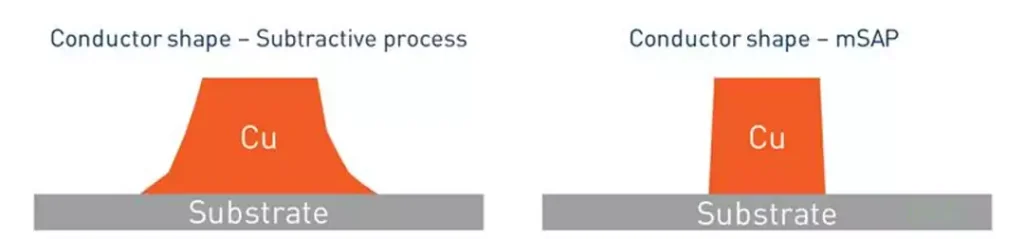

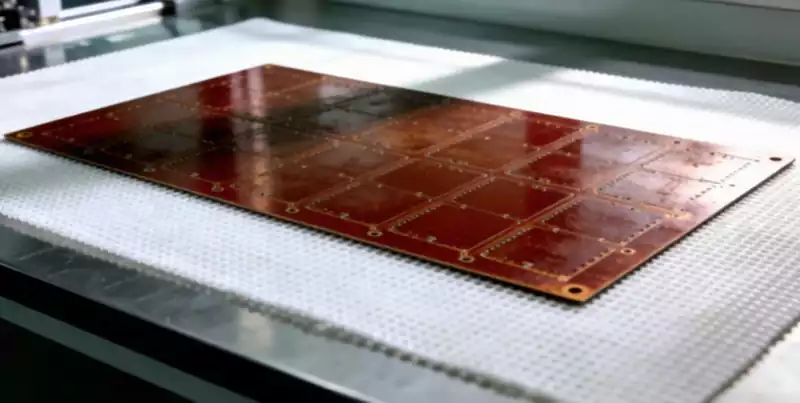

Optimize PCB manufacturing process

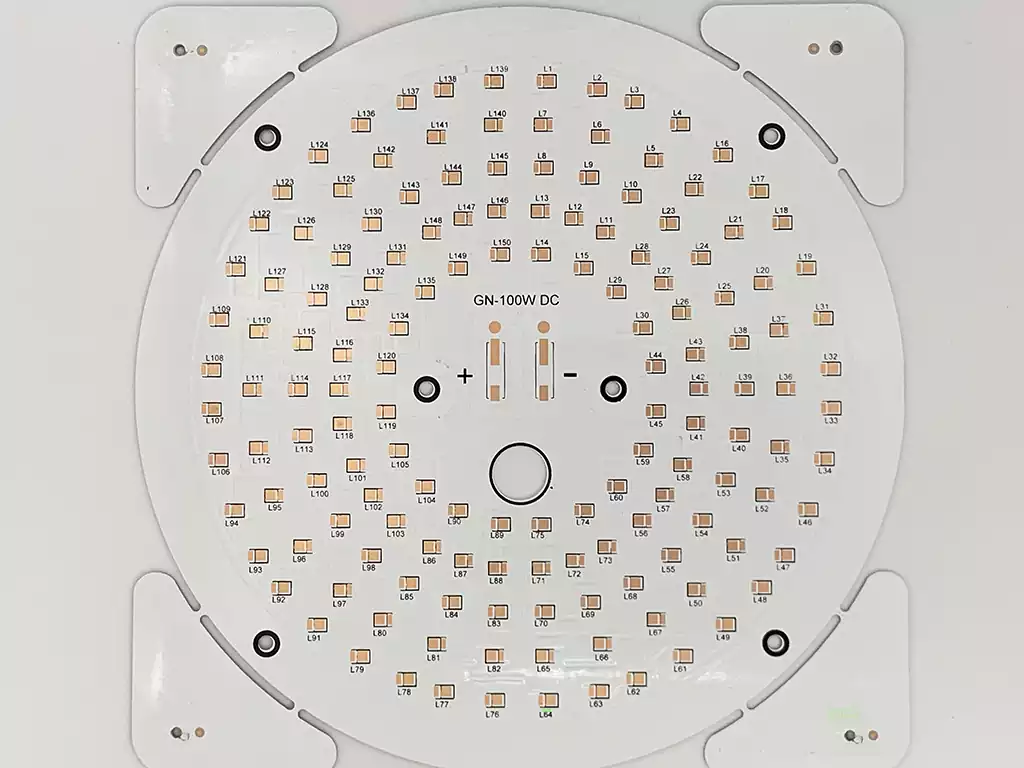

In the manufacture of PCBs need to strictly control the thickness of the board and material parameters, to ensure that the pad around the jaws have enough space to move. In addition, it is important to maintain the flatness of the PCB panel to avoid excessive or insufficient solder joints.

Precise control of the welding process parameters

When soldering SMT connectors, it is necessary to grasp the appropriate soldering temperature and duration. Too short a soldering time or insufficient temperature may result in solder joints not being fully integrated into the pads, resulting in false soldering; while too high a temperature or prolonged heating may damage the connector itself.

Selecting the right solder material

As different connector materials have an impact on soldering quality, the solder must meet the connector’s performance requirements, with good wettability and proper surface tension to ensure that the solder joints and pins can achieve close contact between.

Strict implementation of quality control measures

In the installation of smt connectors should be implemented strict quality inspection to ensure that the welding components without warping and can be accurately inserted into the connector. Soldering process should use the appropriate fixing tools and methods to avoid abnormal movement of components in the heating, so as to protect the quality of welding.

SMT connectors have the following advantages over TH connectors:

1.SMT connectors are faster to install, speeding up production efficiency.

2.SMT connectors can make the layout of the circuit board more compact, saving space.

3.SMT connectors have a higher degree of automation, which can reduce the disadvantages of manual operation.

TH connector

TH is the abbreviation of Through Hole Technology, which means through-hole mounting technology, meaning that holes can be punched in the circuit board and then the connector pins can be installed through the holes. Unlike SMT connectors, TH connectors do not require the use of adhesives or surface mounting equipment for mounting, and can simply be soldered.

TH connectors have the following advantages over SMT connectors:

- TH connector connection is more solid, in some scenarios can play a better connection effect.

- TH connector structure is more simple, easy to repair and replace.

- TH connector manufacturing cost is lower, suitable for small and medium-sized mass production.

With the development of electronic products in the direction of miniaturization, high-speed and automation, SMT connectors have gradually become the mainstream choice due to their advantages of fast installation, high automation and space saving; while TH connectors still have a place in specific needs by virtue of their firmness, reliability and easy maintenance.