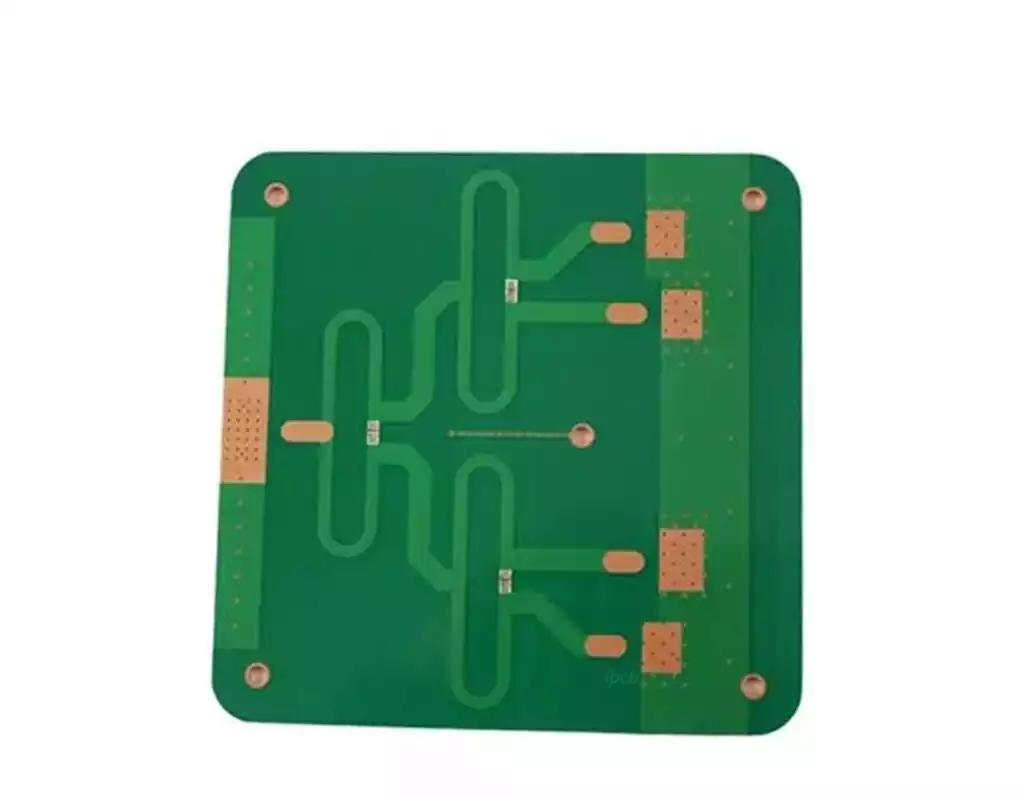

Antenna PCB, also known as Antenna Printed Circuit Board, is a special type of printed circuit board on which the antenna is designed and manufactured for the transmission and reception of wireless signals. Antenna PCB is an important part of a wireless communication system, which realizes wireless communication by converting electromagnetic energy into wireless signal or wireless signal into electromagnetic energy. The working principle of the antenna is based on the principle of electromagnetic radiation and reception, using the electromagnetic field generated by the current in the conductor to realize the transmission of signals.

What is PCB antenna

PCB Antenna (PCB Antenna) refers to an antenna manufactured using PCB (Printed Circuit Board) technology. It is a special type of printed circuit board in which a portion of the copper foil is etched away to form a specific shape of the antenna. This antenna can be integrated directly into the PCB, making the whole system more compact and lightweight.

PCB antenna offers a variety of advantages, such as low cost, ease of fabrication, ease of integration, high reliability, and stability. In addition, PCB antenna can be designed optimally to achieve customized performance parameters to meet the needs of different applications.

Antenna PCB has a wide range of applications. According to their characteristics and performance, they are used in a variety of wireless communication devices and systems, such as cell phones, wireless NICs, Bluetooth devices, GPS navigators, wireless routers, and so on. These devices use antenna PCBs to realize the reception and transmission of wireless signals to meet various communication needs.

The length of an antenna is usually related to its operating frequency. For example, for 2.4 GHz wireless communication, the length of the antenna is usually around 125mm. The length of an antenna operating in the 5 GHz band will be shorter. However, the length of an antenna is not always fixed; it may vary depending on factors such as the shape of the antenna, its design, its mode of operation, and the materials used.

Antennas can be categorized in a variety of ways, and one common way is to categorize them based on their shape. For example, common antenna shapes include dipole antennas, monopole antennas, and microstrip antennas. In addition, antennas can also be categorized according to their directionality, gain, bandwidth, and other parameters. Different antenna types are suitable for different application scenarios and need to be selected according to specific needs.

The materials are mainly of the following types:

FR-4: FR-4 is a glass fiber-reinforced epoxy resin-based material, which is one of the most commonly used PCB materials. It has good mechanical strength, heat resistance, and chemical resistance, as well as good electrical properties and processing performance.FR-4 material has a wide range of applications, including communication equipment, computers, consumer electronics, automotive electronics, and other fields.

Metal substrate: Metal substrate is a metal-based PCB material, commonly used metal substrates include aluminum, copper, tungsten, and so on. The metal substrate has good heat dissipation performance and mechanical strength, suitable for the manufacture of high-power electronic products. Applications of metal substrates include LED lighting power modules, automotive electronics, and other fields.

Ceramic Substrate: A ceramic substrate is a kind of circuit PCB material based on ceramic materials such as alumina and silicon nitride. It has good high-temperature resistance, corrosion resistance, and mechanical strength, and is suitable for the manufacture of high-frequency, high-power electronic products. Applications of ceramic substrates include microwave communications, satellite communications, radar, and other fields.

Polymer substrate: Polymer substrate is a kind of PCB material based on polyimide, polyamide, and other polymer materials. It has good high-temperature resistance, chemical resistance, and mechanical strength, and is suitable for the manufacture of high-performance electronic products. The applications of polymer substrate include aerospace, defense and military industry, medical equipment, and other fields.

Manufacturing points:

Material selection: Materials suitable for high-frequency signal transmission, such as FR4 materials, need to be used. These materials have low dielectric constant and loss, and can effectively transmit high-frequency signals.

Line layout: In the manufacturing process of antenna PCB, the layout of the line is very important. Other electronic components on the antenna board must be reasonably laid out to reduce interference and improve the quality of signal transmission. At the same time, the antenna part should be separated from other circuit blocks, and it is better to place it close to the edge of the PCB to reduce interference and signal loss.

Strict environmental control: During the manufacturing process, environmental factors such as temperature, humidity, and static electricity need to be strictly controlled to avoid any impact on the performance of the antenna board. At the same time, the cleanliness of the fabrication process should be ensured to minimize the effects of stray inductance and capacitance.

Grounding treatment: In the grounding treatment of the antenna, the firmness and conductivity of the grounding point must be ensured to realize good signal transmission. Meanwhile, measures should be taken to minimize the noise interference on the ground plane to improve the signal-to-noise ratio of the antenna.

For the material requirements of the antenna PCB, materials with good conductivity and high-temperature resistance should be selected to meet the requirements of the antenna’s working environment. In addition, the selection of materials should also consider factors such as cost and processability.

Antenna PCB, as a pioneer in leading the field of wireless communication, is characterized by high performance, miniaturization, and low cost, which makes it widely used in wireless communication devices. With the development of emerging technologies such as 5G and IoT, its application prospects will be even broader, making greater contributions to the progress of wireless communication technology.