In modern wireless communication systems, antennas serve as the “bridge” connecting electromagnetic waves with electronic devices, their performance directly determining signal transmission efficiency and stability. With technological evolution, ceramic antennas have gradually become core components in high-frequency communications and satellite navigation, leveraging dual advantages in materials science and process innovation. Meanwhile, traditional metal antennas continue to dominate the mass market due to their low cost and ease of fabrication.

Material Differences

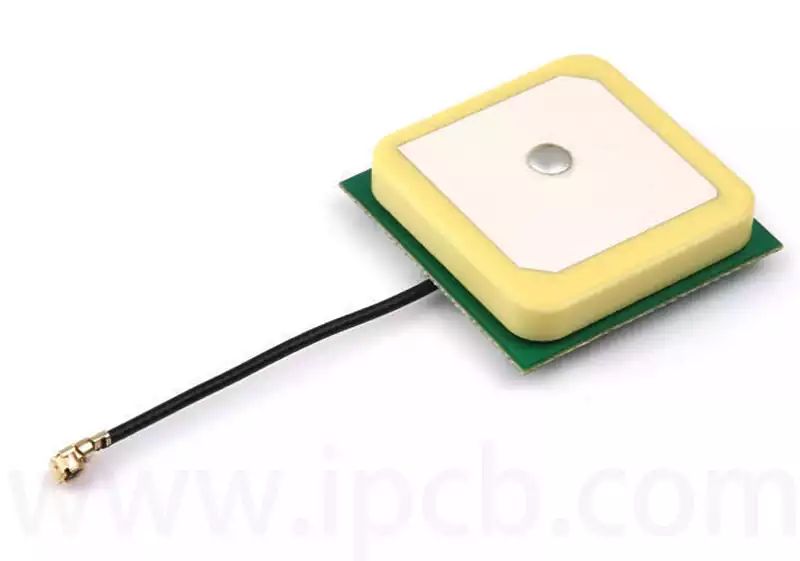

Ceramic antennas primarily utilise ceramic as their main material, characterised by high purity, excellent thermal stability, and superior mechanical properties. Conventional antennas, however, commonly employ metallic materials such as copper, aluminium, or tungsten.

Production Process Differences

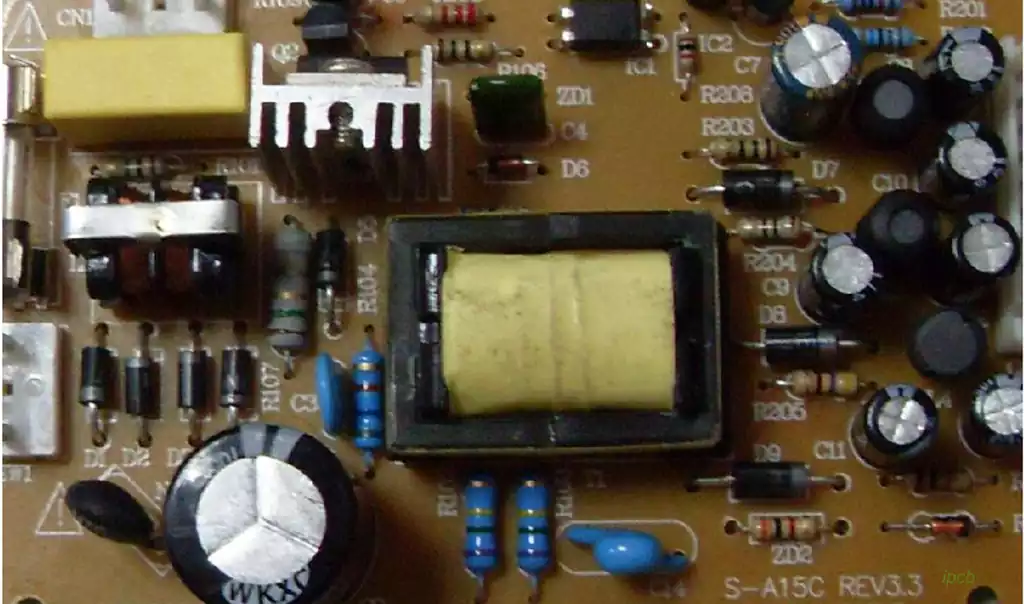

Ceramic antenna production involves relatively complex processes requiring advanced techniques like injection moulding and high-temperature sintering. In contrast, conventional antennas employ simpler manufacturing methods, primarily metal fabrication and welding.

Performance Variations

Ceramic antennas demonstrate superior interference resistance and corrosion tolerance, alongside low-temperature electrical properties, favourable thermal expansion coefficients, and exceptional stability. Additionally, they exhibit high sensitivity and signal-to-noise ratios, making them particularly suitable for high-frequency applications. Conventional antennas, however, are primarily employed for radiating and receiving lower frequency ranges. Their simple structure and low manufacturing costs lead to widespread adoption in civilian sectors.

Differing Application Domains

Typical applications of ceramic antennas:Their advantages are pronounced in scenarios demanding stringent performance criteria. In vehicle navigation systems, ceramic antennas ensure accurate positioning by receiving satellite signals with high gain, stability, and interference resistance. Within industrial automation equipment operating in complex electromagnetic environments, they maintain stable signal transmission and reception, guaranteeing reliable communication. For smart wearables demanding compact size and high performance, ceramic antennas fulfil these requirements through miniaturisation and stability, enabling seamless connectivity with smartphones.

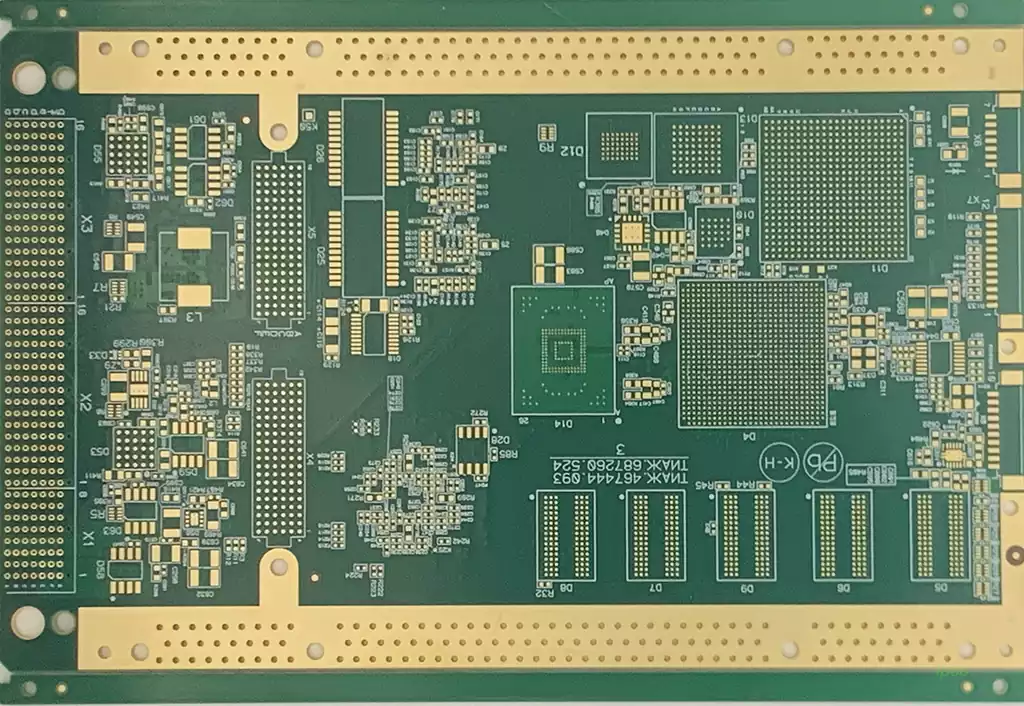

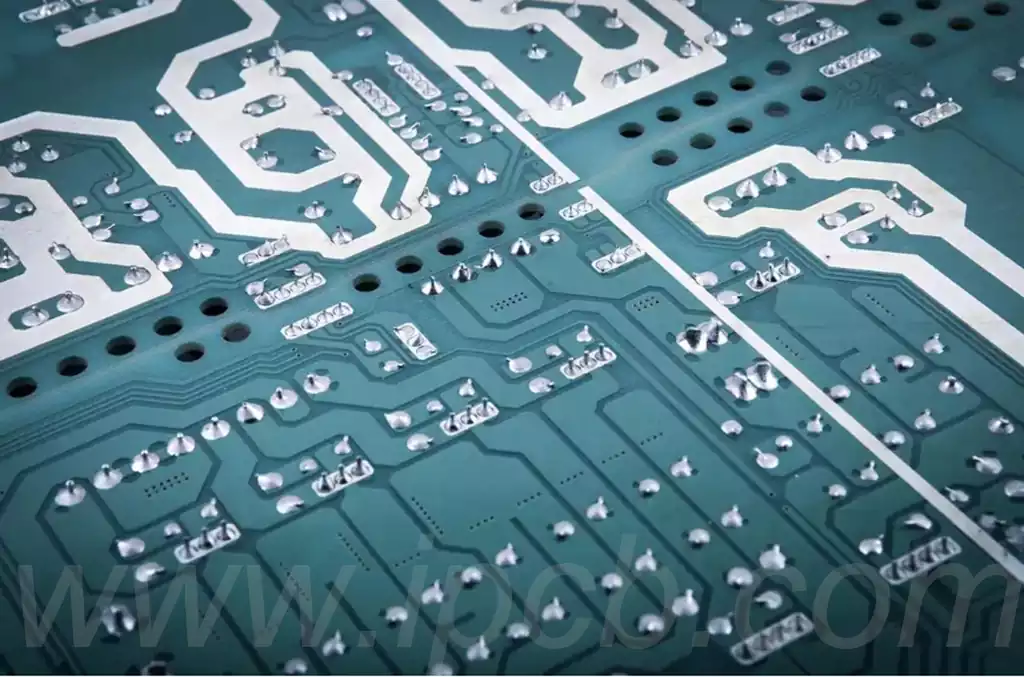

Common applications of conventional antennas: Conventional antennas are widely employed in scenarios with moderate cost and performance requirements. Devices in smart homes, such as door/window magnetic sensors and temperature/humidity sensors, demand little in terms of signal strength and stability. PCB antennas, with their low cost and ease of integration, are favoured for consumer electronics like radio receivers and simple wireless doorbells. Basic signal reception needs can be met using metal rod antennas, eliminating the need for high-cost, high-performance alternatives.

Cost Differences

Ceramic antennas incur relatively higher costs due to specialised materials and complex manufacturing processes. Their ceramic substrate materials are expensive, and production steps like high-temperature sintering and precision metallisation increase manufacturing expenses, typically resulting in unit prices of several yuan or more. Standard antennas, utilising common materials and straightforward processes, offer significant cost advantages. Metal antennas benefit from low raw material costs and mature processing techniques, enabling unit costs as low as a few pence during mass production. PCB antennas, integrated with PCB board manufacturing without additional complex processes, also achieve effective cost control, making them suitable for cost-sensitive products.

The dielectric constant of ceramic antennas

The dielectric constant of ceramic antennas typically ranges between 2 and 10, though specific values are influenced by multiple factors. Firstly, material composition and structure affect the dielectric constant, with different ceramic compositions exhibiting distinct dielectric properties. Secondly, temperature and frequency also impact the dielectric constant. Under specific conditions—such as particular ceramic compositions and structures at particular temperatures and frequencies—the dielectric constant may even reach 100 or higher.

To ensure accuracy, professional measurement methods such as the resonance method, short-circuit method, or reflection method are required to determine the dielectric constant of ceramic antennas in practical applications. These techniques provide reliable dielectric constant values, serving as a basis for antenna design and performance optimisation.

Dielectric Constant of Satellite Ceramic Antennas

Satellite communications demand exceptionally high antenna performance, leading to widespread adoption of ceramic antennas in this field. Satellite ceramic antennas typically exhibit a high dielectric constant to accommodate high-frequency and demanding operational environments. Specifically, their dielectric constant may exceed 10 and reach even higher values under specific conditions. Such high-dielectric-constant ceramic antennas deliver superior signal transmission performance and enhanced interference resistance, meeting the stringent requirements of satellite communications.

Ceramic antennas and conventional antennas exhibit distinctly different characteristics across multiple dimensions. Ceramic antennas hold a significant position in high-frequency communications due to their outstanding interference resistance, corrosion resistance, and high sensitivity. In contrast, conventional antennas are widely used in civilian applications owing to their low cost and ease of manufacture.

The dielectric constant of ceramic antennas, as a core performance parameter, not only influences antenna design but also directly impacts communication quality. Looking ahead, with continuous technological advancements, ceramic antennas are poised to play a pivotal role in more fields, driving the ongoing development of wireless communication technologies.