PCBA ion contamination refers to residual charged ion contaminants left behind during the manufacturing process of PCBA (Printed Circuit Board Assembly), primarily originating from flux, chemical cleaners, air humidity, electroplating, wave soldering, reflow soldering, and other process steps. These contaminants may cause issues such as electromigration and corrosion, thereby affecting circuit reliability.

Why Conduct Ion Contamination Testing

During PCBA production and assembly, the complexity of the entire production process, combined with factors such as materials and human processing, increases the risk of residual contamination on the PCB surface. Severe visual contamination can typically be detected through visual inspection. However, some minor contamination (such as trace amounts of rosin or cleaning solvent residues) cannot be immediately detected through visual or electrical testing. Such contamination often remains undetected until it causes operational abnormalities under specific working conditions over an extended period.

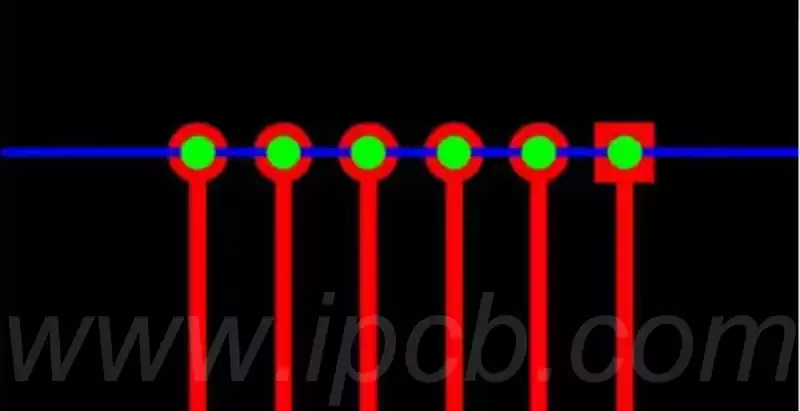

Therefore, as the electronics industry continues to evolve, the requirements for PCBA assembly processes are becoming increasingly stringent. The reliability and quality of electronic products ultimately depend on the reliability and quality of PCBA. Thus, the detection, analysis, and assessment of contamination levels are crucial for improving product quality and reliability. Contaminants on PCB boards primarily exist in the form of cations and anions, hence the term ‘ion contamination.’ The primary sources of ionic contamination include residual acids from raw materials and manufacturing processes. For example, acid washing during manufacturing can leave residual acidic ions (NO₃, SO₄), tin plating processes can leave residual chlorine (Cl), and PCB boards themselves can have residual bromine (Br). Therefore, the industry uses ionic contamination testing as a criterion for assessing PCB cleanliness.

PCBA Contamination

PCBA contamination refers to any surface contaminants that reduce the chemical, physical, or electrical performance of the PCBA to an unacceptable level, such as residues, impurities, inclusions, and adsorbed substances. The primary sources include the following:

- Oxidation or other contamination of PCBA components and the PCB itself.

- Residues generated by flux during the production process.

- Fingerprints, fixture marks, chain claw marks, high-temperature tape, hole-blocking adhesive, and dust generated during the soldering process.

- Dust, moisture, solvent vapours, smoke, particles, etc., in the workplace, as well as static-charged particles adhering to the PCBA.

The necessity of cleaning

Cleaning not only improves the appearance and electrical performance of the PCBA but also enhances the adhesion of protective coatings. Even in no-clean applications, cleaning is necessary to ensure the chemical safety of the PCB and the stability of the production line.

Hazards of Contamination

Contamination may pose potential risks to PCBA directly or indirectly, such as:

- Organic acids in residues may corrode PCBA.

- Ions in residues may cause short circuits due to electromigration when PCBA is energised, resulting from voltage differences between different potentials on the PCBA.

- Residues may affect the coating effect of protective coatings.

- Over time and with temperature changes, the coating may develop cracks and peeling, affecting reliability.

Purpose of Ion Contamination Testing:

Ensure product quality: promptly identify ion contamination issues to prevent defective products from entering the market.

Optimise production processes: adjust production procedures based on test results to reduce ion contamination risks.

Meet customer requirements: many customers have strict requirements for product ion contamination levels.

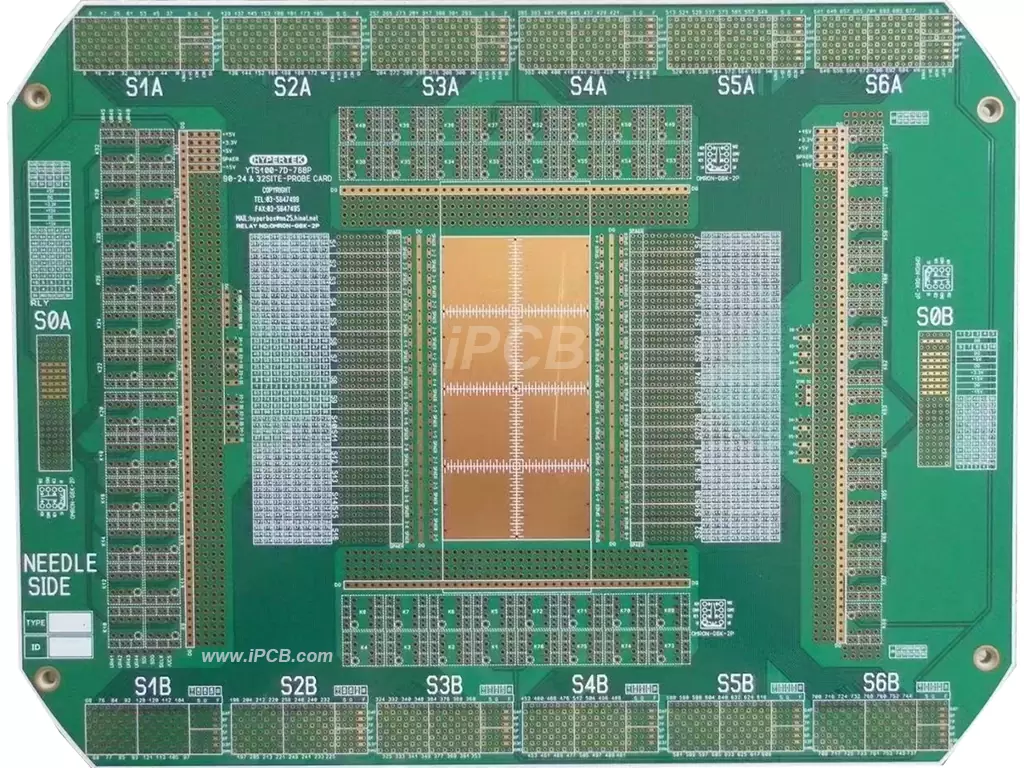

PCB Ion Contamination Testing:

A key indicator for measuring ion residue on electronic board surfaces, critical for the proper operation of circuit boards.

Common Reference Standards:

TRW204654 Cleanliness Specification Requirements for PCB/PCBA and Other Electronic/Electrical Assemblies

IPC TM-650 2.3.28B Ion Analysis of Circuit Boards – Ion Chromatography Method

IPC TM-650 2.3.25 Solvent Extraction Resistivity (ROSE) – Test Method

Ion contamination is the primary form of residue on PCBA surfaces. Through ion contamination testing, the cleanliness of PCBA can be effectively measured, and potential chemical, physical, and electrical performance risks can be identified and controlled, thereby enhancing overall product quality.

Therefore, conducting PCBA ion contamination testing is of critical importance. It not only ensures product quality, promptly identifies and prevents non-conforming products from entering the market; but also guides production process optimisation based on test results to reduce contamination risks; simultaneously, it meets customers’ stringent requirements for product ion contamination levels, complies with industry standards such as TRW204654 and IPC TM-650, and ultimately provides a solid foundation for the reliability and quality of electronic end-products.