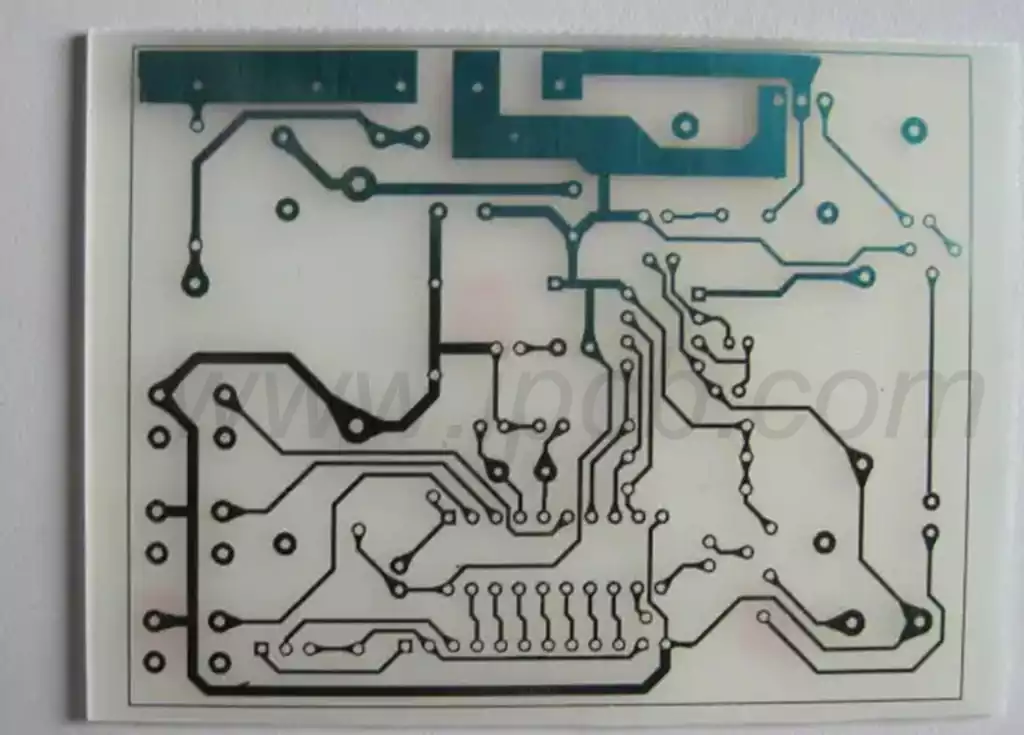

Semi flex pcb is essentially “standard” multilayer PCBs manufactured using specific grades of FR4. The thickness of the FR4 is subject to particular tolerances, enabling thinner sections to provide the flexible/bendable portions traditionally achieved with rigid FR4.

Semi flex pcb is suitable for static applications (where the flexible section aids assembly) or scenarios involving minimal bending. Typically, applications requiring only limited bending during installation, rework, or maintenance—rather than continuous dynamic flexing—present situations where conventional rigid-flex boards would be overkill and prohibitively expensive. In such cases, semi-flex boards represent the optimal choice.

Semi flex pcb is manufactured by incorporating controlled-depth milling or rigid-flex processing techniques (such as milling openings or windows) into standard rigid board fabrication. They are commonly produced using FR4 material. The PCB is first manufactured through standard processes, then milled thin at the required bending points to achieve flexibility. Typically employing an asymmetrical laminate structure, it satisfies the bending and connection requirements during assembly.

Semi rigid pcb represents a novel electronic component combining flexible substrates with semi-rigid circuitry. Their fabrication involves depositing a metallic film onto the flexible substrate, followed by photolithography and etching processes to form the semi-rigid circuit structure. The final assembly is achieved through bonding and cutting techniques. Semi rigid pcb, also termed semi-flex boards, are manufactured using specific grades of FR4 material and feature a ‘standard’ multilayer PCB structure. The FR4 thickness is controlled within defined parameters, enabling the thinner sections to exhibit flexibility or bend characteristics akin to conventional rigid FR4. These boards are primarily suited for static applications, such as assembly where the flexible portion is utilised, or scenarios involving minimal bending.

Flexible printed circuits broadly fall under the category of rigid-flex boards, with their bending conditions classified as: dynamic flex (multi-flex), static flex, and semi-flex; Dynamic flex: Bending radius 1mm, 180-degree flex, over one thousand cycles;

Static Flex: 1mm bending radius, 180-degree bend, over 100 cycles;

Semi-Flex: 5mm bending radius, 180-degree bend, over 10 cycles;

Flexible substrate selection must be determined by the operating environment.

Three manufacturing techniques are commonly employed for semi rigid pcb:

1.Pure FR4 rigid laminate with controlled depth milling to thin the material; by maintaining a specific thickness in the bending area, it functions as a flexible bend zone;

2.FR4 laminated with flexible layers, where PP film is precut with openings in areas requiring exposed flexibility, while rigid sections remain intact. The overhanging rigid areas are subsequently exposed via controlled-depth milling;

3.FR4 laminated with flexible material, employing open-window rigid-flex board technology on the FR4 and PP sheet at the required bend points prior to lamination. Each process has distinct advantages and disadvantages, differing in manufacturing costs and operational complexity. The optimal choice should be determined through testing based on the specific production equipment and capabilities of each manufacturer.

Potential Risks

Although semi-rigid board processing is simpler than conventional rigid-flex boards, the use of thinner materials makes them prone to damage. Due to immature processes and equipment, numerous production defects and risks persist:

1) When employing the first milling technique, stringent depth control precision is required. Thickness uniformity significantly impacts flexural performance; uneven thickness readily causes fractures.

2) The second process carries risks of lamination indentation and semi-rigid cracking. Indentations directly cause poor film adhesion and circuit defects, while adhesive overflow complicates cover removal;

3) The third method employs standard thin FR4 core or semi-rigid material for bending zones, introducing fracture and damage risks. Extra care is required during subsequent processing to protect these areas. Despite presenting more risks and challenges than rigid printed circuit boards, semi-rigid boards remain relatively easier to manufacture than rigid-flex boards. By applying the production model of rigid-flex boards, coupled with precise control of lamination and depth-controlled milling, high-quality semi-rigid boards can be produced.

Characteristics of semi flex pcb

By substituting polyimide-based FCCL with thin rigid FR4 laminates or semi-flexible CCL, this technology significantly reduces production costs.

Utilising thin rigid FR4 offers lower moisture absorption than flexible PI materials, eliminating the need for post-baking tempering prior to further processing.

It offers superior dimensional stability compared to flexible substrates.

Like R-FPC (multiflex), it enables three-dimensional mounting possibilities.

It reduces procurement and logistics costs associated with additional cables, connector assemblies, and solution design processes.

Enhanced reliability through fewer interfaces.

Semi-flex products are primarily employed in automotive electronics, heavy machinery, and data communications sectors. They meet contemporary substrate interconnection requirements for high system reliability, short installation times, low mounting costs, and three-dimensional mounting to the greatest extent. Building upon rigid PCB foundations, specialised processing techniques impart partial flexibility. Compared to traditional rigid-flex PCBs, semi flex PCB substantially reduce material costs, manufacturing expenses, and production complexity while accommodating limited localised bending requirements. Concurrently, they deliver more stable and complete electrical signal transmission, partially replacing rigid-flex PCBs in certain applications. Against the backdrop of rapid growth in the rigid-flex PCB market, this will substantially boost the adoption of semi flex PCBs.

As an innovative bridge between rigid and flexible PCBs, semi flex pcb occupys a significant position in modern electronics manufacturing due to their unique cost-effectiveness, structural advantages, and reliability.Despite certain technical challenges and potential risks in their production process, the quality and application scope of semi-rigid boards will continue to expand with the ongoing maturation of manufacturing techniques and advancements in precision control technologies. In cost-sensitive applications requiring only limited bending, semi rigid pcb undoubtedly represent an ideal solution for achieving high-performance, highly integrated electronic products, heralding broader development prospects within the future electronics industry.