On a circuit board, RT usually stands for Thermistor, a component that is extremely sensitive to temperature. The resistance value of a thermistor changes significantly with temperature, so by measuring its resistance value, we can accurately deduce the current ambient temperature. This characteristic makes thermistors play a vital role in circuit functions such as temperature detection, temperature control and over-temperature protection.

The operating principle of thermistors includes the PTC effect and the application of semiconductor materials.The PTC effect is the property of a material to increase its resistance value when the temperature increases, and this effect is known as the positive temperature coefficient effect. Most metallic materials possess this PTC effect. The non-linear PTC effect, on the other hand, occurs in materials that undergo a phase change, and these materials experience a sharp increase in resistance over a narrow temperature range.

Polymer PTC thermistors are particularly useful in overcurrent protection. Often referred to as self-resetting fuses, they have a positive temperature coefficient resistance characteristic that makes them ideal for overcurrent protection. Under normal operating conditions, their temperature is close to room temperature and their resistance is low. However, under overcurrent conditions, the resistance increases rapidly and dramatically to limit the current, enabling over-temperature and overcurrent protection.

Semiconductor and metal thermistor materials also each have their advantages. For example, strontium barium acid ceramics are an ideal semiconductor material for positive resistance temperature coefficients, and sensors made from these materials are extremely sensitive due to their high resistance temperature coefficients. Metal thermistor materials, on the other hand, are suitable for high-precision temperature measurement applications.

Thermistors can be classified into two types, positive temperature coefficient thermistors (PTC) and negative temperature coefficient thermistors (NTC), based on the characteristics of the change in resistance value with temperature. The resistance value of a positive temperature coefficient thermistor increases with increasing temperature, while the resistance value of a negative temperature coefficient thermistor decreases with increasing temperature. This characteristic of resistance change enables thermistors to play an important role in temperature measurement, temperature control, overheat protection, and other fields.

Thermistors have the following main features:

High sensitivity: its resistance temperature coefficient is much higher than that of metals, and it can respond quickly to small temperature changes.

Wide temperature range: the operating temperature range is very wide, conventional devices are suitable for -55 ℃ to 315 ℃.

Small size: compact size, suitable for measuring the temperature in small spaces or organisms.

Flexible use: Resistance values can be selected from 0.1 to 100kΩ to meet different needs.

Easy processing and mass production: due to the easy processing of materials and mature production process, it is easy to mass production.

Stable and capable of overload protection: Capable of stable operation in a variety of environments and can withstand a certain degree of overload.

Thermistors have a variety of applications. They are widely used as a way to measure temperature in many different liquid and ambient air environments as thermistor thermometers. Some of the most common uses for thermistors include:

Digital thermometers (thermostats)

Automotive applications (measuring oil and coolant temperatures in cars and trucks)

Household appliances (such as microwaves, refrigerators, and ovens)

Circuit protection (i.e. surge protection)

Rechargeable batteries (to ensure correct battery temperature is maintained)

Measuring thermal conductivity of electrical materials

Temperature compensation (i.e., maintaining resistance to compensate for effects caused by temperature changes in another part of the circuit)

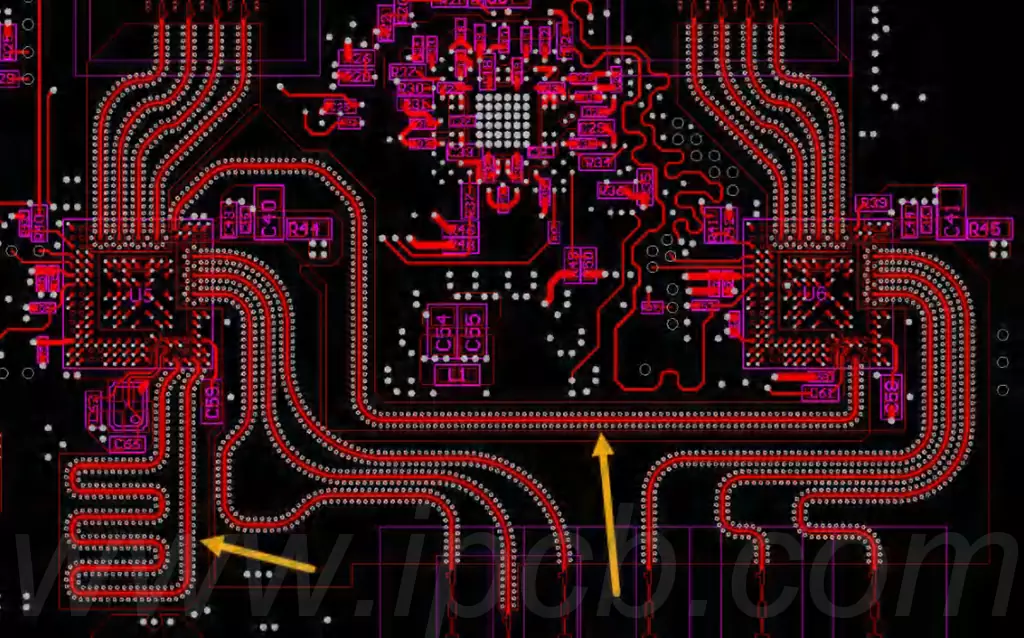

Circuit Board RT Manufacturing Process

The manufacturing process for circuit board RTs, i.e., circuit boards with integrated thermistors, involves a number of core aspects to ensure the performance and reliability of the final product.

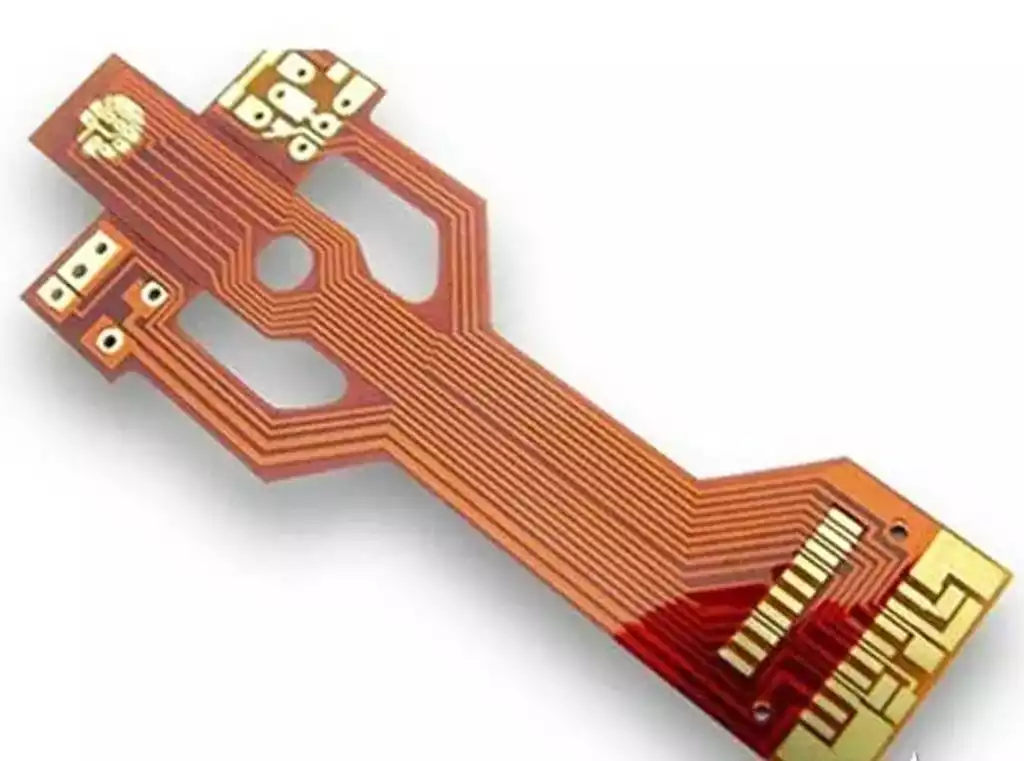

Material Selection and Substrate Preparation

Firstly, the manufacture of circuit board RTs requires the precise selection of suitable thermistor materials and substrate materials. The thermistor material usually requires high sensitivity and stability, while the substrate material must exhibit excellent thermal and electrical conductivity.

Electrode Formation

Next, the precise location of the thermistor is marked on the selected substrate and the electrodes connected to it are constructed. The key to this step is to ensure a solid and efficient connection between the electrodes and the thermistor to minimise losses in signal transmission.

Thermal Layer Application and Hardening

Next, the prepared thermistor material is uniformly applied to the surface of the circuit board on which the electrodes have been fabricated and subsequently cured. In this process, strict control of the coating thickness and uniformity is crucial, which is directly related to whether the thermistor can achieve the expected performance indicators.

Precision Cutting and Performance Verification

After the curing is completed, the circuit board is cut to separate it into individual thermistor modules. These modules are then subjected to a series of performance tests to screen out products that meet quality standards.

Finished Product Encapsulation and Logistics

Finally, the tested thermistors are encapsulated, designed to provide protection from the external environment. Finally, the finished product is shipped out of the factory according to the customer’s specific requirements.

Thermistors have become an indispensable part of modern electronic circuits due to their unique temperature-sensitive characteristics and diverse applications. With the continuous progress of the manufacturing process, the prospect of its application in various fields will be even broader.