EMI coating is a thin film made from materials that shield electromagnetic interference signals, capable of blocking the propagation of electromagnetic waves.

EMI coating is typically made from conductive materials and can be applied via adhesion or spraying to the external surfaces or internal structures of various electronic devices. EMI signal shielding coatings can be used to prevent electromagnetic waves from interfering with devices, protecting sensitive equipment from external interference and thereby enhancing the reliability and stability of the devices. This coating can be applied in fields such as telecommunications equipment, computers, automobiles, aerospace, and medical devices.

The working principle of EMI coating primarily relies on the propagation characteristics of electromagnetic waves within shielding materials. When electromagnetic waves encounter the shielding coating, they are reflected, absorbed, or attenuated, thereby reducing or eliminating their impact on surrounding electronic devices and personal safety. Specifically, EMI electromagnetic shielding coatings achieve shielding effects through the following two mechanisms:

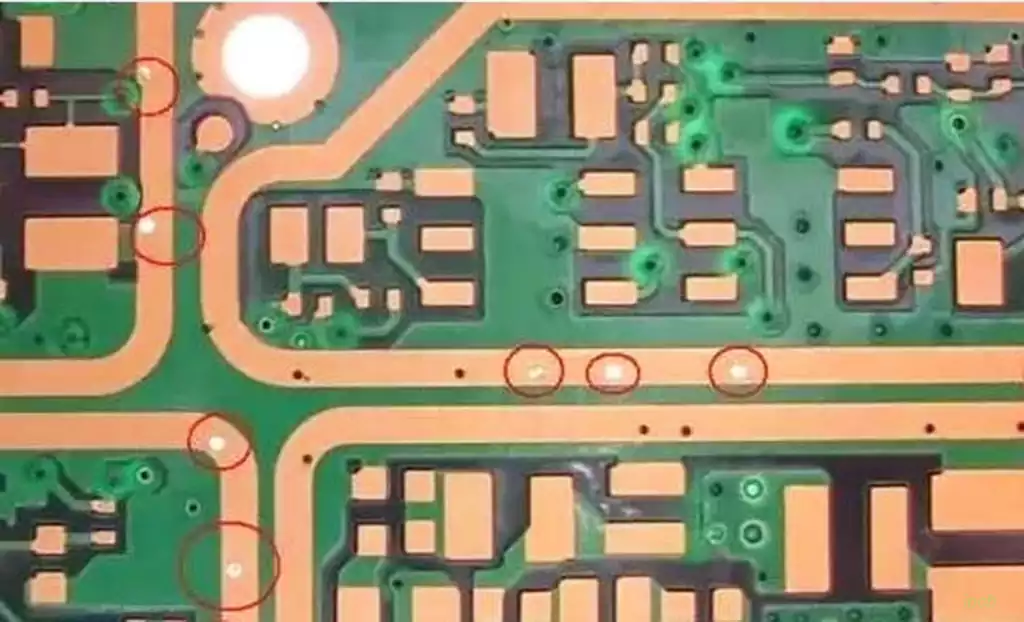

- Reflection: When electromagnetic waves encounter the surface of the shielding coating, they are reflected back due to the conductivity of the metallic material, thereby reducing interference with internal electronic components.

- Absorption and attenuation: Some electromagnetic waves that enter the shielding coating are absorbed within the material and converted into thermal energy, or gradually attenuated through multiple reflections and scattering processes, thereby reducing their ability to penetrate the shielding membrane.

EMI coating is typically made of conductive materials and can be applied by adhesion or spraying to the external surfaces or internal structures of various electronic devices. Their primary function is to prevent electromagnetic waves from interfering with the devices, protecting sensitive equipment from external electromagnetic interference, thereby enhancing the reliability and stability of the devices.

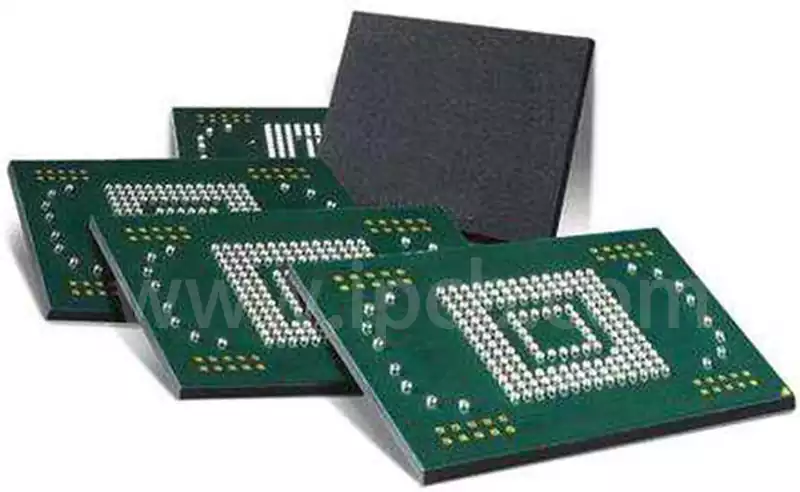

Sputtering targets play a crucial role in the application of EMI coating. Utilising sputtering coating technology, it is possible to produce thin films with excellent conductive properties and significant electromagnetic shielding effects, thereby providing effective electromagnetic interference protection for electronic devices.

Advantages of sputtering target materials in EMI coating applications

High controllability of film quality: Sputtering coating technology can produce uniform and dense conductive films with excellent conductivity and electromagnetic shielding performance. Additionally, the sputtering coating process allows precise control of film thickness and composition, thereby optimising the performance of EMI coating.

Diverse target material options: Sputtering target materials are available in a wide variety, including copper, chromium, silver, gold, stainless steel, aluminium, and silicon dioxide targets, among others, allowing for selection based on specific requirements. This enables EMI coating to meets specific requirements for conductivity, corrosion resistance, wear resistance, and other properties. For example, molybdenum and molybdenum alloy sputtering targets are widely used in electronics, solar cells, and glass coating applications due to their high melting point, excellent electrical and thermal conductivity, low thermal expansion coefficient, good corrosion resistance, and environmental friendliness. Tantalum and its compounds (such as tantalum carbide and tantalum nitride) are often used to prepare wear-resistant and corrosion-resistant coatings due to their high hardness, high melting point, and chemical inertness. Titanium target materials can provide hard coatings for wear-resistant and corrosion-resistant layers. Austenitic nickel-chromium stainless steel, as a sputtering target material, exhibits a high film deposition rate due to its paramagnetic properties, enabling the rapid formation of ferromagnetic ferritic stainless steel films with magnetic and electrical shielding effects, while also offering excellent weather resistance. Molybdenum sputtering target materials are used in displays to form extremely thin conductive coatings. Their primary advantage lies in their superior conductivity and minimal particle formation during the PVD process.

Sputtering coating technology also includes high-power pulsed magnetron sputtering (HiPIMS), which offers advantages such as high target material utilisation, high deposition rate, high plasma density, and good coating adhesion.

EMI coating, as a critical electromagnetic interference protection technology, play an indispensable role in modern electronic devices. With the continuous advancement of technology, the demand for EMI shielding coatings is growing, driving ongoing innovation in material selection and preparation techniques. The application of sputtering target materials in the EMI coating field provides important technical support for the preparation of high-performance electromagnetic shielding films.

Looking ahead, with the widespread adoption of technologies such as 5G, the Internet of Things, and artificial intelligence, electronic devices will become increasingly integrated and intelligent, leading to higher requirements for electromagnetic compatibility. EMI coating will continue to play a critical role, and through the development of new materials and processes, their shielding efficiency and application scope will be continuously enhanced. With the ongoing innovation of sputtering target materials and related technologies, EMI coating will provide stronger guarantees for the reliable operation of electronic devices, jointly building a safer and more efficient electromagnetic environment.