When the thermal conductivity of conventional FR-4 substrates, typically below 1 W/(m·K), proves inadequate for managing the thermal loads of high-power devices, ceramic circuit boards emerge as the preferred solution. Their exceptional thermal performance establishes them as a core component in high-end applications such as new energy vehicles, 5G communications, and medical equipment. As a fundamental performance metric, thermal conductivity not only determines device operational stability but also directly influences the end product’s lifespan and suitability for diverse operational scenarios.

Core Factors Influencing Thermal Conductivity in Ceramic Circuit Boards

The thermal performance of ceramic circuit board is not determined by a single factor but arises from the combined effects of material properties, manufacturing processes, and structural design. These interrelated elements collectively form the core logic governing thermal conductivity in ceramic circuit boards, providing a basis for selecting appropriate materials across diverse applications.

1.Substrate Properties

The crystal structure and composition of ceramic materials form the fundamental basis for thermal conductivity. Significant variations exist in the thermal performance of ceramic substrates made from different materials, which directly defines their applicable scenarios. Diamond holds the highest thermal conductivity in nature, ranging from 1000 to 2200 W/(m·K). However, its high cost and extreme processing difficulty restrict its use to scenarios demanding exceptional heat dissipation. Within commercial ceramic circuit boards, mainstream materials exhibit a distinct thermal conductivity gradient: aluminium nitride (AlN) stands out with 140–240 W/(m·K), making it the preferred choice for high-power applications; silicon carbide (SiC) offers 120–270 W/(m·K), combining high mechanical strength with thermal stability; Silicon nitride (Si₃N₄) offers thermal conductivity between 70–120 W/(m·K), suited to extreme environments due to its outstanding thermal shock resistance and toughness; while the most widely used aluminium oxide (Al₂O₃), with thermal conductivity of 18–35 W/(m·K), possesses limited thermal conductivity but is cost-effective and technically mature, making it suitable for medium-to-low power applications.

Beyond thermal conductivity values, a material’s coefficient of thermal expansion (CTE) significantly influences thermal management efficacy. Aluminium nitride and silicon nitride exhibit CTE values close to silicon (Si), reducing thermal stresses during device operation and preventing structural damage from thermal expansion and contraction, thereby indirectly safeguarding thermal path stability. Ceramics with low thermal conductivity, such as zirconia (ZrO₂), possess thermal conductivities of merely 2–3 W/(m·K). Nevertheless, their exceptional thermal insulation properties render them effective in specialised applications like thermal barrier coatings.

2.Manufacturing Processes

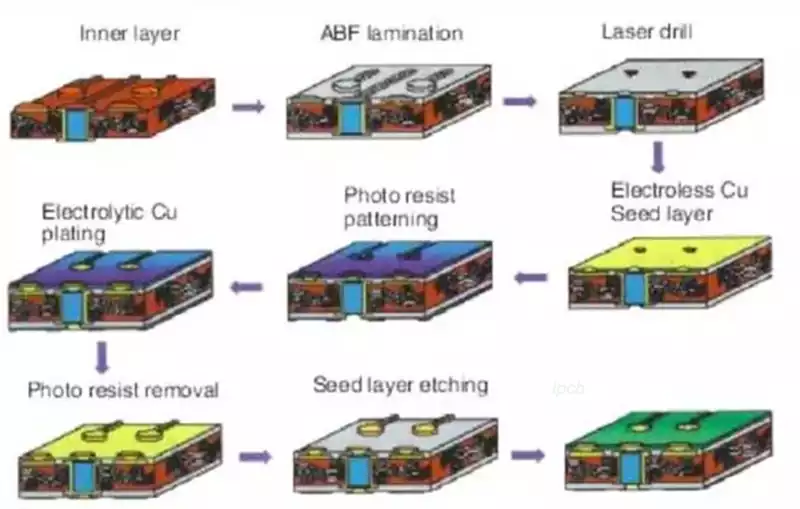

Even with high-thermal-conductivity substrates, process precision critically determines the final thermal performance of ceramic circuit boards. Forming and sintering processes directly influence the substrate’s density, which is key to efficient heat transfer—higher porosity increases heat transfer losses and reduces thermal conductivity. Mainstream tape-casting processes produce large-format substrates with excellent density, suitable for mass production. High-precision techniques like spark plasma sintering (SPS) further enhance substrate density but, owing to higher costs, are predominantly employed for high-end custom products.

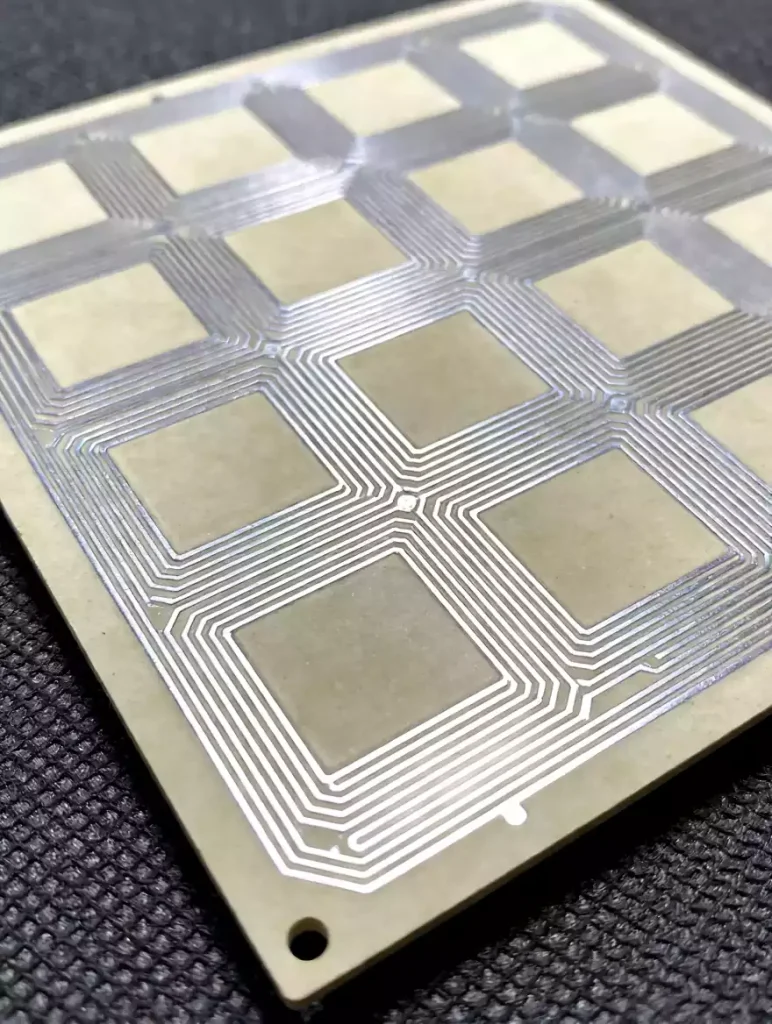

As a core process for ceramic circuit boards, metallisation similarly impacts the integrity of thermal pathways. Processes like Direct Bonded Copper (DBC) and Direct Plated Copper (DPC) achieve tight bonding between the metal layer and ceramic substrate, reducing interfacial thermal resistance and ensuring rapid heat transfer from components to the substrate. DPC, in particular, enables line width/spacing precision within 10μm, simultaneously safeguarding signal transmission and optimising thermal efficiency in 5G high-frequency components. while active metal bonding proves suitable for high-temperature, high-pressure scenarios, enhancing the thermal reliability of ceramic circuit boards. Furthermore, the application of photopolymerisation 3D printing technology enables the construction of three-dimensional heat dissipation channels, boosting substrate cooling efficiency by 30% and further unlocking thermal potential.

3.Structural Design

The structural design of ceramic circuit boards directly determines the length and resistance of heat transfer pathways. Conventional planar structures feature single thermal conduction paths, struggling to meet the demands of ultra-high power density devices. Today, three-dimensional structural design has become the prevailing trend. Through multi-layer interconnections and irregular heat dissipation channels, these designs shorten heat transfer distances and expand heat dissipation areas. For instance, in new energy vehicle IGBT modules, a multi-layer ceramic substrate stack design combined with a metallic heat dissipation layer rapidly disperses substantial heat generated during module operation, reducing device operating temperatures by over 15°C. Concurrently, substrate thickness and circuit layout influence thermal conductivity; rational circuit distribution prevents heat concentration and mitigates localised overheating.

Technical Advancements and Industry Trends in Ceramic Circuit Board Thermal Conductivity

Driven by escalating performance demands across downstream sectors, optimisation and technological innovation in ceramic circuit board thermal conductivity have accelerated, revealing three key trends: high performance, domestic production, and intelligent solutions. This propels the industry’s evolution from a ‘niche material’ to a ‘core foundational material’.

At the material level, high-thermal-conductivity composite substrates have become a key R&D focus. By integrating ceramic-metal-polymer multi-material composites, these address the performance limitations of single materials, enhancing thermal conductivity while optimising interface compatibility. For instance, aluminium nitride-copper composite substrates retain the high thermal conductivity of aluminium nitride while improving substrate toughness and reducing processing complexity. Process-wise, Low-Temperature Co-fired Ceramics (LTCC) and High-Temperature Co-fired Ceramics (HTCC) technologies continue to mature. The integration of photopolymerisation 3D printing with co-firing techniques controls interlayer alignment deviation within 8μm, elevating interconnection success rates to 92% and further optimising thermal pathways.

The ongoing deepening of domestic substitution drives technological upgrades in thermal conductivity. Previously monopolised by firms like Japan’s Kyocera and America’s Rogers in the high-end ceramic circuit board market, domestic enterprises have now achieved breakthroughs in aluminium nitride powder and high-performance ceramic substrates. Companies such as Fulihua and Ningxia Beici offer products 30% cheaper than imports, with domestic substitution rates rising from under 15% in 2020 to 42% by 2024. At the policy level, the Catalogue of Industrial Structure Adjustment (2024 Edition) classifies ceramic substrates as an encouraged project, further promoting collaborative innovation across the industrial chain.

The application of smart manufacturing technologies has effectively reduced the cost of high-thermal-conductivity ceramic circuit boards, driving large-scale adoption. Automated sintering equipment and digital management systems enhance production precision and stability while reducing scrap rates.

Photopolymerisation 3D printing enables ‘mouldless manufacturing’, shortening sample production cycles to 7-10 days and reducing R&D costs by 60%. By 2032, the global ceramic circuit board market is projected to exceed RMB 31.6 billion, growing at a CAGR of 13.62%, with high thermal conductivity products becoming the core growth engine.