In electronic manufacturing, circuit boards must be divided into distinct sections to meet the design requirements of various electronic products. Traditional mechanical cutting and punching techniques struggle to satisfy modern production standards. The advent of PCB laser depaneling machines has made this process efficient and precise, not only boosting production efficiency but also ensuring the quality of board separation. This lays the foundation for the performance and quality of electronic products.

The working principle of PCB laser depaneling machines involves directing a high-energy laser beam onto the circuit board. The heat from the laser beam rapidly vaporizes or melts the board material to achieve cutting. This non-contact cutting method avoids mechanical stress, making it particularly suitable for processing sensitive electronic components.

Common laser types include CO₂ lasers, fiber lasers, and UV lasers, each suited for different materials and applications. CO₂ lasers: Ideal for organic materials (e.g., FR-4, PI), offering fast cutting speeds with minimal heat-affected zones. Fiber lasers: Suitable for metal materials, offering high cutting precision with an even smaller heat-affected zone. Ultraviolet lasers: Ideal for precision processing like micro-hole drilling and cutting ultra-thin materials, featuring the smallest heat-affected zone.

FPC (Flexible Printed Circuit) and thin board separation typically employ two methods: punching and laser depaneling. Early FPC separation predominantly used the punching method, involving the creation of corresponding punching dies. The FPC was placed within the die, and the die was closed to punch and separate the FPC. High-end FPCs also require punching dies with vacuum leveling capabilities to ensure the flatness of the FPC on the die.

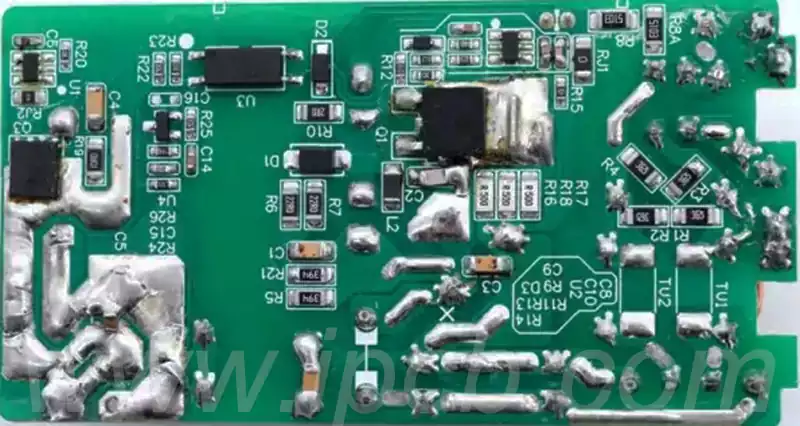

The working principle of punching dies is similar to scissors cutting paper. When the scissors blades become worn, they cannot cut the paper smoothly, generating squeezing and twisting forces. This leads to irregular cutting edges, and in severe cases, abnormal phenomena such as component solder joint cracking, PCB deformation, and wrinkling. For the punching process, dies must be cleaned, maintained, and serviced promptly. Adhesive residue, foreign objects, rust, oxidation, or chipped edges must not be present.

Punching is not recommended for rigid boards thicker than 0.5mm. Automating punching is challenging due to limited space between upper and lower dies, which hinders robotic access. Increasing the die clearance compromises clamping precision and is constrained by hydraulic cylinder stroke limitations.

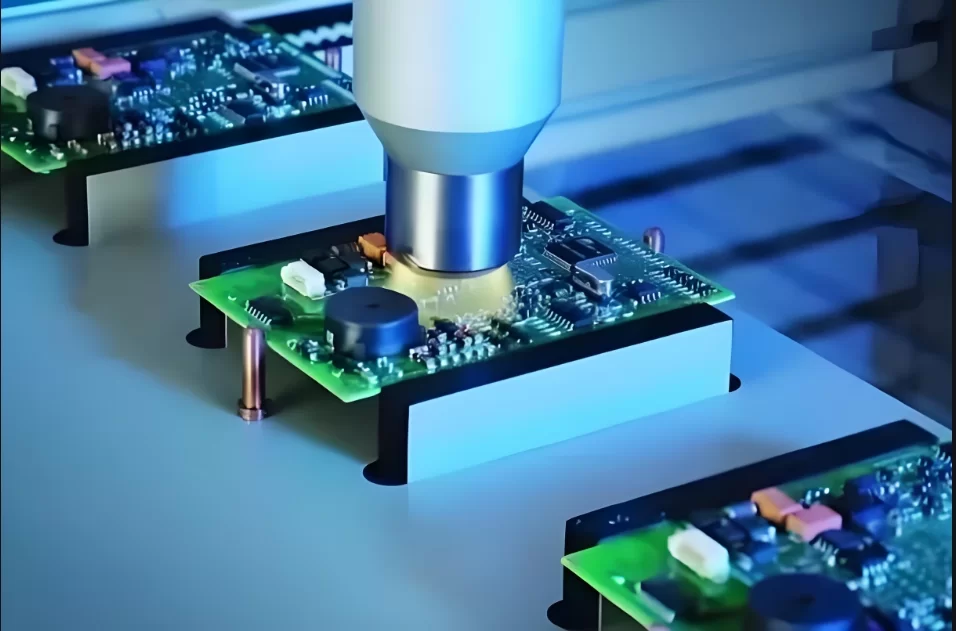

For high-volume FPC separation, laser cutting is a viable alternative. Laser depaneling enables fully automated inline processing: Welded FPCs are fed into the laser depaneling machine with magnetic carriers. The machine identifies fiducial marks to position the product, performs laser depaneling, and uses vacuum suction to remove stainless steel sheets. It then picks and places boards, trims edges, and automatically recovers carriers. Laser depaneling technology is mature and widely adopted, eliminating the need for depaneling fixtures and finding extensive application in FPC depaneling.

Note that CO₂ lasers emit thermal light, and the heat generated during separation can cause carbonization. Under certain conditions, this may lead to leakage. Since FPC separation requires low power, UV laser separation is generally recommended. UV light is cold, minimizing carbonization during separation and effectively preventing quality defects caused by carbonization. Laser depaneling offers high efficiency, superior quality, rapid changeovers, and low operating costs. It enables fully automated, unmanned production, making it the preferred solution for FPC depaneling.

Advantages of PCB Laser Depaneling

Compared to traditional mechanical cutting methods, PCB laser depaneling provides multiple advantages:

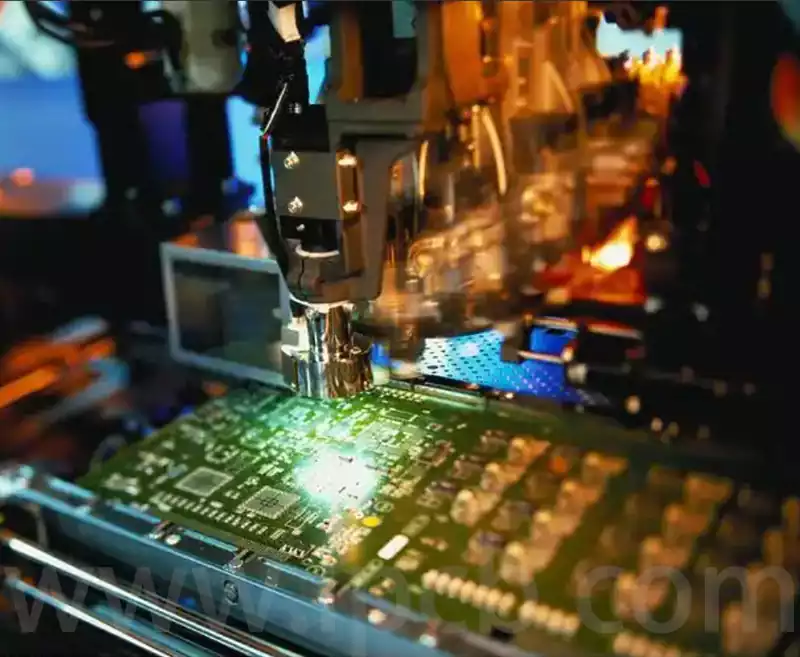

High Precision: Laser cutting requires no contact with the workpiece, producing clean edges free of burrs and achieving micron-level precision.

High Efficiency: The laser cutting process is rapid and continuous, making it suitable for mass production without the need for complex mold preparation.

Pollution-Free: Laser cutting involves no tool wear, avoiding chemical contamination and the hassle of tool replacement.

High Flexibility: Laser cutters can be freely programmed according to design drawings, flexibly adapting to the cutting needs of PCBs of different sizes, shapes, and structures.

Precautions for PCB Laser Depaneling

Several critical factors require special attention when using a PCB laser depaneling machine:

Cutting Parameter Settings: Parameters such as laser power, cutting speed, focal length, and frequency must be precisely adjusted according to the specific PCB material and thickness. The Dazhou Yueming Laser PCB depaneling machine features an intelligent control system that automatically regulates these parameters to achieve optimal cutting results.

Material Type and Thickness: Different PCB types (e.g., single-sided, double-sided, multilayer boards) have distinct laser cutting requirements. Dazhuo Yueming Laser PCB depaneling machines handle varying PCB thicknesses with high-precision laser control to meet diverse processing needs.

Cutting Quality Control: During cutting, special attention must be paid to preventing material deformation or copper layer detachment caused by overheating. The high-precision positioning and temperature control technology of the Dazhuo Yueming Laser PCB Depaneling Machine effectively minimizes these risks.

Fume Emission: Laser cutting generates significant fumes that may impact equipment and environmental health. Therefore, ensuring an effective fume extraction and filtration system is essential.

Post-Processing: While laser cutting delivers precise edges, subsequent surface treatments like cleaning or deburring may be required in certain cases. These steps further enhance PCB quality.

PCB laser depaneling technology, with its advantages of high precision, efficiency, pollution-free operation, and flexibility, is progressively replacing traditional mechanical cutting and punching methods. It has become an indispensable process in modern electronics manufacturing. Not only does it significantly boost production efficiency, but more importantly, its non-contact cutting method effectively avoids mechanical stress, ensuring superior board separation quality. This lays a solid foundation for the outstanding performance and reliability of various electronic products. Particularly when handling FPCs and thin boards, laser depaneling demonstrates distinct advantages through automation and adaptability to precision processing.