The Core Role of the Refrigerator PCB Board in Modern Refrigerators

In modern home appliance systems, refrigerators are no longer simply refrigeration devices, but complex electronic systems integrating multiple functions such as temperature control, drive, communication, energy management, and intelligent interaction. Behind these functions, the refrigerator PCB board truly plays the role of “central control.” It is not merely a simple circuit carrier, but the core assembly of the refrigerator’s overall logic, execution, and safety mechanisms, directly determining the product’s performance limits, stability, and lifespan.

From a system architecture perspective, a refrigerator typically contains multiple subsystems, such as the compressor drive system, fan and defrosting system, temperature and humidity sensing system, display and human-machine interface module, and the increasingly prevalent intelligent networking module. These subsystems do not operate independently but work collaboratively through main and sub-control PCBs. The refrigerator PCB board’s task is to unify these dispersed functions onto a stable, controllable, and mass-producible electronic platform, enabling the entire unit to operate continuously for many years under different operating conditions without logical instability or failure.

At the refrigeration control level, the PCB board not only receives real-time data from temperature sensors but also needs to finely schedule the compressor’s start-stop frequency, runtime, and temperature control strategies for different refrigeration zones. Especially in inverter and multi-zone refrigerators, the control logic is more complex, placing higher demands on the PCB’s stability and anti-interference capabilities. An immature control board may function normally in the short term, but under long-term operation or power grid fluctuations, it will expose problems such as program malfunctions, false triggers, or control delays, ultimately affecting the overall reliability of the refrigerator.

From a safety perspective, the refrigerator PCB board also plays a crucial protective role. Refrigerators are household appliances that operate 24/7, constantly powered, making protection against overcurrent, overvoltage, surges, electromagnetic interference, and abnormal operating conditions paramount. The power management circuitry, protection component layout, and grounding design on the PCB directly affect the refrigerator’s safety performance in extreme environments. This is why high-end refrigerator brands often conduct extensive reliability testing and aging verification during the PCB design phase, rather than simply copying generic solutions.

Furthermore, with the development of smart homes, refrigerators are gradually becoming an important node in the home Internet of Things (IoT). The introduction of Wi-Fi, Bluetooth, and even cloud communication capabilities necessitates that refrigerator PCB boards simultaneously accommodate analog signals, power circuits, and high-speed digital communication. This multi-signal hybrid design places more systematic demands on the PCB’s layer stack-up structure, impedance control, electromagnetic compatibility, and long-term stability, transforming refrigerator control boards from “low-end appliance PCBs” into high-reliability electronic products.

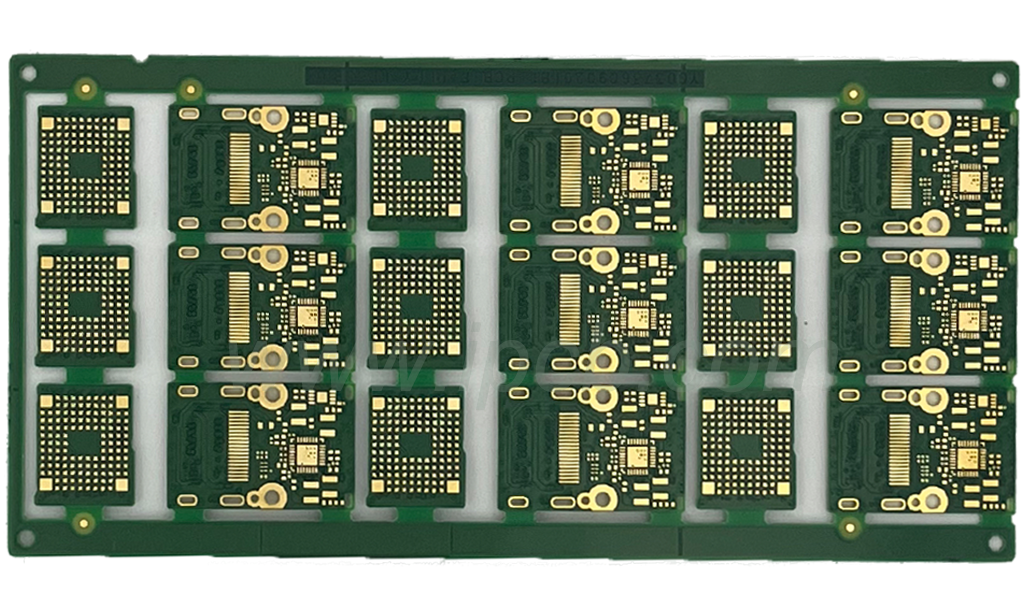

From a manufacturing and supply chain perspective, refrigerator PCBs must also possess excellent mass production capabilities and consistency. Refrigerators are high-volume, long-lifecycle products, and a single PCB design often requires stable supply for many years. Therefore, material selection, component layout, soldering process windows, and post-design maintainability are all factors that must be comprehensively considered during the design phase. This also determines that the value of a refrigerator PCB board lies not only in its technical aspects but also in its long-term impact on overall product cost, yield, and after-sales risks.

In conclusion, the refrigerator PCB board is not an insignificant component inside the refrigerator, but a crucial foundation supporting the overall functionality, safety, and intelligent evolution of the machine. Understanding its core position in the system is a prerequisite for further discussion of its structural design, material selection, reliability requirements, and future development trends.

Refrigerator PCB Board Structural Design and Functional Module Analysis

In actual refrigerator electronic systems, the refrigerator PCB board is not a single-function control board, but rather a highly customized electronic system carrier that is broken down, combined, and customized around the overall operating logic of the refrigerator. Refrigerators of different brands, positioning, and functional levels exhibit significant differences in their PCB architecture, but they all follow a highly consistent engineering logic in their core design approach: using modular design to stably operate complex functions in long-term, high-load usage environments.

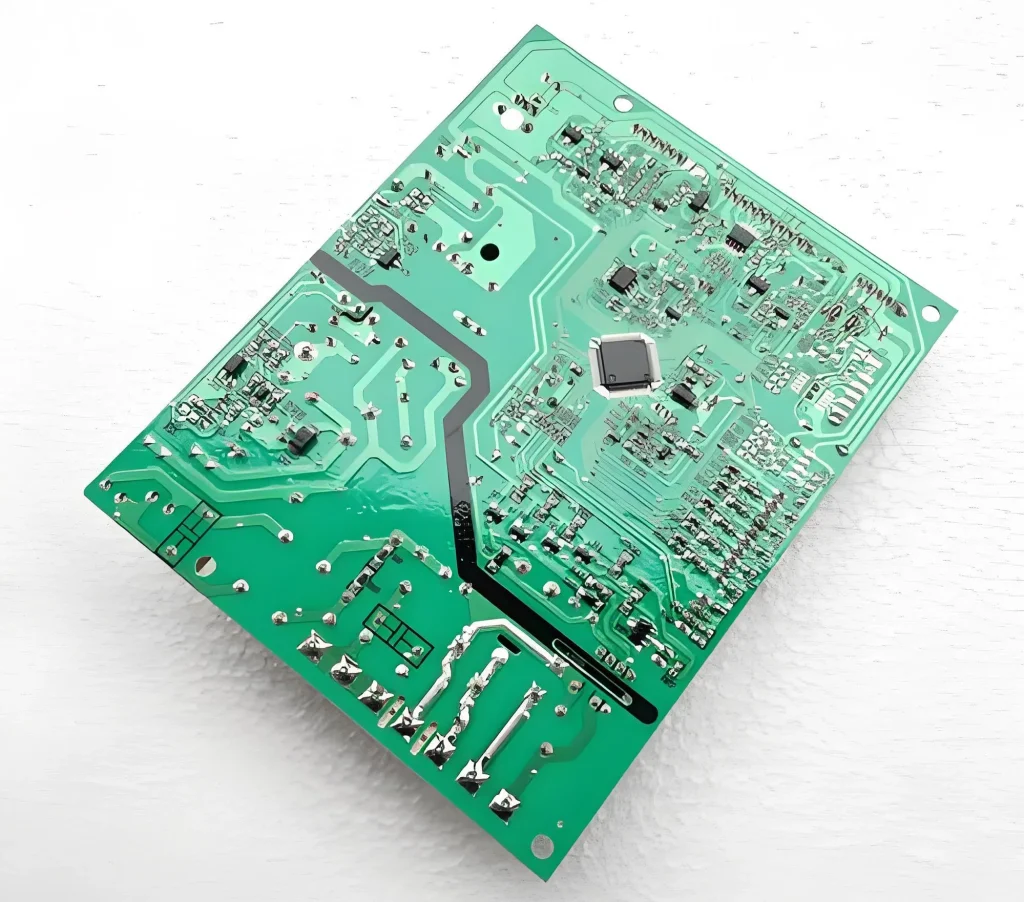

From an overall structural perspective, a refrigerator typically includes at least a main control board and several functional sub-boards. The main control board plays the role of overall logic scheduling, handling data input from temperature sensors, door switches, display panels, and communication modules, and outputting control commands according to predetermined algorithms. The fan board, display board, and driver board, among other sub-boards, are responsible for executing specific actions. This master-slave PCB architecture effectively reduces single-board complexity, improves system stability, and facilitates later maintenance and upgrades.

The design of the refrigerator PCB board is particularly critical in the power supply and power management module. The refrigerator contains both low-voltage digital circuits and circuits driving power loads such as the compressor, fan, and defrost unit. This requires the PCB to achieve safe isolation between high-voltage and low-voltage areas within the same system, and to have good creepage distances and insulation design. The power module must not only be highly efficient but also maintain stable output under conditions of grid fluctuations and voltage surges; otherwise, it will directly affect the reliability of the control system and may even lead to abnormal shutdown of the entire unit.

The control and processing module is the “central nervous system” of the refrigerator PCB. Its core is usually an MCU or dedicated control chip, used to handle temperature control logic, operating status judgment, and anomaly handling. In inverter refrigerators and multi-temperature zone systems, the control algorithm is more complex, and the selection of chips on the PCB, crystal oscillator stability, and peripheral circuit layout all directly affect the system’s response speed and operational stability. Any noise, jitter, or false triggers caused by improper design can be amplified over long-term operation, ultimately affecting the user experience.

The sensing and feedback module is also a crucial and indispensable component of the refrigerator PCB board. Multiple temperature sensors are located inside the refrigerator, sometimes including humidity, frost, or load detection devices. These signals are typically weak analog signals, highly sensitive to external interference. Therefore, in the PCB layout, sensor signal traces need to be kept away from power devices, and proper grounding and filtering designs should be employed to ensure the accuracy and reliability of the collected data. Accurate data input is fundamental to achieving precise temperature control and energy-saving operation.

The human-machine interface and display module is the part most directly perceived by the user. The display board is typically connected to the main control PCB via ribbon cables or connectors, responsible for displaying temperature status, operating mode, and alarm information. With the development of smart refrigerators, touch screens, color displays, and even voice interaction have been introduced, placing higher demands on the PCB’s signal integrity, electromagnetic compatibility, and interface reliability. This makes the communication design between the display and control systems a key consideration in the PCB architecture.

In recent years, the proportion of communication and smart modules in refrigerator PCB boards has been steadily increasing. The addition of Wi-Fi, Bluetooth, or cloud communication modules enables refrigerators to achieve remote control, status monitoring, and software upgrades. However, these high-speed digital signals are extremely sensitive to PCB design, requiring careful planning of antenna placement, RF traces, and shielding structures to avoid interference with the existing control system. This is also a major technical challenge faced by many traditional home appliance PCBs when upgrading to smart technology.

From an engineering perspective, the structural design of a refrigerator PCB is essentially a systems engineering project prioritizing long-term stability. Compared to the pursuit of thinness and extreme performance in consumer electronics, refrigerator PCBs emphasize durability, environmental adaptability, and fault tolerance. The existence of each module is the result of a trade-off between long-term operation, complex operating conditions, and mass production.

Materials Selection, Manufacturing Processes, and Reliability Challenges of Refrigerator PCB Boards

Unlike short-lifecycle consumer electronics, refrigerators are typical long-cycle operating devices, often requiring stable operation for over ten years under continuous power supply or high-frequency start-stop conditions. This usage characteristic dictates that the selection of materials and manufacturing processes for refrigerator PCB boards must prioritize reliability, rather than simply pursuing cost or size reduction. Any material or process issues overlooked in the early stages can translate into high after-sales risks during long-term operation.

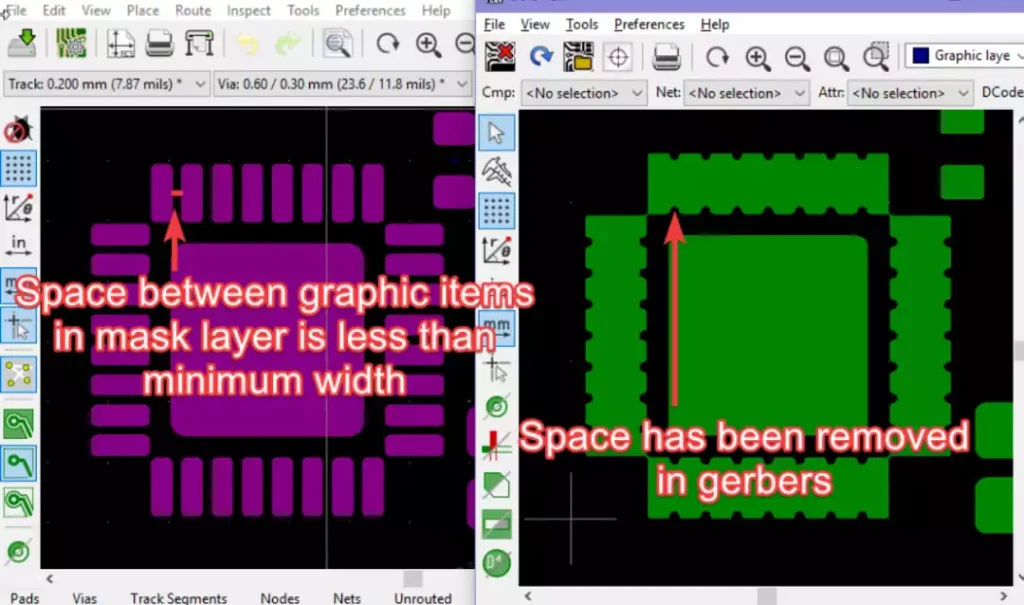

Regarding substrate selection, refrigerator PCBs typically use FR-4, but not all FR-4 is suitable for the refrigerator’s control environment. The interior of a refrigerator is constantly exposed to low temperatures, high humidity, and even condensation. Ordinary low-Tg materials are prone to dielectric drift, board warping, or decreased interlayer bonding under temperature cycling and humidity stress. Therefore, in practical applications, it is preferable to choose material systems with medium to high Tg, low moisture absorption, and stable lamination structures to ensure the PCB maintains dimensional and electrical stability during repeated temperature changes.

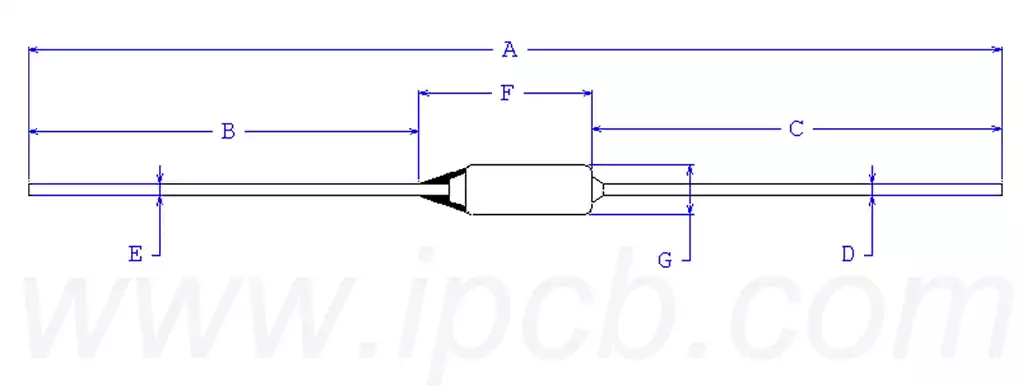

The design of the copper foil and circuit structure also directly affects reliability. Refrigerator PCBs often contain both low-current signal lines and power traces driving the compressor, heater, and fan. This requires the traces to have sufficient current carrying capacity while controlling temperature rise and electromagnetic interference. If the copper thickness is not chosen appropriately or the trace width is insufficient, localized overheating, solder joint fatigue, or even circuit aging and breakage may occur during long-term operation. Therefore, in the design of refrigerator PCB boards, thicker copper foil or wider traces are often used in the power supply area to improve overall durability.

At the manufacturing process level, soldering quality is one of the key factors affecting the lifespan of a refrigerator PCB. During long-term operation, refrigerators experience repeated thermal expansion and contraction, and solder joints bear continuous mechanical stress. If the soldering process window is not properly controlled, it is easy to produce cold solder joints, voids, or stress concentrations. These problems may not be immediately apparent during factory testing but will gradually emerge after several years of use. Therefore, high-reliability refrigerator PCB boards typically consider pad shape, component package matching, and solder selection during the process design stage to improve the fatigue resistance of solder joints.

Environmental adaptability is also a significant challenge for refrigerator PCBs. The humidity inside a refrigerator changes frequently, especially during defrosting and high-humidity environments. Moisture may condense on the PCB surface or near component leads, leading to corrosion or leakage risks. To address this issue, some high-end refrigerator control boards employ protective coatings or special surface treatments to enhance resistance to humidity, heat, and contamination. While these measures increase manufacturing costs, they offer significant value in extending product lifespan and reducing after-sales failure rates.

Furthermore, electromagnetic compatibility (EMC) is equally crucial in refrigerator PCB boards. The starting and stopping of the compressor and fan generate strong electromagnetic interference. If filtering, grounding, and isolation strategies are not adequately considered during the PCB design and manufacturing phases, it can lead to control system malfunctions or communication anomalies. These problems are often sporadic and subtle, making troubleshooting difficult once they occur. Therefore, in a reliability-oriented design approach, EMC is not a post-hoc remedy but a core element that must be integrated into material selection and process implementation.

In summary, the reliability of a refrigerator PCB is not determined by a single factor but is the result of the combined effects of material properties, manufacturing processes, and environmental adaptability. The true value of a refrigerator PCB board lies in its ability to continuously and stably support the operation of the entire unit under complex, long-term, and unpredictable usage conditions. This is the most fundamental difference in design philosophy between home appliance electronics and general consumer electronics PCBs.

Common Failure Modes and Key Quality Control Points for Refrigerator PCB Boards

In refrigerator system failure analysis, the electronic control system is always a key focus, and a significant portion of problems ultimately trace back to the design, manufacturing, or environmental adaptation of the refrigerator PCB board. Unlike disposable or short-cycle electronic products, refrigerator PCB failures often exhibit slow accumulation, insidious occurrence, and difficulty in reproduction, making early quality control and design decisions particularly crucial.

One of the most common failure modes is solder joint fatigue caused by temperature cycling. During long-term operation, the refrigerator compressor frequently starts and stops, and the environment around the control board constantly experiences temperature changes. Different materials have different coefficients of thermal expansion; when solder joints are subjected to prolonged mechanical stress, microcracks gradually form and propagate, eventually leading to intermittent contact failures. These problems are often difficult to detect in early testing but manifest as random crashes, false alarms, or functional malfunctions after several years of use, posing significant challenges for after-sales troubleshooting.

Moisture-related failures are another major challenge facing refrigerator PCB boards. The interior of a refrigerator is not a constantly dry environment. During defrosting, door opening and closing, or use in high-humidity areas, moisture may condense on the PCB surface. If the board has a high moisture absorption rate or insufficient surface protection, long-term exposure can easily lead to metal corrosion, decreased insulation resistance, and even electrochemical migration. These failures are often slow-progressing but irreversible; once they occur, they are difficult to repair and require replacement of the entire board.

The aging issues in the power supply and power areas are equally significant. Loads such as compressors, heaters, and fans generate large current surges during startup. If the PCB design does not adequately consider power traces, copper thickness, or heat dissipation paths, localized temperature rises will accelerate material aging. In the long term, this can lead to decreased power module performance, component parameter drift, or even breakdown failure. These problems not only affect the refrigerator’s operational stability but may also pose safety hazards.

At the control logic level, some anomalies that appear to be “software problems” actually originate from PCB design or manufacturing quality. For example, poor grounding or signal interference may cause the control chip to misinterpret sensor data, triggering abnormal operating modes. These types of failures often manifest as sporadic errors, making them extremely difficult to fully reproduce in a laboratory. Therefore, during the quality control phase, it is crucial to reduce their probability of occurrence through sound layout design and manufacturing consistency.

To address these potential risks, quality control should focus on the entire lifecycle of the refrigerator PCB board. During the design phase, thorough reliability analysis and redundant design should be implemented to proactively avoid high-risk structures. During the manufacturing phase, rigorous material control, process verification, and process monitoring should be employed to ensure consistent performance across each batch. Before shipment, functional testing, aging testing, and environmental stress screening should be combined to identify potential problems as early as possible.

It’s important to note that the quality of a refrigerator PCB isn’t just about whether it “works normally,” but also about whether it maintains consistent performance after years of operation. Many cost differences actually stem from the level of investment in long-term reliability. For manufacturers pursuing brand value and user reputation, choosing a reliable PCB design and manufacturing solution is essentially buying insurance against future after-sales risks.

Refrigerator PCB Board Development Trends and Design Concepts

As the home appliance industry continues to evolve towards high-end, intelligent, and low-energy consumption, the design philosophy of refrigerator PCB boards is also undergoing significant changes. In the past, refrigerator control boards focused more on implementing basic functions; now, their role is shifting towards “a long-term stable intelligent control platform.” This shift places higher demands on PCB design concepts, manufacturing standards, and overall system coordination capabilities.

Firstly, system integration is constantly increasing. To reduce wiring complexity and improve overall reliability, more and more functions are being concentrated on a few core PCBs. This requires more rational partitioning and planning of power, control, communication, and power modules during the design phase to avoid thermal management and electromagnetic interference problems caused by high integration. Refrigerator PCB boards are no longer merely the result of circuit assembly, but rather a manifestation of system-level architecture design.

Secondly, reliability design is being moved upstream. As market competition intensifies, manufacturers are increasingly aware of the importance of after-sales costs and brand reputation, thus incorporating environmental stress, lifespan prediction, and failure mode analysis into the early stages of PCB design. This “proactive reliability” approach leads to more cautious material selection, soldering processes, and structural design, significantly improving the stability of the control board during long-term operation.

Simultaneously, the trend towards intelligentization presents new challenges to PCB design. The introduction of communication modules, remote upgrades, and data acquisition functions requires refrigerator PCB boards to handle high-speed digital and radio frequency signals in traditional home appliance environments. This not only tests design capabilities but also places higher demands on manufacturing consistency; otherwise, even with a reasonable design, performance fluctuations may occur during mass production.

Finally, from a supply chain perspective, refrigerator PCB design increasingly emphasizes sustainable supply and maintainability. Stable material systems, mature process routes, and compatibility with alternative components are becoming important criteria for evaluating whether a control board is “suitable for mass production.”

Summary

the refrigerator PCB board is the core component in a refrigerator’s electronic system that truly determines its long-term reliability. It not only carries the control logic and functional implementation but also subtly influences the overall safety, stability, and lifespan of the refrigerator. From structural design to material selection, from manufacturing processes to failure control, every detail lays the groundwork for the refrigerator’s performance years to come. As refrigerator products continue to upgrade towards intelligence, high performance, and low energy consumption, the PCB is no longer a passive accessory but a crucial support for the overall quality and brand value of the appliance. Understanding and valuing the engineering logic of the refrigerator PCB is fundamental to building highly reliable home appliances.