FR1 pcb is constructed from glass fiber-reinforced epoxy resin laminates. FR1 PCBs are rigid, flat materials composed of thin copper layers on a non-conductive phenolic resin substrate.

FR1, fully known as Flame Retardant 1, is a PC film with high insulation and flame-retardant properties. This material not only exhibits excellent flame resistance but also possesses good temperature resistance. FR1 typically appears milky white, with one side glossy and the other matte. Its characteristics of easy folding, bending, and processing into shapes provide high flexibility during circuit board manufacturing.

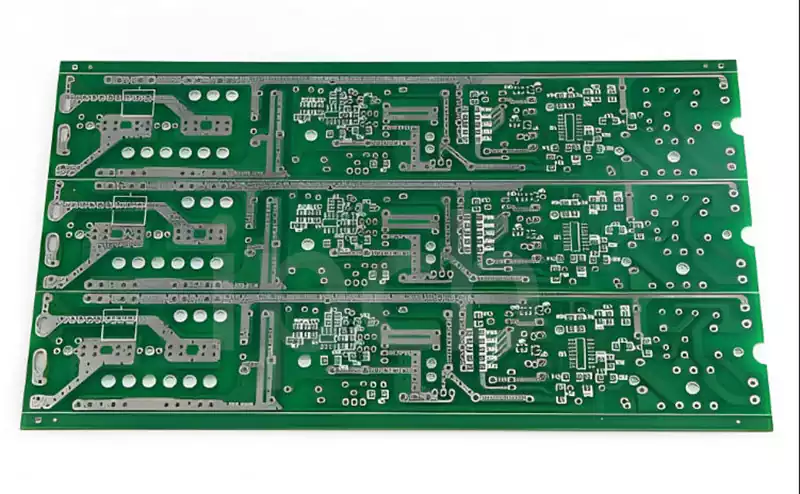

Due to its high flame retardancy and eco-friendly properties (compliant with ROHS regulations), FR1 is widely used in power supplies, push buttons, PC boards, and insulation for business machines. Additionally, FR1 is frequently used for printed circuit board insulation, display panels, televisions/monitors, and internal insulation/shielding in appliances. FR1 boards are commonly employed in electronics due to their rapid, easy mass production. They are typically manufactured via stamping or etching, with the copper surface chemically coated with insulating material.

FR1 PCB offers the following advantages:

Mechanical Strength

FR1 circuits utilize mechanical drilling to position components. This ensures the highest precision in circuit and PCB component placement.

Cost-Effectiveness

FR1 PCB boards are manufactured using paperboard. They are low-cost and easy to assemble. Consequently, manufacturing and labor costs are reduced compared to other PCB board production methods.

Compact Size

FR1 PCB copper traces can accommodate numerous components in minimal space. Thus, the circuit does not become bulky. The compact structure of FR1 circuits enables efficient manufacturing of small devices.

High Performance

FR1 delivers long-term efficiency without compromising performance. It also exhibits very low electrical noise. Its quality and reliability ensure customer satisfaction.

FR1 pcb plays a vital role in many low-cost, low-complexity electronic products due to their high flame retardancy, eco-friendly properties, and cost-effectiveness. Despite limitations in moisture resistance, thermal expansion coefficient, and electrical properties, FR1 can still meet specific application requirements through targeted design and manufacturing process optimization. As electronic manufacturing technology advances, FR1 will continue to deliver unique value as an economical substrate in cost-sensitive applications with moderate performance demands.

Environmentally Friendly

FR1 circuit boards are considered eco-friendly PCBs. FR1 PCB is halogen-free circuit board. Additionally, they contain no harmful elements that may adversely affect the environment.

Simultaneously, they are safe for users of devices incorporating FR1 PCBs.

Differences Between FR1 PCB and FR4 PCB

Material Composition

FR1 PCB: Constructed from paper core material impregnated with phenolic resin, featuring a softer texture and lower cost.

FR4 PCB: Constructed from glass fiber cloth impregnated with epoxy resin, offering high mechanical strength, superior heat resistance, and enhanced insulation properties.

Performance Characteristics

FR1 PCB: Poor moisture resistance, higher thermal expansion coefficient, and relatively weaker electrical performance. Suitable for single-sided boards with low performance requirements.

FR4 PCB: Excellent mechanical strength, heat resistance, and electrical stability. Ideal for multilayer boards and high-frequency circuits.

Application Scenarios

FR1 PCB offers the following advantages:

Mechanical Strength

FR1 circuits utilize mechanical drilling to position components. This ensures the highest precision in circuit and PCB component placement.

Cost-Effectiveness

FR1 PCB boards are manufactured using paperboard. They are low-cost and easy to assemble. Consequently, manufacturing and labor costs are reduced compared to other PCB board production methods.

Compact Size

FR1 PCB copper traces can accommodate numerous components in minimal space. Thus, the circuit does not become bulky. The compact structure of FR1 circuits enables efficient manufacturing of small devices.

High Performance

FR1 delivers long-term efficiency without compromising performance. It also exhibits very low electrical noise. Its quality and reliability ensure customer satisfaction.

FR1 pcb plays a vital role in many low-cost, low-complexity electronic products due to their high flame retardancy, eco-friendly properties, and cost-effectiveness. Despite limitations in moisture resistance, thermal expansion coefficient, and electrical properties, FR1 can still meet specific application requirements through targeted design and manufacturing process optimization. As electronic manufacturing technology advances, FR1 will continue to deliver unique value as an economical substrate in cost-sensitive applications with moderate performance demands.

Environmentally Friendly

FR1 circuit boards are considered eco-friendly PCBs. FR1 PCBs are halogen-free circuit boards. Additionally, they contain no harmful elements that may adversely affect the environment.

Simultaneously, they are safe for users of devices incorporating FR1 PCBs.

Differences Between FR1 PCB and FR4 PCB

Material Composition

FR1 PCB: Constructed from paper core material impregnated with phenolic resin, featuring a softer texture and lower cost.

FR4 PCB: Constructed from glass fiber cloth impregnated with epoxy resin, offering high mechanical strength, superior heat resistance, and enhanced insulation properties.

Performance Characteristics

FR1 PCB: Poor moisture resistance, higher thermal expansion coefficient, and relatively weaker electrical performance. Suitable for single-sided boards with low performance requirements.

FR4 PCB: Excellent mechanical strength, heat resistance, and electrical stability. Ideal for multilayer boards and high-frequency circuits.

Application Scenarios

FR1 PCB: Commonly used in low-cost, low-complexity electronics such as simple remote controls and white goods.

FR4 PCB: Widely applied in consumer electronics, communication equipment, industrial control systems, and other fields, particularly suited for scenarios demanding high reliability.

Cost and Processing Difficulty

FR1 PCB: Lower cost but prone to deformation during processing, requiring careful process control.

FR4 PCB: Higher cost but offers high processing precision, capable of meeting complex circuit design requirements.

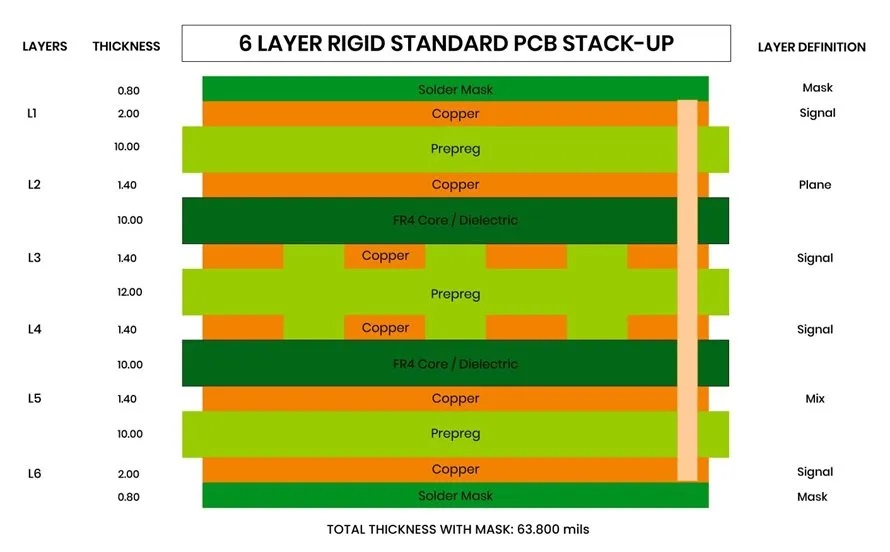

Number of Layers

FR1 is limited to single-layer circuits, while FR4 supports multi-layer PCBs with up to eight layers. FR4 is also the most suitable FR material for multi-layer PCBs.

FR1 vs. FR2

Glass Transition Temperature (Tg): FR1 has a Tg of 130°C, while FR2 has a Tg of 105°C.

Cost and Applications: FR1 and FR2 share similar costs and applications. Both are low-cost PCB materials.

FR1 vs. CEM-1

Substrate Material: FR1 substrates are made from phenolic resin, while CEM-1 substrates utilize woven glass fabric.

Number of Layers: FR1 is exclusively used for single-layer PCBs, whereas CEM-3 (with properties similar to CEM-1) can be used for multilayer PCBs.

FR1 vs. Metal Core PCB (MCPCB)

Laminate Material: FR1 is laminated from paper layers, while MCPCB laminates are composed of thick metal.

Conductivity and Heat Transfer: FR1 PCB exhibits poor electrical conductivity, whereas MCPCBs possess excellent conductivity and superior heat transfer efficiency. FR1 is unsuitable for applications requiring effective heat dissipation, as accumulated heat can exceed its tolerance and cause damage.

FR1 PCB plays a vital role in numerous low-cost, low-complexity electronic products due to their high flame retardancy, eco-friendly properties, and cost-effectiveness. Despite limitations in moisture resistance, thermal expansion coefficient, and electrical performance, FR1 can still meet specific application requirements through targeted design and manufacturing process optimization. As electronic manufacturing technologies advance, FR1 will continue to deliver unique value as an economical substrate in cost-sensitive applications with moderate performance demands.: Commonly used in low-cost, low-complexity electronics such as simple remote controls and white goods.

FR4 PCB: Widely applied in consumer electronics, communication equipment, industrial control systems, and other fields, particularly suited for scenarios demanding high reliability.

Cost and Processing Difficulty

FR1 PCB: Lower cost but prone to deformation during processing, requiring careful process control.

FR4 PCB: Higher cost but offers high processing precision, capable of meeting complex circuit design requirements.

Number of Layers

FR1 is limited to single-layer circuits, while FR4 supports multi-layer PCBs with up to eight layers. FR4 is also the most suitable FR material for multi-layer PCBs.

FR1 vs. FR2

Glass Transition Temperature (Tg): FR1 has a Tg of 130°C, while FR2 has a Tg of 105°C.

Cost and Applications: FR1 and FR2 share similar costs and applications. Both are low-cost PCB materials.

FR1 vs. CEM-1

Substrate Material: FR1 substrates are made from phenolic resin, while CEM-1 substrates utilize woven glass fabric.

Number of Layers: FR1 is exclusively used for single-layer PCBs, whereas CEM-3 (with properties similar to CEM-1) can be used for multilayer PCBs.

FR1 vs. Metal Core PCB (MCPCB)

Laminate Material: FR1 is laminated from paper layers, while MCPCB laminates are composed of thick metal.

Conductivity and Heat Transfer: FR1 PCB exhibits poor electrical conductivity, whereas MCPCBs possess excellent conductivity and superior heat transfer efficiency. FR1 is unsuitable for applications requiring effective heat dissipation, as accumulated heat can exceed its tolerance and cause damage.

FR1 PCB plays a vital role in numerous low-cost, low-complexity electronic products due to their high flame retardancy, eco-friendly properties, and cost-effectiveness. Despite limitations in moisture resistance, thermal expansion coefficient, and electrical performance, FR1 can still meet specific application requirements through targeted design and manufacturing process optimization. As electronic manufacturing technologies advance, FR1 will continue to deliver unique value as an economical substrate in cost-sensitive applications with moderate performance demands.