Definition and Function of a PCB Board Transformer

In modern electronics manufacturing, the term “PCB board transformer” is a common yet often misunderstood concept. It typically refers to a transformer device mounted on a printed circuit board (PCB). This encompasses both the physical device itself and the circuit layout and engineering coordination surrounding it within the PCB design. Unlike traditional large power transformers, transformers used on PCBs are more targeted towards electronic circuit applications. Their primary tasks are voltage conversion, current isolation, and signal coupling, ensuring safe and stable circuit operation.

The role of a PCB transformer can be understood from three perspectives. First, it is the most critical voltage regulation component in the power supply system, converting the input voltage to the stable voltage required by the target circuit. For example, household appliances often need to convert 220V mains power to a low-voltage supply of 5V or 12V, which is essential for small transformers on the PCB. Second, it is a crucial means of electrical isolation, effectively preventing direct contact between high-voltage and low-voltage circuits, protecting users and sensitive components. Third, they also play an irreplaceable role in signal transmission and electromagnetic compatibility. In particular, signal transformers ensure data integrity and interference resistance in communications and data processing equipment.

Compared to traditional large iron-core transformers, PCB transformers are small, lightweight, easy to install, and highly integrated with circuits. With the increasing miniaturization and high integration of electronic devices, these transformers have become indispensable components in modern circuit design. In particular, in fields such as switching power supplies, LED driver circuits, network communication modules, and medical devices, the use of PCB transformers not only improves circuit efficiency but also significantly reduces overall manufacturing costs.

From an industry development perspective, the existence of PCB transformers has transformed the PCB into more than just a carrier, but a system that actively participates in power management and signal processing. They not only provide energy transmission and isolation at the hardware level but also lay the foundation for reliability and safety at the system level. Therefore, understanding the concept and function of PCB transformers is essential knowledge for engineers, procurement personnel, and even beginners entering the electronics industry.

Analysis of the Basic Working Principle of a PCB Board Transformer

To understand the working principle of a PCB board transformer, we must first begin with the fundamental law of electromagnetic induction. The core principle of any transformer is Faraday’s law of electromagnetic induction, which states that when an alternating current flows through a coil, an alternating magnetic field is generated around it. This magnetic field induces an electromotive force in a neighboring coil. PCB transformers utilize this physical phenomenon to convert voltage and current.

A typical PCB transformer consists of a primary winding, a secondary winding, and a magnetic core. The primary winding receives an input voltage. When AC current flows through the primary winding, an alternating magnetic flux is generated in the core. This change in magnetic flux induces a voltage in the secondary winding. By adjusting the turns ratio of the windings, the voltage can be increased or decreased. For example, if the turns ratio of the primary winding to the secondary winding is 10:1, a 220V input voltage will result in an output voltage of approximately 22V. This basic principle applies to all transformers, whether large power transformers or small transformers mounted on PCBs.

PCB transformers typically operate in three main modes:

Voltage conversion mode: This is the most straightforward application, used to adjust the input voltage to the level required by the circuit. For example, in switching power supply modules, transformers can both reduce high-voltage mains voltage to low-voltage DC and perform voltage conversion in DC-DC circuits.

Electrical isolation mode: When a circuit requires high- and low-voltage separation, PCB transformers achieve energy transfer through magnetic field coupling, without direct electrical connection between the two sides. This protects the safety of the low-voltage circuit while also preventing interference from high-voltage sources. This requirement is particularly stringent in medical equipment and power adapters.

Signal coupling mode: In communications or data transmission, small signal transformers can block DC components and transmit AC signals, while also improving interference immunity. For example, network transformers commonly used in Ethernet interfaces are typical signal coupling devices on PCBs.

It is worth noting that the core material of a PCB transformer has a decisive influence on its performance. Common types include ferrite and silicon steel. Ferrite is widely used in high-frequency circuits due to its low loss and excellent frequency characteristics. Silicon steel sheets, on the other hand, are primarily used in low-frequency, high-power transformers. In small electronic devices, most PCB transformers use ferrite cores to accommodate the tens or even hundreds of kilohertz operating frequencies of switching power supplies.

In addition, the design of the windings directly impacts the transformer’s efficiency and stability. Due to limited PCB space, windings often utilize fine enameled wire, with strict control over the insulation thickness and layout to ensure the transformer can withstand high voltages without excessively increasing its size. For high-frequency applications, multi-strand Litz wire is also used to reduce losses caused by the skin effect.

In summary, the operating principle of a PCB transformer is more than simply converting input voltage into output voltage; it integrates multidisciplinary knowledge from electromagnetics, materials science, and circuit design. Only by thoroughly understanding its fundamental mechanisms can engineers effectively design and implement it, avoiding problems such as overheating, inefficiency, and electrical unsafety.

Common Types and Applications of PCB Board Transformers

In actual electronics manufacturing and applications, PCB board transformers do not come in a single form factor; rather, they vary depending on their intended use, operating frequency, power level, and circuit requirements. Different types of PCB transformers perform diverse tasks, ranging from basic voltage conversion to complex signal coupling to high-reliability isolation in specialized equipment. Each type has a direct impact on the overall performance of the circuit.

Power Transformer

Power transformers are the most common type of transformer on PCBs, primarily used to convert high AC voltage to the low voltage required by circuits. They are commonly found in devices such as switching power supplies, adapters, and LED drivers. These transformers emphasize efficiency and stability, typically using ferrite cores to accommodate high-frequency operation. With the trend toward miniaturization, power transformer designs are becoming increasingly compact, requiring them to meet energy transmission requirements while also balancing heat dissipation and safety.

Isolation Transformer

The primary function of an isolation transformer is to provide electrical isolation, preventing high voltage from directly entering low-voltage control circuits. They are particularly common in medical devices, industrial control systems, and laboratory measurement equipment. For example, in medical monitoring equipment, without a high-quality isolation transformer, patients could be exposed to the risk of electric shock. The design of such transformers focuses on insulation ratings and safety certifications, such as compliance with UL or IEC standards for withstand voltage.

Signal Transformers

Signal transformers are not responsible for high-power energy conversion, but rather for signal transmission and processing. They transmit AC signals through magnetic coupling while isolating DC components. They are commonly found in audio equipment, communication modules, and network interfaces. Small network transformers in Ethernet interfaces are a typical example. They enhance signal integrity and improve interference immunity, thereby ensuring reliable data transmission. In high-frequency communications, signal transformers are also crucial for circuit impedance matching.

High-Frequency Transformers

With the widespread use of switching power supplies and RF circuits, high-frequency transformers have become key components on PCBs. These transformers operate in the frequency range of tens of kilohertz to several megahertz, placing extremely high demands on materials and winding structures. High-frequency transformers often use ferrite cores and stranded wire to reduce losses and improve efficiency. They are commonly found in laptop power supplies, chargers, and communication base station equipment.

Special Application Transformers

In addition to the mainstream types mentioned above, there are also some PCB transformers designed for specialized scenarios. For example:

Pulse transformers: Used in switching circuits to transmit control pulse signals, requiring high waveform fidelity.

Audio transformers: Commonly found in audio and recording equipment, they achieve channel isolation and signal amplification.

Current transformers: Although relatively small, they are indispensable for circuit protection and energy consumption monitoring.

Application Overview

Consumer Electronics: Mobile phone chargers, laptop power adapters, TVs, etc.

Industrial Control: Automation equipment, PLC modules, sensor interfaces.

Medical Equipment: ECG monitors, ventilators, imaging equipment, etc.

Communication Networks: Routers, switches, base station equipment.

New Energy and Automotive Electronics: Electric vehicle charging stations, inverters, battery management systems.

As can be seen, PCB board transformers have applications across nearly every electronics industry. From consumer products to industrial control, from information communications to new energy, they play a vital role. For this reason, different types of transformers have their own design priorities. For example, power transformers prioritize efficiency, isolation transformers emphasize safety, and signal transformers prioritize signal integrity. Engineers must make the right choice based on specific application requirements.

Key Points in PCB Board Transformer Design and Manufacturing

In the electronics industry, the performance of a PCB board transformer directly determines the safety and stability of the entire circuit system. Therefore, design and manufacturing is more than just a simple parameter calculation; it is a complex process that requires comprehensive consideration of electrical performance, mechanical structure, heat dissipation, material properties, and production processes. The following discusses several key dimensions.

Electrical Parameter Design

When designing a transformer, the electrical specifications must be clearly defined, including the input voltage range, output voltage, power requirements, and operating frequency. The turns ratio of the winding is determined by the voltage conversion ratio, but the number of turns is not a haphazard setting; magnetic flux density and efficiency must also be considered. If the core saturates, the transformer will not function properly and may even overheat and damage. High-frequency circuits are particularly important to avoid excessive core losses, so calculating the matching of frequency and magnetic flux is particularly important.

Core and Material Selection

The core is the “heart” of the transformer. Common materials include ferrite, silicon steel sheet, and nanocrystalline alloys.

Ferrite cores: Suitable for high-frequency circuits, with low loss, are commonly used in switching power supplies and signal transmission.

Silicon steel sheet cores: Suitable for low-frequency, high-power applications, such as industrial control power supplies.

Nanocrystalline cores: Offer excellent high-frequency characteristics and low loss, but are more expensive and are typically used in high-end equipment.

In addition to the core, the wire used for the windings also requires careful selection. Ordinary enameled copper wire is sufficient for most applications, while Litz wire is often used at high frequencies to reduce losses caused by the skin effect. Insulation materials are also critical, impacting safety and long-term reliability. High-grade insulation not only prevents breakdown but also withstands high temperatures and humidity.

Layout and Mechanical Design

When integrating a transformer on a PCB, space is often limited. Therefore, the mechanical design must strike a balance between compactness and safety. Too close a gap can lead to poor heat dissipation and shorten lifespan, while too large a gap increases cost and board space. Designers must consider the following:

Creeping distance and electrical clearance: Ensure physical isolation between high-voltage and low-voltage components to prevent breakdown.

Heat dissipation paths: Reduce temperature rise by thickening the copper foil, adding heat dissipation holes, or using external heat sinks.

Shielding measures: In some high-frequency applications, electromagnetic shielding can be added to reduce interference.

Process and Manufacturing

Consistency in the manufacturing process determines the quality stability of mass production. Common process challenges include:

Tight and neat winding arrangement to avoid the risk of breakdown caused by localized electric field concentration.

Thorough varnishing and curing processes affect withstand voltage and heat dissipation.

Precise core assembly; excessive or insufficient air gaps can affect magnetic flux efficiency.

Furthermore, manufacturers must have rigorous quality testing capabilities, such as voltage withstand testing, temperature rise testing, and frequency response testing, to ensure that each transformer meets design specifications.

Safety and Standard Certification

Different application scenarios have strict safety standards requirements. Medical devices are required to comply with IEC 60601, industrial equipment must comply with IEC 61558, and consumer electronics typically refer to UL/CE standards. This not only impacts product marketability but also user safety. Designers must consider these standards from the outset, rather than as a retrofit after the product is completed.

Cost and Manufacturability

In actual production, cost control is equally important. Excessive pursuit of high-performance materials will significantly increase prices, hindering market competitiveness; however, blindly cutting costs will compromise quality and lifespan. Excellent design engineers often strike a balance between performance, reliability, and cost. For example, for ordinary consumer electronics, ferrite cores and automated winding processes can be used, while high-end medical devices may require higher levels of insulation and stricter process controls.

In summary, the design and manufacture of PCB board transformers is a combination of science and art. It requires engineers to have a deep understanding of electromagnetics theory and a detailed understanding of materials science and manufacturing processes. Only by effectively integrating design, materials, processes, safety, and cost can reliable and competitive products be produced.

PCB Board Transformer Performance Testing and Quality Assessment

In the electronics industry, PCB board transformers are not isolated components but crucial components for the reliability of the entire circuit. Even with a well-designed design and high-quality materials, problems can arise during use if they are not rigorously tested and evaluated. Therefore, performance testing and quality assessment are critical steps to ensure the long-term and stable operation of transformers.

Electrical Performance Testing

Electrical parameters are the most fundamental performance indicators of transformers. Common tests include:

No-load loss test: This measures energy consumption without load to assess efficiency. High loss indicates problems with the core or winding design.

Load test: This tests the output voltage and current stability and efficiency under rated load and overload conditions.

Voltage ratio test: This verifies that the winding turns ratio is consistent with the design to avoid voltage conversion deviation.

DC resistance test: This verifies that the winding wires are uniform and contains no broken strands or poor solder joints.

Insulation and withstand voltage test

As the isolation component in the circuit, insulation is the lifeblood of the transformer. Test items include:

Hi-Pot Test: Testing insulation materials under high voltage checks for material breakdown to ensure safe isolation between high and low voltages.

Insulation resistance testing: Verifies insulation performance meets standards by measuring the resistance between different windings.

Creep distance and clearance verification: Verifies compliance with international standards based on the actual PCB layout.

Thermal performance and environmental adaptability testing

Transformers generate heat during operation. Excessive temperature rise may cause insulation degradation and shorten service life. Common tests include:

Temperature rise test: Measure temperature changes in the windings and core during long-term operation under rated load.

Thermal shock test: Repeatedly cycles between high and low temperatures to test the thermal stability of the material.

Damp heat test: Operates in high temperature and high humidity environments to verify the durability of insulation and metal materials.

High-frequency and signal performance testing

For high-frequency and signal transformers, circuit performance depends not only on voltage and current but also on frequency characteristics. Common tests include:

Frequency response: Verifies stable transmission within the operating frequency band.

Coupling coefficient test: Measures signal transmission efficiency. A low coupling coefficient results in energy loss. Impedance matching testing: This is particularly important in communications and data transmission scenarios, impacting signal integrity and anti-interference performance.

Reliability and Lifespan Assessment

In addition to single-shot performance testing, long-term reliability assessment is also essential.

Lifespan Prediction Testing: This uses high-temperature accelerated aging experiments to predict actual service life.

Shock and Vibration Testing: This simulates the mechanical stresses experienced during transportation and use to verify structural robustness.

Failure Mode Analysis (FMEA): This analyzes failure modes to predict potential risks and optimize designs.

Standards and Certification

Different application areas have different testing standards and certification systems.

Consumer Electronics: UL, CE, RoHS, etc.

Industrial and Medical: IEC 61558, IEC 60601, etc.

Communications and Networking: IEEE-related interface standards.

Obtaining these certifications not only ensures product safety and stable performance but also helps companies successfully enter the international market.

Overall, the performance testing and quality assessment of PCB board transformers is a comprehensive system engineering process, covering everything from electrical parameters, insulation capacity, thermal stability, to reliability and lifespan. Only products that undergo rigorous testing can truly meet the diverse application requirements of consumer electronics, industrial control, and medical equipment.

Future Development Trends and Industry Opportunities of PCB Board Transformers

With the rapid development and technological advancements of the electronics industry, the role of PCB board transformers is constantly evolving. Their design, manufacturing, and application will face new opportunities and challenges, while also providing companies with a broad market space.

Miniaturization and High Integration Trends

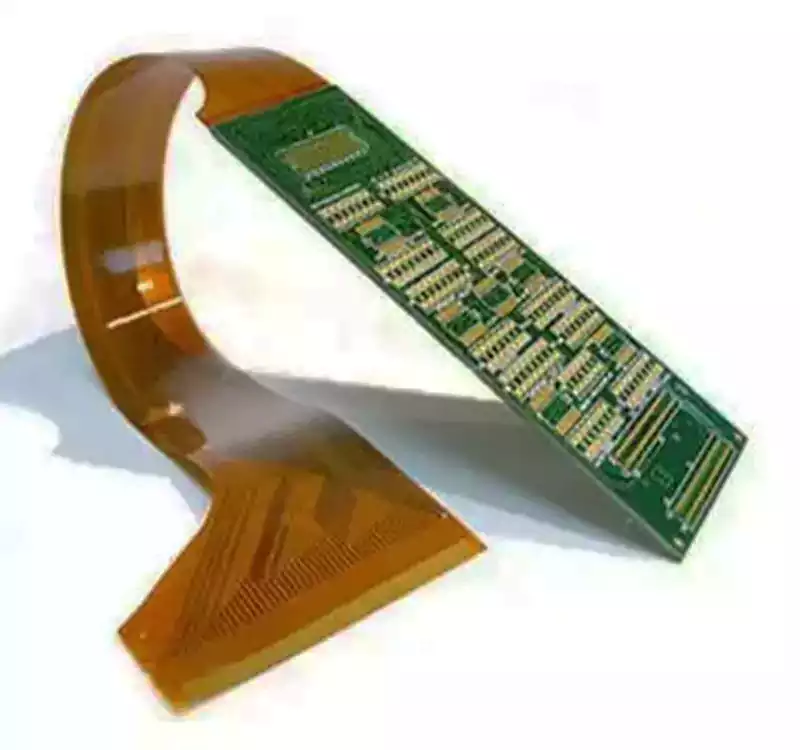

Modern electronic devices are increasingly pursuing thinner, lighter, and shorter designs. From smartphones and tablets to wearables, these devices are placing higher demands on the size and performance of PCB board transformers. Future PCB transformers will be even more miniaturized and densely integrated, requiring them to not only achieve voltage conversion and isolation within limited space but also maintain heat dissipation and signal integrity. This is driving the use of multilayer PCB designs, high-frequency transformer technology, and new magnetic core materials.

High-Frequency and High-Efficiency Development

To meet the demands of switching power supplies, communications, and new energy vehicles, PCB transformers will increasingly utilize high-frequency technology. High-frequency operation can reduce core size and improve energy efficiency, but it also places higher demands on core loss, winding design, and EMI (electromagnetic interference) control. This means engineers must consider efficiency, thermal management, and interference immunity during design.

New Materials and Process Innovation

As electronic devices advance toward high performance and high reliability, new core materials, wire insulation materials, and PCB manufacturing processes have become key research and development priorities. For example, nanocrystalline alloy cores and high-temperature insulation materials can significantly reduce energy consumption and improve long-term reliability. Furthermore, the application of automated winding and high-precision assembly processes makes mass production of miniaturized PCB transformers more feasible and stable.

Intelligent and Automated Testing

Future PCB transformer production will increasingly rely on intelligent equipment and automated testing technologies. For example, AI-assisted electrical performance analysis, thermal simulation optimization, and online automated withstand voltage and insulation testing can significantly improve production efficiency and quality consistency. This not only reduces human error but also shortens product development cycles.

Market Opportunities

With the rapid growth of 5G communications, smart homes, electric vehicles, industrial automation, and medical devices, the demand for high-performance PCB transformers continues to rise. Companies that can provide reliable, compact, and efficient PCB transformers, particularly in key applications such as power management, signal isolation, and power conversion, will see significant market opportunities.

Sustainable Development and Environmental Protection Requirements

With growing global attention to environmental protection and energy conservation, the design and manufacture of PCB transformers will need to meet green manufacturing standards. The use of low-loss magnetic cores, environmentally friendly insulation materials, and designs that optimize energy efficiency will be key factors for companies to stand out in the international market.

In summary, PCB transformers are not only functional components in circuits but also a vital force driving electronic product innovation and industry upgrades. Companies and engineers must keep pace with technological developments, prioritize quality and efficiency, and meet market demands to achieve a leading position in the PCB transformer market.

Summary

As an indispensable core component in modern electronic devices, the PCB transformer’s value far exceeds simple voltage conversion. By gaining a deep understanding of their fundamental principles, types of applications, key design and manufacturing considerations, and performance testing methods, engineers and procurement personnel can make more informed decisions when selecting and optimizing circuits. With the advancement of miniaturization, high frequency, intelligent, and environmentally friendly requirements, PCB transformers face not only technical challenges but also unprecedented market opportunities. Whether in consumer electronics, industrial control, communications networks, medical equipment, or new energy, mastering the core knowledge of PCB transformers means achieving higher efficiency, greater reliability, and greater competitiveness in design, manufacturing, and selection. For this reason, PCB transformers are not only the functional core of electronic circuits but also a key driver of industry innovation and development.