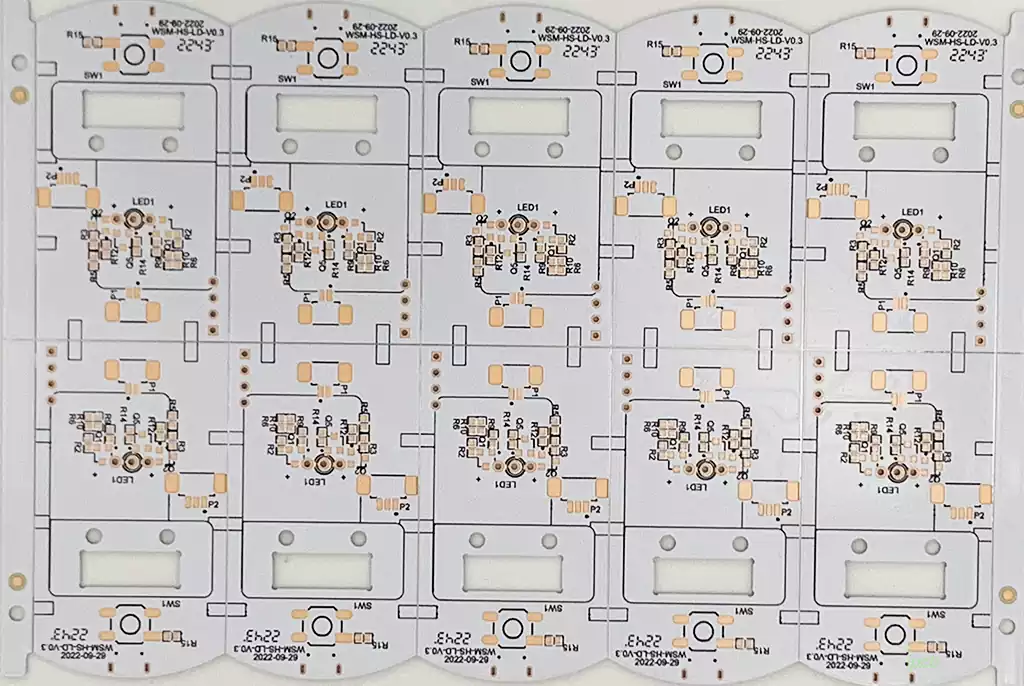

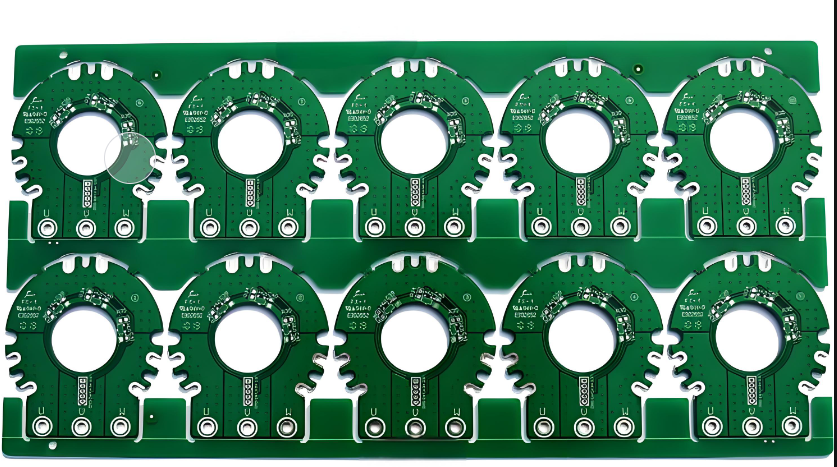

The CCL (Copper Clad Laminate) lamination process utilizes high-temperature and high-pressure conditions to achieve a tight and robust bond between the copper foil and substrate within the laminate. This process is centered on producing high-quality, high-performance PCBs (Printed Circuit Boards), ensuring the CCL meets the electrical, mechanical, and chemical properties required for PCBs.

CCL Laminating Process Flow

- Material Preparation:

Prepreg and copper foil preparation constitute the first step in the laminating process. Prepreg is a material formed by impregnating glass fiber cloth or wood pulp paper with epoxy resin and drying it to a semi-cured state, exhibiting certain viscosity and flowability. Copper foil serves as the metallic layer for forming conductive circuits. - Layer Assembly:

Before the laminator begins operation, prepregs and copper foil must be assembled in layers according to design specifications. Typically, a CCL consists of multiple prepreg layers sandwiched between upper and lower copper foil layers—a process analogous to making a “sandwich.” - Laminating Process:

The assembled material is fed into the laminator. Under specific pressure and temperature conditions (typically 175°C, 2-4 MPa), it undergoes approximately 60 minutes of compression and heating. This causes the resin within the prepreg to flow and fully cure, bonding all layers into a cohesive unit. - Cooling and Trimming:

After lamination, the board undergoes cooling to stabilize its structure. The cooled copper-clad laminate is then trimmed to remove excess edges and undergoes essential tests, including thickness, flatness, and insulation performance.

Core Technologies and Key Materials in CCL Laminating

Glass Cloth:

Serving as the substrate in copper-clad laminates, the quality of glass cloth directly and critically impacts the overall performance of CCL. High-quality glass cloth possesses numerous superior characteristics: high mechanical strength to withstand significant external forces without damage; low dielectric constant to minimize signal transmission loss; and excellent thermal stability to maintain performance in high-temperature environments.

Epoxy Resin:

As the primary resin material in copper-clad laminates, epoxy resin’s performance decisively influences the electrical and mechanical properties of the CCL. Resin selection must prioritize high-temperature stability to ensure structural integrity and performance consistency under elevated conditions. It must also exhibit excellent dielectric properties to guarantee efficient signal transmission. Additionally, suitable flowability is crucial for uniformly filling material voids during the lamination process.

Copper Foil:

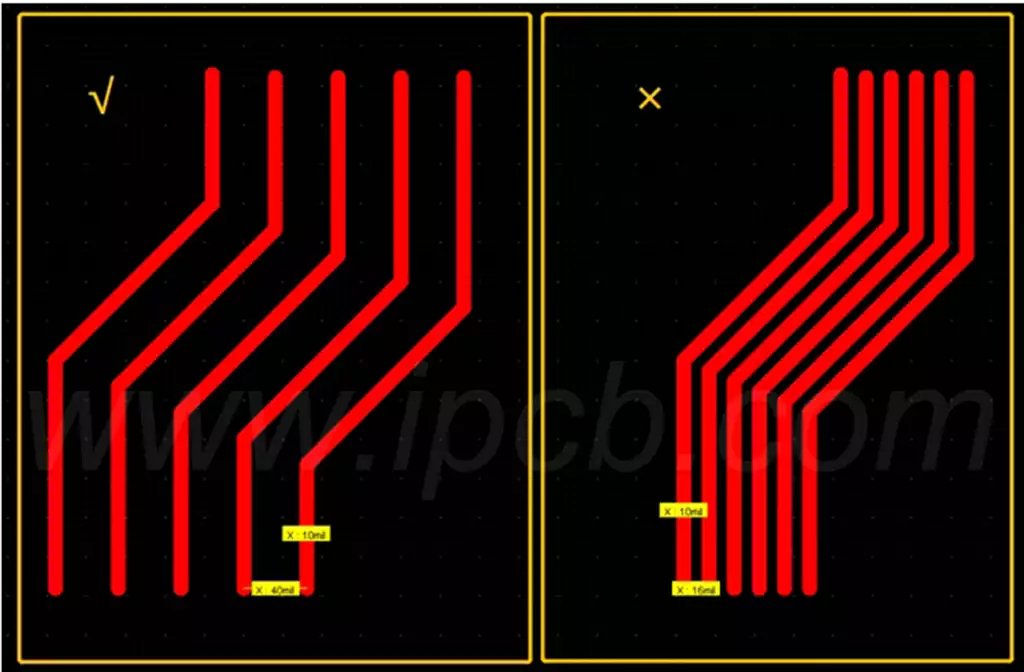

As the metallization layer, copper foil directly participates in circuit pattern formation within CCL. Surface treatment processes—such as electrolytic treatment and mechanical thickening—significantly impact the quality and reliability of pattern transfer. Different treatments impart distinct surface characteristics to the copper foil, thereby influencing its bonding effectiveness with the substrate and the precision of circuit patterns.

Laminator:

The laminator is the core equipment in the CCL lamination process. It precisely controls the two critical parameters of pressure and temperature, serving as a key factor in ensuring lamination quality. Modern high-performance laminators are powerful, featuring multi-zone temperature and pressure control capabilities that allow precise adjustments based on material properties and process requirements. They also possess rapid heating functions, effectively boosting production efficiency while ensuring process stability and consistency.

Application Fields of CCL Laminating

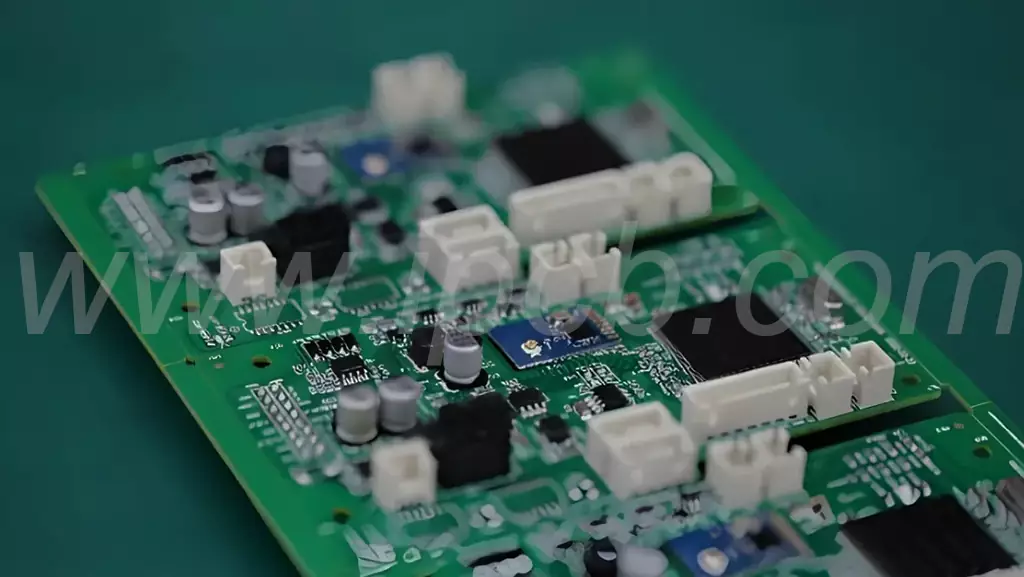

Communication Equipment: Communication devices demand extremely high signal transmission standards. Utilizing high-performance CCL effectively enhances signal integrity and anti-interference capabilities. Its importance is particularly prominent in 5G communication equipment.

Automotive Electronics: With the advancement of automotive intelligence, electronic components such as electronic control units (ECUs) and sensors are extensively applied in vehicles. High-reliability CCL ensures the stability and durability of these electronic components.

Medical Devices In medical equipment, the reliability and stability of PCBs directly impact patient safety. High-performance CCLs deliver superior electrical performance and mechanical strength, ensuring the stable operation of medical devices.

CCL lamination is an indispensable critical process in PCB manufacturing, directly impacting the performance and quality of the final product. By selecting appropriate materials and precisely controlling temperature, pressure, and time during the lamination process, the quality of CCL can be effectively enhanced to meet the demands of high-performance electronic products. As electronic technology continues to advance, CCL lamination processes will also evolve, providing a solid foundation for higher-performance, more stable electronic products.