In this era of rapid technological advancement, autonomous driving is progressively evolving from concept to reality, emerging as a pivotal direction for the automotive industry’s future development. However, for autonomous driving to achieve truly safe and reliable operation, the dependability of its core components—sensors—is paramount. Among numerous technologies enhancing sensor reliability, LTCC technology stands out, leveraging its unique advantages to become a key driver propelling autonomous driving towards higher levels of sophistication.

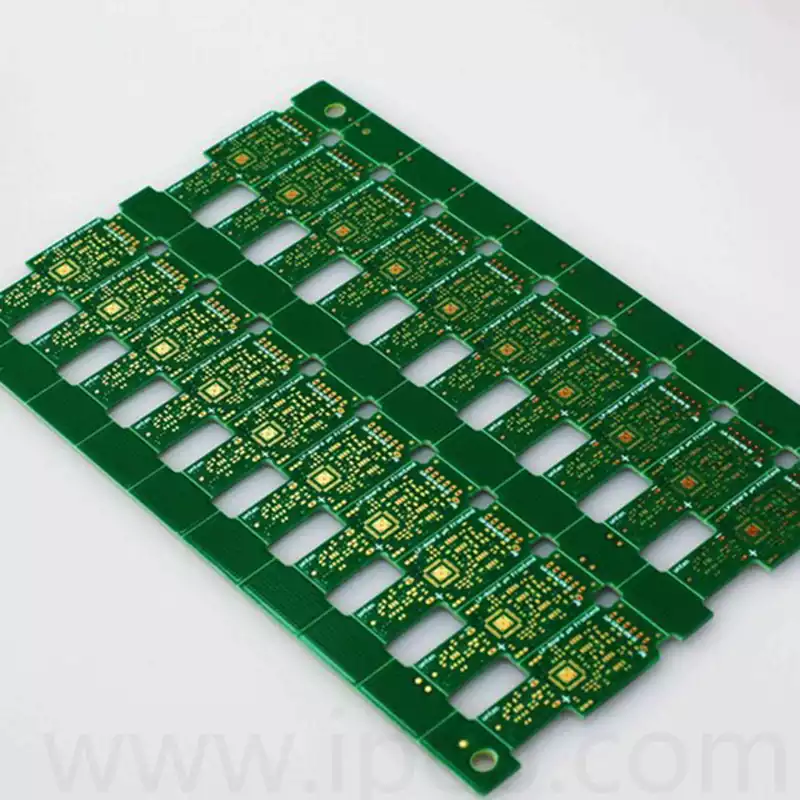

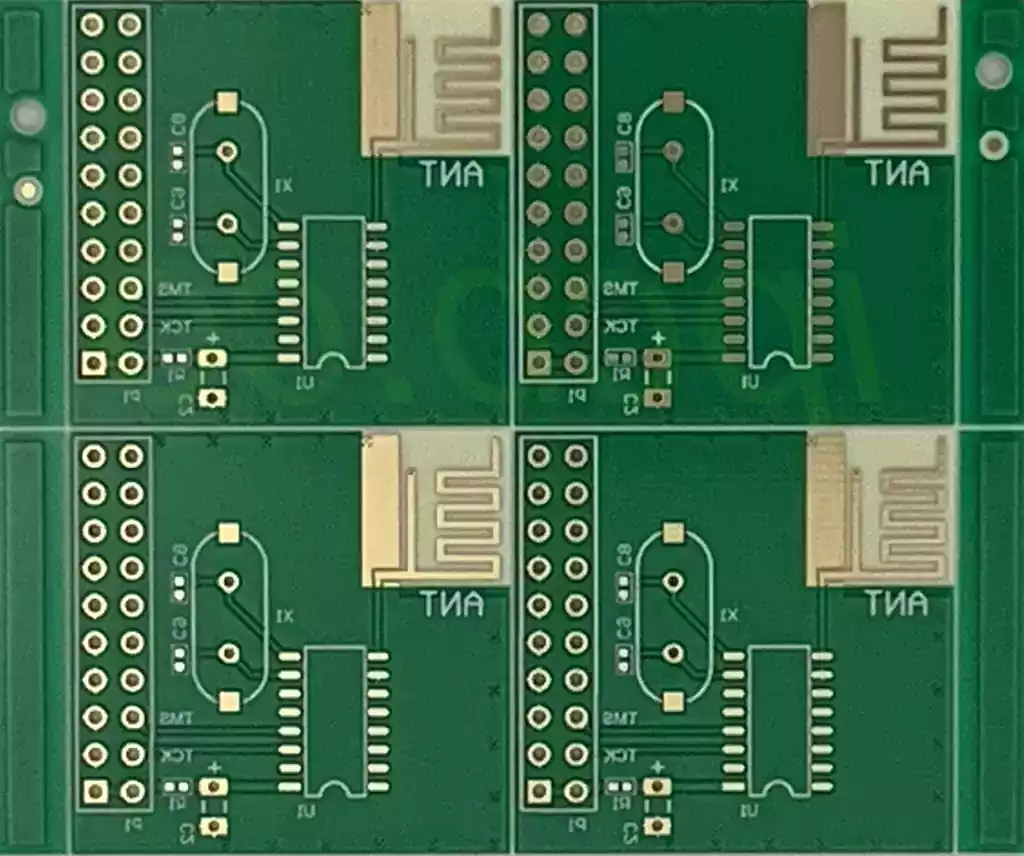

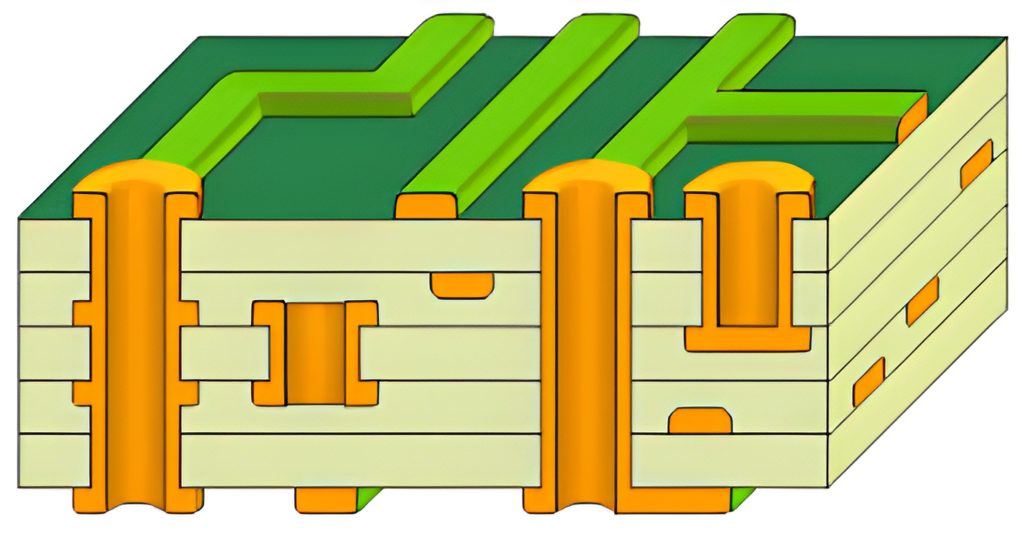

LTCC technology is not a novel concept emerging from nowhere. As early as the 1980s, this technology found application in military communications due to its outstanding performance in high-frequency circuits. Its core principle involves mixing ceramic powder with organic binders to form green ceramic tape. Through processes such as laser drilling, metallised through-holes, and screen printing, multi-layer circuits are formed. Finally, the material is co-fired at a low temperature of 850-900°C to achieve its final shape.

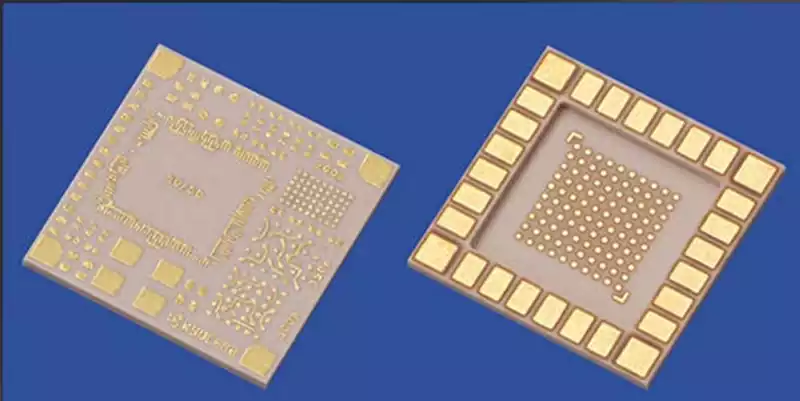

The high reliability of LTCC technology stems from its unique material composition and microstructural design. Compared to traditional packaging materials, LTCC substrates employ a synergistic construction of glass/ceramic composite dielectric and highly conductive metallic conductors. Formed through a low-temperature co-firing process below 950°C, they retain the stability of ceramic materials while balancing process compatibility and electrical performance, perfectly matching the stringent operational demands of autonomous driving sensors.

Regarding thermal stability, the thermal expansion coefficient of LTCC substrates precisely matches that of chips and components. They maintain structural integrity across the extreme automotive temperature range of -40°C to 125°C, effectively preventing encapsulation cracking and signal discontinuity caused by thermal cycling. Winter testing data from a vehicle manufacturer in Heihe indicates that millimetre-wave radar employing LTCC packaging maintained signal attenuation below 3% during 72 hours of continuous operation at -40°C, demonstrating 50% greater stability than conventional packaging solutions. Furthermore, the ceramic substrate’s dense structure and minimal water absorption prevent moisture ingress-induced short circuits even in high-humidity conditions (95% RH) prevalent in southern China, ensuring all-weather sensor operation.

Electrically, LTCC substrates exhibit minimal dielectric loss (with a dielectric constant as low as 4.04 at 15 GHz). Paired with highly conductive metal traces such as gold, silver, or palladium/silver, conductor sheet resistance can be reduced to 0.001–0.01 Ω/□. This effectively minimises energy loss and signal distortion during high-frequency transmission in autonomous driving sensors. This characteristic is crucial for sensors reliant on high-frequency signals, such as millimetre-wave radar and lidar, ensuring precise detection of faint targets at 300 metres and providing reliable data support for advanced autonomous driving decision systems.

The trend towards miniaturisation and multifunctionality in autonomous driving sensors imposes heightened demands on packaging technology’s integration capabilities. LTCC’s high-density integration characteristics not only enhance integration levels but also further bolster reliability performance. Its core advantage lies in enabling multilayer routing designs that embed passive components—such as resistors, capacitors, inductors, antennas, and filters—directly within the substrate, significantly reducing external connection traces and solder joints.

In traditional discrete component packaging solutions, external wiring and solder joints are high-risk failure points, prone to poor contact due to vibration and shock. LTCC’s embedded integration design reduces sensor module solder joints by over 40%, lowering failure rates by the same margin while reducing module weight by 15%. This simultaneously enhances reliability and meets automotive lightweighting requirements. Taking 4D imaging millimetre-wave radar as an example, LTCC technology enables high-density integration of 12 transmit and 16 receive channels. A single chip integrates the RF front-end, analogue-to-digital converter, and signal processor, reducing data processing latency from 10μs to 2μs. It also eliminates electromagnetic interference from external wiring, maintaining 64 simultaneous multi-target tracking capabilities in rain and fog conditions – double that of conventional solutions.

Furthermore, LTCC substrates can be laser-machined to form cavities of diverse geometries, accommodating varied component packaging requirements. Combined with precision thin-film wiring technology, this enables hybrid multilayer substrate designs with enhanced routing accuracy and performance. This flexible structural design capability enables customised packaging solutions for autonomous driving sensors. Whether optimising thermal management for lidar or integrating flicker suppression modules for camera sensors, LTCC technology achieves a balance between reliability and performance.

How LTCC Overcomes Reliability Challenges in Autonomous Driving

Autonomous driving sensors face reliability challenges far exceeding those of conventional electronic devices. Vibrations, impacts, extreme temperature fluctuations, and electromagnetic interference encountered during vehicle operation impose stringent demands on sensor substrates. LTCC establishes a reliability protection network through three key technological breakthroughs:

1.Vibration-Resistant Design: The ‘Flexible Intelligence’ of Rigid Ceramics

Conventional ceramics are prone to cracking in vibrating environments due to high brittleness. LTCC addresses this challenge through innovative formulation design. An LTCC material developed by a supplier exhibits an 80% reduction in crack propagation rate compared to conventional ceramics under 10g vibration acceleration. The secret lies in introducing nano-scale whisker reinforcements into the ceramic matrix, creating a microstructure akin to reinforced concrete. This maintains the ceramic’s high rigidity while significantly enhancing fatigue resistance.

2.Thermal Management Revolution: From Passive Cooling to Active Regulation

Autonomous driving sensors consume 3-5 times more power than conventional devices, making heat dissipation a critical reliability bottleneck. LTCC achieves intelligent thermal management by embedding microchannels and phase-change materials within the substrate. After adopting LTCC substrates, a LiDAR manufacturer reduced sensor operating temperature fluctuations from ±15°C to ±3°C, lowering failure rates by 72%. More advanced designs even integrate thermocouples directly into LTCC layers, enabling real-time temperature monitoring and dynamic regulation.

3.Electromagnetic Compatibility: Building Defences for the 5G Era

With the development of vehicle networking, sensors must simultaneously process multi-band signals including GPS, 4G/5G, and Wi-Fi, making electromagnetic interference a prominent challenge. LTCC achieves outstanding EMC performance through the following designs:

Multi-layer shielding structure: Embedding metallic shielding layers between critical signal layers, achieving isolation exceeding 60dB

Integrated filters: Fabricating bandpass filters directly on the LTCC substrate with insertion loss below 0.5dB

Optimised grounding design: Employing a three-dimensional grounding network to reduce grounding impedance to the milliohm level

As autonomous driving advances towards Level 4 and beyond, sensor requirements for reliability and performance will intensify, driving continuous iteration and optimisation of LTCC technology. Future developments will focus on researching high-performance substrate materials to achieve lower dielectric constants, reduced dielectric loss, and enhanced mechanical strength, thereby meeting emerging technological demands such as 6G communications and AI perception fusion. At the process level, automated precision printing and laser micro-machining will enhance routing accuracy and production consistency, further reducing failure rates. In terms of integration, LTCC will deeply integrate with Through-Silicon Vias (TSV) and System-in-Package (SiP) technologies to achieve unified encapsulation of sensors, processors, and antennas, constructing more compact and reliable sensing units.

The safety boundaries of autonomous driving are invariably defined by sensor reliability. Leveraging triple advantages in materials, structure and process, LTCC technology establishes a core defence line for sensors, enabling them to withstand extreme environments and ensure precise perception. From laboratory breakthroughs to widespread adoption in mass-produced vehicles, LTCC is quietly propelling autonomous driving from technological exploration towards safe implementation, emerging as a critical foundational technology underpinning the era of advanced autonomous driving.