The Fundamental Role of SMT Connectors in Modern Electronic Systems

In modern electronic products, connectivity is no longer just a matter of “conduction,” but a critical factor directly related to system stability, signal integrity, and long-term reliability. SMT connectors have become a mainstream choice in this context. Compared to traditional through-hole connectors, it’s not simply a change in packaging form, but a systemic upgrade driven by the trends of miniaturization, high density, and automated manufacturing in electronic products.

From a system perspective, the core value of SMT connectors lies in their direct integration into surface mount technology (SMT) processes, ensuring high compatibility with mainstream SMT production workflows. This compatibility not only improves production efficiency but, more importantly, reduces the uncertainties introduced by manual assembly. In large-scale mass production environments, the soldering consistency, positional accuracy, and mechanical stability of connectors have a cascading impact on the overall quality of the device, and SMT methods possess natural advantages in these areas.

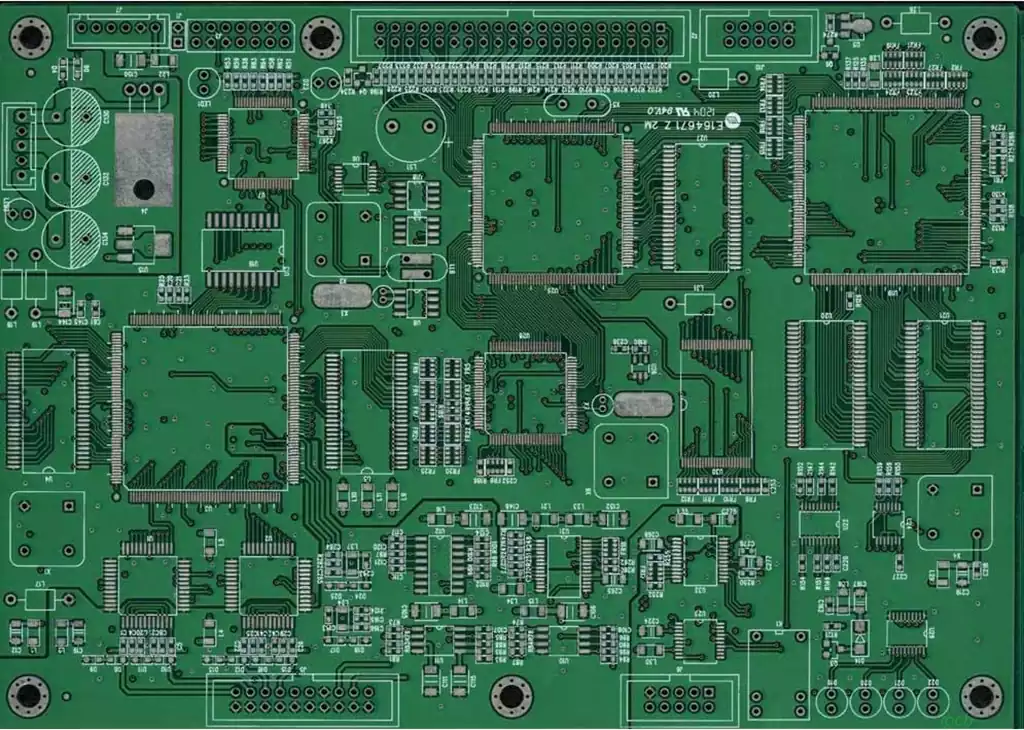

In today’s increasingly compact electronic system architectures, PCB space has become an extremely valuable resource. SMT connectors typically offer lower mounting heights and more flexible layouts, allowing designers to connect more functional modules within limited board space. This is particularly evident in consumer electronics, industrial control, and communication equipment. Connectors are no longer just “interfaces” but integral parts of the PCB design; their size, orientation, and pad type all influence the overall circuit layout and signal path planning.

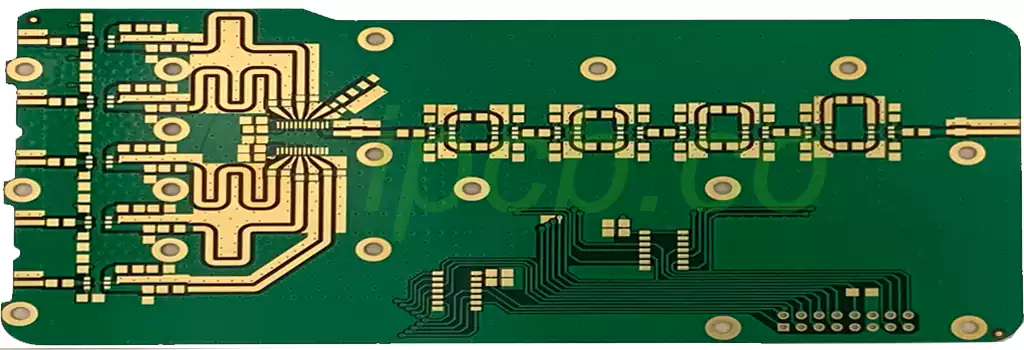

From an electrical performance perspective, the pin structure and soldering method of SMT connectors provide more controllable parasitic parameters in high-frequency and high-speed applications. As signal rates continue to increase, impedance discontinuities, reflections, and crosstalk issues introduced by connectors become increasingly prominent. Properly designed SMT connectors can improve signal integrity at the system level by shortening signal paths, optimizing grounding structures, and reducing unnecessary vias. This is why SMT connection solutions are preferred in high-speed communication modules and high-density control boards.

Reliability is another crucial reason for the widespread acceptance of SMT connectors. In long-term operation or complex environments, connectors are often among the first components to exhibit problems. Surface mount structures, by firmly fixing connectors to the PCB with solder joints, offer greater stability in terms of vibration and shock resistance. This stability is particularly critical for industrial equipment, home appliance control systems, and automotive electronics, as any momentary contact failure can trigger system malfunctions.

From a manufacturing and cost perspective, SMT connectors are also better suited to the large-scale demands of modern electronics manufacturing. They can be soldered simultaneously with other surface-mount components, reducing additional steps and improving production line utilization. While they may not be the lowest cost per unit, SMT connection solutions often offer superior overall cost-effectiveness in terms of manufacturing efficiency, yield, and subsequent maintenance risks.

In general, SMT connectors are not merely an evolution of connector form factors, but rather a product of the continuous upgrading of modern electronic systems in terms of design concepts, manufacturing methods, and reliability requirements. Understanding their fundamental role in systems is a prerequisite for in-depth discussions of their structural forms, application scenarios, and selection logic.

Structural Design Logic and Engineering Implementation of SMT Connectors

In actual electronic products, the performance of SMT connectors does not depend solely on materials or brands; a deeper determining factor is whether their structural design matches the application scenario, PCB process, and system requirements. Surface mount technology (SMT) is not simply about “attaching” connectors to a board; it’s a comprehensive engineering design encompassing soldering reliability, mechanical stability, and electrical performance.

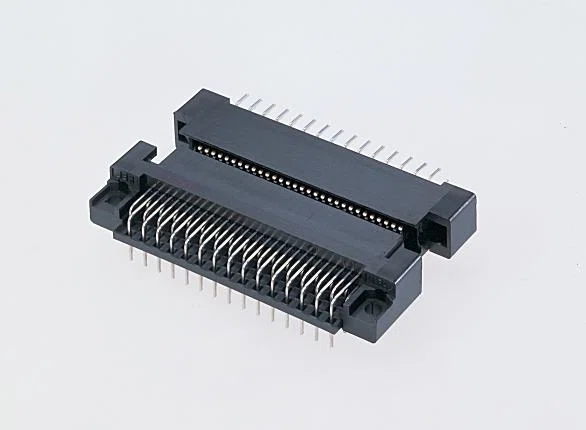

From a structural perspective, the core challenge of SMT connectors lies in achieving reliable connections without relying on through-hole support. Unlike through-hole connectors that mechanically fix themselves to the PCB through pins, SMT connectors primarily rely on pads and solder joints for fixation and conductivity. This requires their bottom structure to distribute insertion/extraction forces, vibrations, and external forces effectively across multiple solder joints, rather than concentrating them in a single location. Therefore, many SMT connectors incorporate additional metal retaining feet or positioning pads beyond the signal terminals to enhance overall mechanical strength.

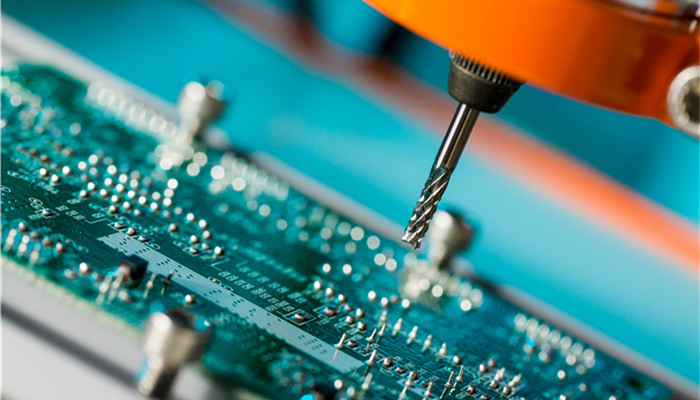

Pad design is a crucial factor in the long-term stable operation of SMT connectors. Connector pads are typically large and uniquely shaped; improper matching with PCB pads can easily lead to misalignment, tombstoning, or uneven solder distribution during reflow soldering. In engineering, pad scaling, solder mask window control, and stencil thickness adjustments are often used to achieve stable solder joint morphology. This is why connectors in SMT processes often require separate evaluation and cannot simply adopt the process parameters of ordinary surface-mount components.

From a terminal structure perspective, different SMT connectors exhibit significant differences in electrical and mechanical performance. Spring-loaded terminals emphasize contact stability and repeated mating life, suitable for module connections requiring maintenance or replacement; rigid terminals prioritize structural strength and dimensional consistency, often used for internal fixed connections. If the transition area between the terminal and solder joint is poorly designed, stress concentration can easily occur under temperature cycling or vibration, becoming a potential failure point.

In high-density applications, the spacing design of SMT connectors is particularly critical. As pin pitch continues to shrink, solder bridging, cleaning residue, and electrical creepage distance issues are amplified. This not only tests the manufacturing precision of the connector itself but also places higher demands on PCB fabrication capabilities. Therefore, in high-density designs, connector selection often needs to be evaluated in conjunction with the PCB manufacturer’s process capabilities, rather than being an isolated decision.

Furthermore, the fit between the connector housing and the PCB directly affects reliability. Proper height control reduces the leverage effect on solder joints during insertion and removal, while appropriate positioning structures help maintain connector stability during assembly and use. These seemingly “structural details” often determine whether SMT connectors will experience solder joint fatigue or contact abnormalities during long-term use.

From an engineering perspective, SMT connector design is essentially an art of balance, requiring reasonable trade-offs between size, strength, electrical performance, and manufacturability. Excellent design doesn’t pursue the ultimate in any single metric, but rather maintains long-term stable performance in real-world application environments.

Performance Priorities of SMT Connectors in Different Application Scenarios

While SMT connectors are highly versatile in structure, their design priorities and performance requirements vary significantly across different application scenarios. A truly mature selection is not about “whether it works,” but whether it can operate stably for a long time under specific environmental and usage conditions. This is why SMT connectors can exhibit vastly different performance characteristics in different products.

In industrial control and automation equipment, SMT connectors primarily face complex mechanical and environmental stresses. Equipment typically operates for extended periods, subjected to vibration, shock, and temperature variations, placing continuous stress on connector solder joints and contact interfaces. In these scenarios, the mechanical fixation capability and solder joint fatigue resistance of the connector are often more important than size or appearance. Designs typically select SMT connectors with additional fixing leads or metal reinforcement to distribute the mechanical load from insertion/removal and vibration, preventing solder joints from becoming weak points in the system.

In communication and high-speed data transmission equipment, performance concerns shift significantly to electrical characteristics. High-speed signals are extremely sensitive to impedance continuity, return loss, and crosstalk, and connectors are an indispensable segment of the signal chain. SMT connectors in these applications require precise terminal spacing control, stable grounding structures, and predictable parasitic parameters. If the connector design is mismatched with the PCB impedance control, it can lead to performance degradation of the entire system under high-frequency conditions, making it difficult to achieve the desired results even if other circuit designs are perfectly adequate.

In home appliances and consumer electronics, the role of SMT connectors is more about long-term reliability and manufacturing consistency. These types of products typically prioritize high throughput, low rework rates, and a stable user experience. Therefore, connectors need to maintain high consistency during automated placement and reflow soldering processes. Simultaneously, the temperature and humidity variations in the home appliance environment require connectors to possess excellent corrosion and aging resistance. For these applications, connectors with overly complex designs or excessive sensitivity to processes may actually become potential risks.

With the increasing prevalence of modular designs, SMT connectors also serve as interfaces for system expansion and maintenance. For example, in replaceable functional modules or upgradeable control units, connectors need to support a certain number of repeated mating and unmating cycles while maintaining stable contact. This requires a balance between abrasion resistance and conductivity in terminal materials and surface treatments to prevent performance degradation due to frequent operation.

Furthermore, different application scenarios have varying sensitivities to cost structures. In high-end equipment, connector stability and performance often take precedence over unit price, while in mass-production products, overall manufacturing costs and long-term yield are the core considerations. This means that the selection of SMT connectors cannot be decided in isolation from the overall system and business objectives.

Overall, the value of SMT connectors lies not in their “universality,” but in their “suitability.” Only by selecting connectors with a thorough understanding of the application environment, electrical requirements, and manufacturing conditions can their connectivity advantages in a system be truly realized.

Common Failure Modes and Key Reliability Control Points for SMT Connectors

In the actual operation of electronic systems, connectors are often not the most complex components, yet they frequently become the first point where problems surface. For SMT connectors, failure is usually not due to a single defect, but rather the result of the long-term cumulative effect of structural design, manufacturing processes, and the operating environment. Understanding these failure modes helps to take targeted measures in advance during the design and manufacturing stages, thereby significantly improving the overall reliability of the system.

Solder joint-related failures are one of the most common problems in SMT connectors. Because connectors are typically large and have concentrated mass, solder joints are repeatedly subjected to tensile and shear stresses under temperature cycling or mechanical vibration. If the pad design is unreasonable or the amount of solder is insufficient, micro-cracks can easily form at the root of the solder joint, gradually expanding over long-term use and eventually leading to intermittent open circuits. These types of problems are often difficult to detect during initial functional testing, but gradually emerge after the product is put into use, becoming a significant source of after-sales failures.

Structural failures caused by insertion and removal stress are equally serious. Although SMT connectors are designed for surface mounting, in practical applications, insertion and removal operations inevitably apply additional torque to the solder joints. If the connector lacks sufficient mechanical fixing structures, these forces act directly on the solder joints, accelerating the fatigue process. Therefore, in applications requiring insertion and removal operations, reliability control focuses not only on soldering quality but also on whether the overall connector structure can effectively distribute external forces.

Environmental factors often cause insidious failures. Moisture, dust, or chemical residues can gradually accumulate in the connector contact area, leading to increased contact resistance or unstable electrical performance. For SMT connectors, these problems are more likely to occur in high-humidity or high-temperature environments if surface treatment or material selection is inappropriate. Therefore, in reliability-oriented design, material corrosion resistance and surface protection capabilities are indispensable factors.

In the manufacturing process, process consistency has a direct impact on the reliability of SMT connectors. Connector pads are large and have high heat capacity. If the reflow soldering temperature profile is not properly controlled, insufficient solder wetting or voids can easily occur. These process defects, even if not obvious during visual inspection, can gradually evolve into functional failure over long-term operation. Therefore, connectors often require separate process evaluation and monitoring, and cannot be treated the same as ordinary surface-mount components.

To address these failure risks, the core of reliability control lies in “moving forward.” In the design phase, potential risks are reduced through reasonable pad design, structural reinforcement, and stress dispersion. In the manufacturing phase, soldering consistency is ensured through stable process windows and strict process control. In the verification phase, problems are exposed as early as possible by combining temperature cycling, vibration, and mating life tests. Only by systematically combining these measures can SMT connectors operate stably for long periods in complex application environments.

SMT Connector Selection Logic and Future Development Direction

In practical engineering applications, there is no “universal optimal solution” for selecting SMT connectors. Instead, it is a systematic decision that requires repeated trade-offs between performance, reliability, manufacturing capabilities, and cost. A truly rational selection logic often doesn’t start with parameter lists, but rather works backward from the product lifecycle and usage scenarios to deduce requirements.

First, the application environment is a fundamental prerequisite for selection. The presence of frequent plugging and unplugging, vibration and shock, high humidity, or temperature cycling directly impacts the choice of connector structure and materials. For equipment requiring long-term stable operation, it’s better to invest in higher reliability connection solutions early on than to excessively cut costs at critical connection points. Once a connector becomes a source of failure, the maintenance and repair costs often far outweigh the initial savings.

Second, PCB design and manufacturing capabilities must be considered in tandem with connector selection. SMT connectors are highly dependent on pad precision, stencil design, and reflow soldering processes. If the connector design exceeds actual manufacturing capabilities, even with superior theoretical performance, it will be difficult to achieve stable mass production. Therefore, in engineering practice, it’s often necessary for connector suppliers, PCB manufacturers, and system designers to maintain thorough communication to ensure the design solution is truly feasible.

From a development trend perspective, SMT connectors are evolving towards higher density, lower height, and higher reliability. On the one hand, the continuous miniaturization of electronic products is driving the shrinking of connector pin pitch; on the other hand, the increasing demands for high-speed signals and high power are placing higher requirements on the electrical performance and heat dissipation capabilities of connectors. This seemingly contradictory trend is forcing continuous innovation in connector materials, structures, and manufacturing processes.

Meanwhile, with the improvement of automation and intelligent manufacturing levels,The design of SMT connectors increasingly emphasizes mounting stability and process tolerance. Future connectors will not only need “good performance” but also “easy manufacturing, easy testing, and easy maintenance,” which will become a crucial component of their core competitiveness.

Summary

SMT connectors play a role in modern electronic systems that goes far beyond simply “connecting.” They are not only channels for electrical signals and energy transmission but also critical interfaces between mechanical structures and manufacturing processes. From structural design to application scenarios, from failure modes to selection logic, every detail is magnified over the long term of product operation. Only by viewing connectors as part of system reliability, rather than as independent standard components, can the true value of SMT connection solutions in modern electronic manufacturing be realized.