In the intricate world of electronics, the keyboard motherboard is a fundamental component that ensures the seamless functioning of modern keyboards, particularly those used in high-performance and mechanical applications. As keyboards have evolved from simple typing devices to sophisticated tools for gamers, coders, and professionals, the importance of a well-designed motherboard has never been greater. This article delves into the role of the keyboard motherboard, the challenges in its design, and the critical factors that make it a cornerstone of modern keyboard technology.

The Role of the Keyboard Motherboard

At its core, a keyboard motherboard is the central hub that connects all the individual components of a keyboard. It is responsible for translating each keypress into a signal that the computer can understand, managing the power distribution, and, in many cases, controlling the lighting and additional features of the keyboard.

For mechanical keyboards, which are renowned for their tactile feedback and precision, the quality of the motherboard is especially critical. A well-designed keyboard motherboard ensures that each keystroke is registered accurately and consistently, providing the user with a responsive and reliable typing experience. Furthermore, with the advent of customizable keyboards, the motherboard also plays a key role in supporting programmable macros, RGB lighting, and even wireless connectivity.

Challenges in Keyboard Motherboard PCB Design

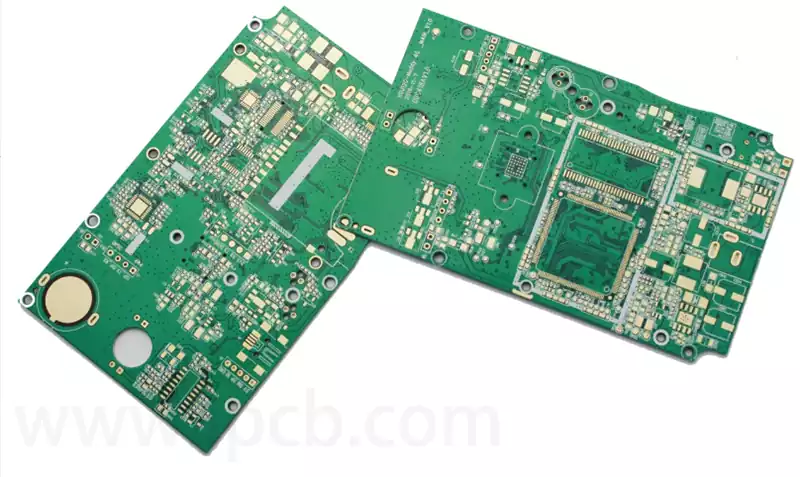

Designing a printed circuit board (PCB) for a keyboard motherboard is a complex task that requires careful consideration of several factors.One of the primary challenges is space management.The PCB must accommodate a large number of key switches, often within a compact form factor,without compromising on the quality of signal transmission.

Additionally, the PCB must be designed to minimize signal interference and ensure that the electrical pathways between components are optimized for speed and reliability. This is particularly important in gaming keyboards, where even the slightest delay in signal transmission can be the difference between victory and defeat.

Another challenge lies in supporting the increasing demand for customization in keyboards. Users today expect features like programmable keys, customizable RGB lighting, and different switch options. The PCB must be versatile enough to support these features while maintaining the overall integrity and performance of the keyboard.

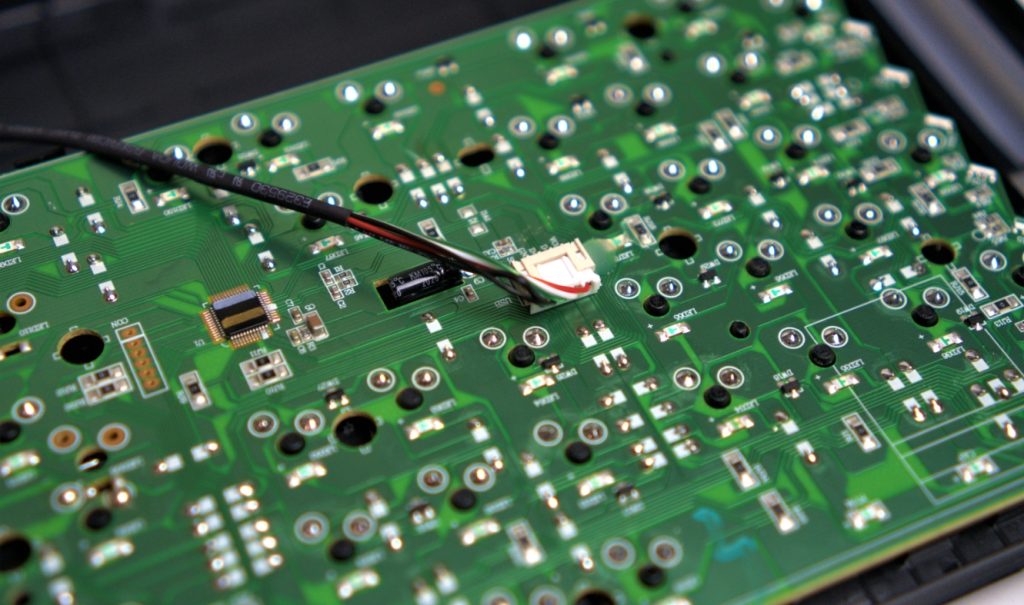

Moreover, as wireless keyboards gain popularity, the need for efficient power management and stable wireless communication adds another layer of complexity to the design of keyboard motherboards . These PCBs must be able to manage power consumption effectively to maximize battery life while ensuring that wireless signals remain strong and interference-free.

Key Considerations in Manufacturing Keyboard Motherboard PCBs

When it comes to manufacturing PCBs for keyboard motherboards, several key considerations come into play to ensure the end product meets the high standards required for modern keyboards:

- Material Selection: The choice of materials used in the PCB is crucial, particularly in terms of durability and thermal stability. High-quality materials that can withstand prolonged use and exposure to varying temperatures are essential for ensuring the longevity and reliability of the keyboard.

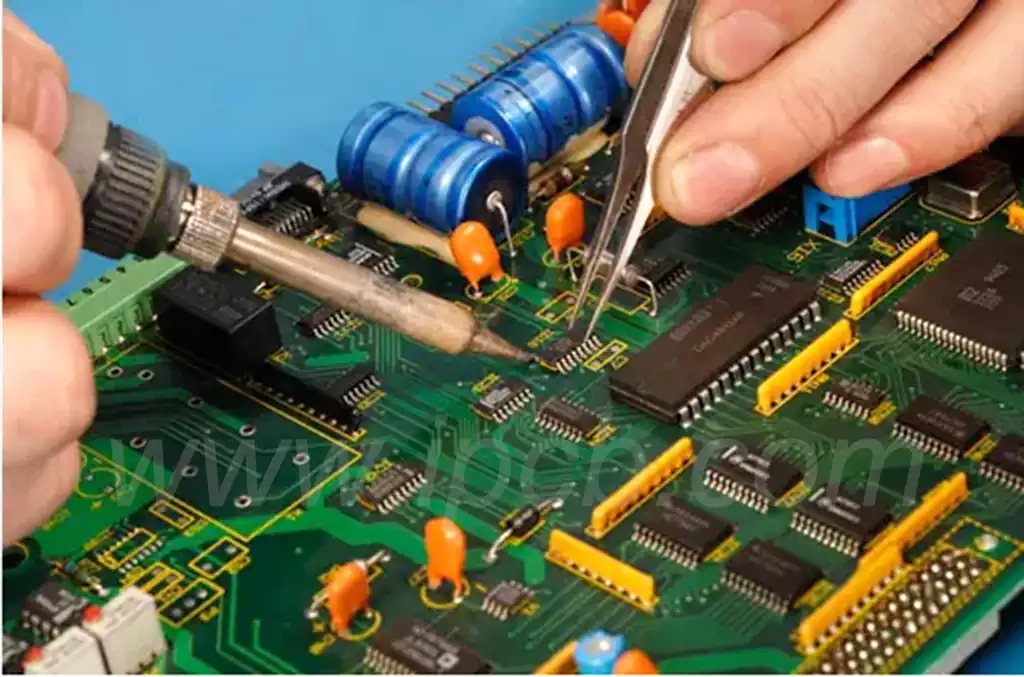

- Precision and Accuracy: The manufacturing process must be precise to ensure that each connection on the PCB is made accurately. This precision is vital for ensuring that the keyboard performs reliably, with each keypress registering as intended.

- Signal Integrity: Maintaining signal integrity across the PCB is essential for ensuring that there is no loss or delay in the transmission of keypress signals. This involves careful routing of electrical traces and the use of appropriate shielding and grounding techniques.

- Customization Capabilities: As mentioned earlier, modern keyboards often require a high degree of customization. The PCB must be designed with this in mind, allowing for features like customizable RGB lighting, programmable keys, and different switch types to be easily integrated.

- Quality Control: Rigorous quality control processes are necessary to ensure that each PCB meets the required standards before it is used in a keyboard. This includes testing for electrical performance, durability, and overall functionality.

The Future of Keyboard Motherboard PCBs

The future of keyboard motherboard PCBs is likely to see further advancements as the demand for more sophisticated and feature-rich keyboards continues to grow. Innovations in materials science, signal processing, and manufacturing techniques will likely lead to even more compact, efficient, and powerful PCBs.

For instance, as the trend towards wireless keyboards continues, there will be a growing emphasis on developing PCBs that are optimized for low power consumption while maintaining high performance. Similarly, advancements in flexible PCBs could pave the way for more ergonomic and customizable keyboard designs, allowing for greater user comfort and a more personalized typing experience.

In addition, the integration of smart features, such as biometric sensors and AI-driven customization, may become increasingly common in keyboards, requiring even more sophisticated PCB designs. These features could enable keyboards to adapt to individual user preferences automatically, further enhancing the overall user experience.

Conclusion

The keyboard motherboard is an essential component that plays a pivotal role in the performance and functionality of modern keyboards. From managing signal integrity and power distribution to supporting advanced features like customizable lighting and wireless connectivity, the PCB of a keyboard motherboard is the backbone that ensures everything works seamlessly.

As technology continues to advance, the design and manufacturing of keyboard motherboard PCBs will need to evolve to meet the increasing demands of users. By understanding the challenges and key considerations involved in creating these PCBs, manufacturers can continue to produce keyboards that not only meet but exceed user expectations, delivering precision, reliability, and innovation in every keystroke.