Behind the faint light pulses of laser diodes lies an uncompromising demand for substrate material. From the precise detection of autonomous driving lidar to the high-speed transmission of 800G optical modules, each stable emission relies on ceramic circuit board substrates for efficient thermal dissipation and structural precision. Among numerous ceramic substrates, aluminium nitride (AlN) stands as the unrivalled choice for laser diodes. This preference stems not from redundant performance but from its profound alignment with the laser diode’s operational principles.

Laser diodes inherently operate under demanding conditions: peak power reaching 210W, an operating temperature range spanning -45°C to 85°C, and thermal flux densities exceeding 50W/cm². Conventional substrates simply cannot withstand such extreme conditions. Aluminium nitride substrates precisely meet these operational demands through three core characteristics, establishing themselves as an irreplaceable carrier.

1.Exceptional thermal conductivity, overcoming high-temperature failure

Laser diodes exhibit limited energy conversion efficiency, causing substantial electrical energy to convert into heat concentrated within the chip’s core region. Failure to dissipate this heat promptly leads to rapid junction temperature escalation. This not only induces wavelength drift (with a temperature coefficient of approximately 0.27nm/℃) and output power degradation but can directly burn out the chip. Aluminium nitride substrates exhibit thermal conductivity ≥170 W/(m·K), with premium variants exceeding 240 W/(m·K) – eightfold that of conventional aluminium oxide substrates. This enables rapid establishment of highly efficient thermal pathways.

Thermal resistance data indicates that the bulk thermal resistance of aluminium nitride substrates is merely 0.085 K·W⁻¹ (at 25°C, per ASTM E1461 standard). When combined with the copper layer interface formed via DBC process, the interfacial thermal resistance drops to 0.012 K·W⁻¹, accounting for only 12.4% of the total thermal resistance. This superior thermal management capability maintains the laser diode junction temperature within safe thresholds, extending the operational lifespan of 800G optical modules from three years to over a decade, thereby comprehensively resolving reliability issues stemming from elevated temperatures. In contrast, while tungsten-copper alloys exhibit comparable thermal conductivity, they are prone to internal porosity. Porosity exceeding 2% significantly diminishes thermal efficiency and fails to meet insulation requirements.

2.Precise thermal expansion matching mitigates interfacial stress damage

Laser diode chips predominantly utilise silicon (Si) and indium phosphide (InP) materials, exhibiting thermal expansion coefficients of 3.5×10⁻⁶/℃ and 4.5×10⁻⁶/℃ respectively. Should the thermal expansion coefficients of the substrate and chip differ substantially, repeated thermal cycling induces substantial thermal stresses at the interface. This leads to solder joint cracking and chip delamination, directly causing device failure. The thermal expansion coefficient of aluminium nitride substrates is approximately 4.5×10⁻⁶/℃, highly compatible with chip materials. This minimises structural damage caused by thermal mismatch.

Practical application testing demonstrates that laser diodes packaged using aluminium nitride ceramic circuit boards maintain an interface integrity rate exceeding 99% after enduring thousands of temperature cycles between -40°C and 85°C. whereas products using aluminium oxide substrates (thermal expansion coefficient 7.5×10⁻⁶/℃) or tungsten-copper substrates (thermal expansion coefficient 6.0–8.8×10⁻⁶/℃) exhibited interface cracking rates of 15% and 22% respectively. This thermal matching advantage is critical for demanding applications such as automotive lidar and aerospace laser equipment.

3.High insulation and low dielectric loss ensure pure high-frequency signals

Laser diodes are extensively deployed in high-frequency communication scenarios. 800G/1.6T optical modules demand exceptional signal transmission quality, requiring substrates with outstanding insulation and low dielectric loss. Aluminium nitride substrates exhibit a volume resistivity of 10¹⁴–10¹⁶ Ω·cm, delivering insulation performance far surpassing metallic materials. This eliminates the need for additional insulating structures to achieve circuit isolation, simplifying packaging processes while preventing signal interference.

Regarding dielectric properties, aluminium nitride substrates exhibit a dielectric constant of 8.5–9.0 (at 1 MHz) and dielectric loss below 0.001. This significantly reduces signal attenuation in millimetre-wave and terahertz bands, ensuring synchronous and stable optical-to-electrical conversion for laser diodes. These characteristics establish it as the core substrate material for high-frequency optical modules, laser rangefinders, and similar devices. In contrast, metallic substrates (such as tungsten-copper) cannot meet insulation requirements due to their conductivity and are fundamentally unsuitable for such applications.

The performance of aluminium nitride substrates relies heavily on the support of precision ceramic circuit board manufacturing techniques. Processes such as DBC (Direct Bonded Copper), DPC (Direct Plated Copper), and HTCC (High Temperature Co-fired Ceramics) further optimise the thermal efficiency, circuit precision, and structural stability of these substrates, enabling superior compatibility with laser diodes.

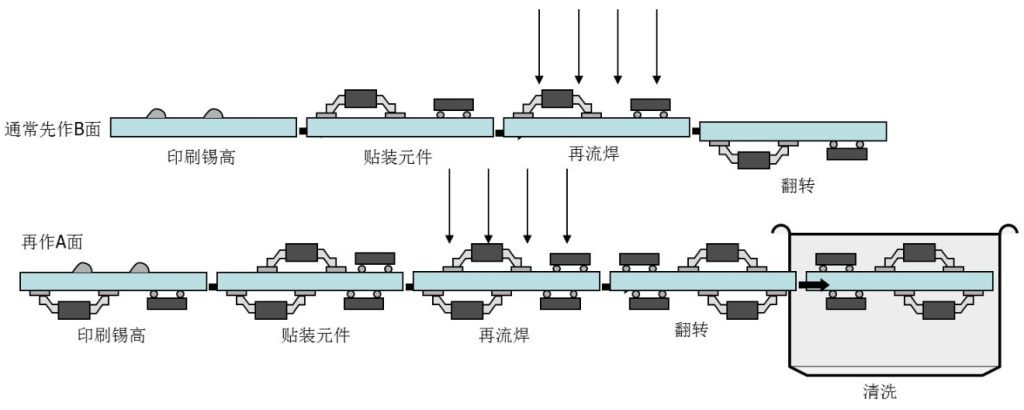

1.DBC/DPC Processes: Optimising Interface Bonding for Enhanced Thermal Management and Precision

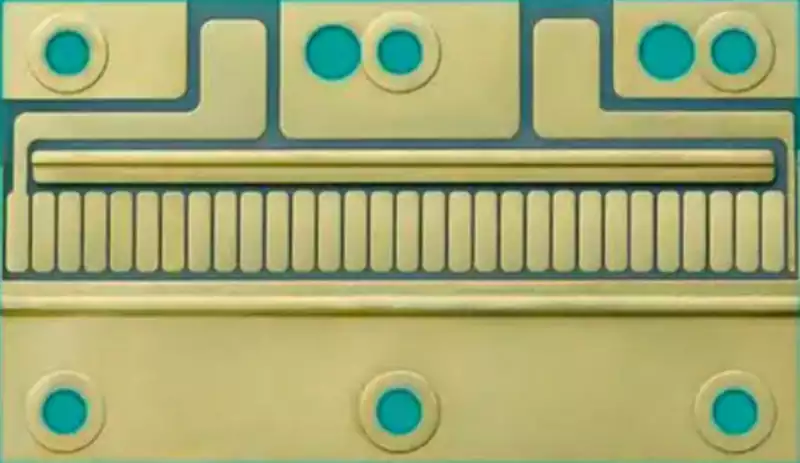

The DBC process forms a Cu-O-Al transition layer (80-120nm thick) at elevated temperatures, achieving a robust bond between the copper layer and the aluminium nitride substrate. This not only reduces interfacial thermal resistance but also enhances the substrate’s mechanical strength, meeting the high-precision soldering requirements of laser diodes. The DPC process employs room-temperature deposition technology, achieving line width/spacing precision within 10μm. In miniature laser diode packaging, this ensures signal transmission efficiency while maximising substrate space utilisation.

For high-power laser diodes, aluminium nitride ceramic circuit boards employing DBC technology can feature copper layers up to 0.3mm thick, further enhancing thermal dissipation capabilities. Conversely, DPC aluminium nitride substrates for micro-laser devices can be coated with Ni/Au layers, improving solder joint oxidation resistance and reliability to extend device lifespan.

2.HTCC Process: Enabling Multi-layer Integration for Complex Requirements

High-Temperature Co-fired Ceramic (HTCC) enables multi-layer circuit integration on aluminium nitride substrates, constructing three-dimensional thermal channels and intricate circuit layouts to meet demands for multi-chip integrated laser diode modules. Aluminium nitride ceramic circuit boards fabricated via HTCC maintain interlayer alignment deviations within 8μm and achieve 92% interconnect success rates. This enables efficient integration of laser diodes, driver chips, detectors and other components, reducing signal transmission paths while enhancing overall thermal dissipation efficiency.

Core Application Domains of Alumina Nitride Ceramic Circuit Boards

1.Autonomous Driving Lidar

The 905nm pulsed laser diode serves as the core component of lidar systems, operating at peak powers ranging from 50 to 210W under conditions of severe vibration and temperature fluctuations. Encapsulation using alumina nitride ceramic circuit boards enables rapid dissipation of transient high temperatures. Concurrently, its thermal matching properties provide resilience against vibration impacts, ensuring stable detection accuracy. Among mainstream LiDAR manufacturers’ products, AlN substrate penetration exceeds 90%, with individual vehicle applications requiring 3-5 substrates.

2.High-Frequency Optical Communication Modules

Laser diode arrays in 800G/1.6T optical modules exhibit extremely high thermal flux density, demanding stringent heat dissipation and signal purity. Alumina ceramic circuit boards maintain component stability through efficient thermal management, while their low dielectric loss characteristics safeguard high-frequency signal transmission, establishing them as the core enabler for optical module upgrades. Global demand for 800G optical modules is projected to reach 18 million units by 2025, driving demand for aluminium nitride ceramic substrates beyond 3 million units. This figure is expected to increase to 10 million units by 2026.

3.Medical and Industrial Lasers

Laser diodes in medical laser equipment (such as laser therapy devices) require long-term stable operation with stringent safety requirements; industrial cutting lasers face high-temperature, high-power operating conditions. AlN ceramic circuit boards, with their high reliability and thermal conductivity, ensure treatment precision in medical lasers while extending the service life of industrial lasers and reducing maintenance costs.

Aluminium nitride ceramic circuit boards serve as a critical foundation for stable laser diode operation, owing to their exceptional thermal conductivity, precise thermal expansion matching, and high insulation with low dielectric loss. As related manufacturing processes continue to be refined and application domains expand, these boards will play an increasingly vital role within the laser diode industry, driving advancements towards higher performance and greater reliability across diverse sectors.