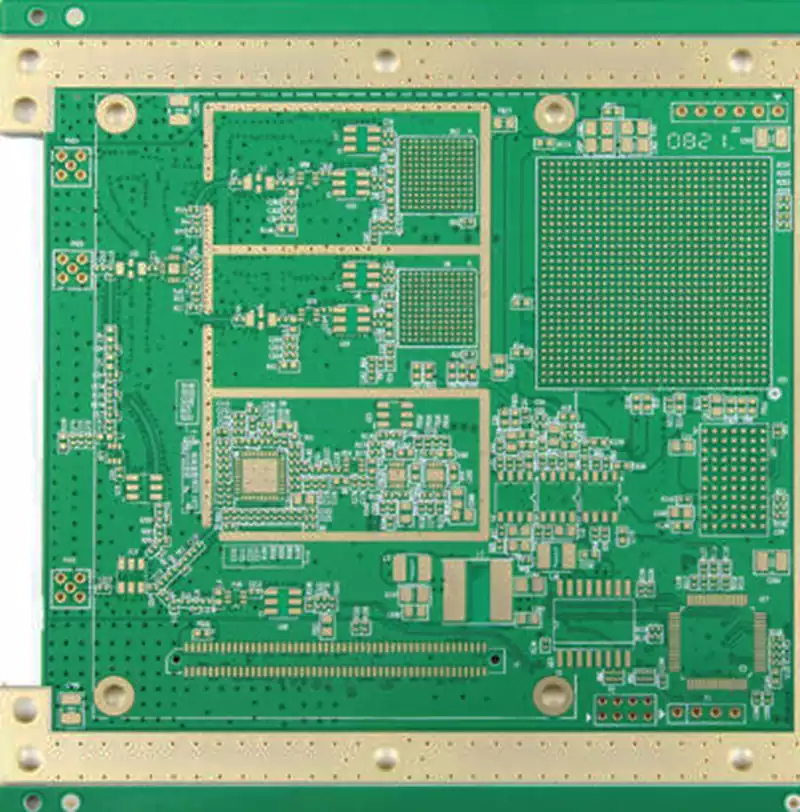

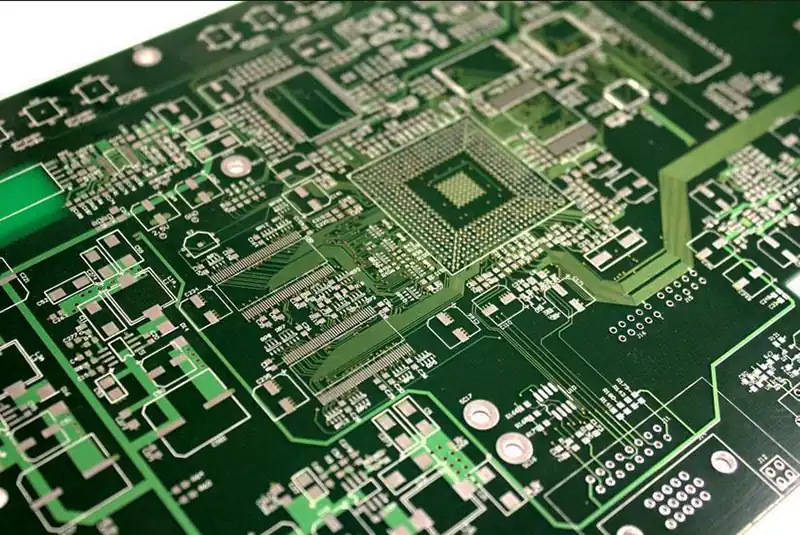

Differences and Selection Between Aluminide and Alumina Ceramic Substrates

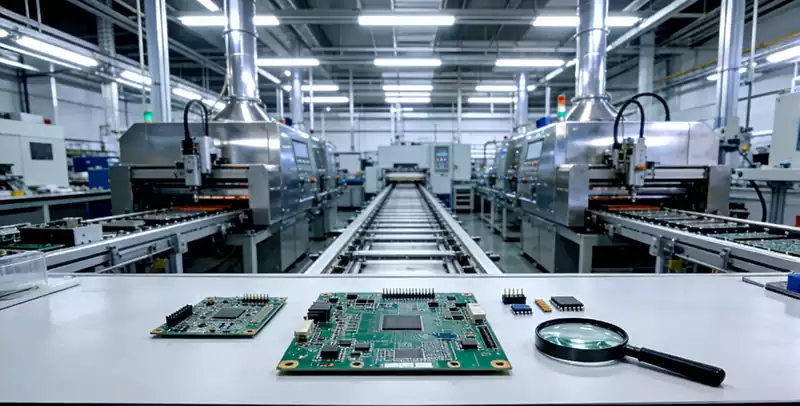

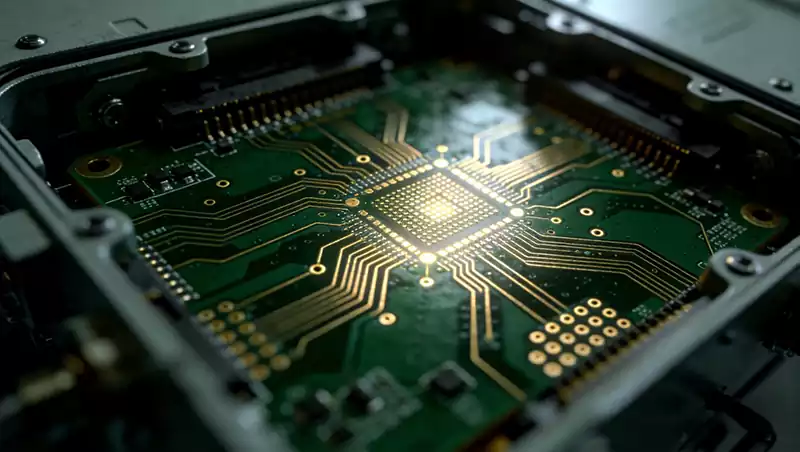

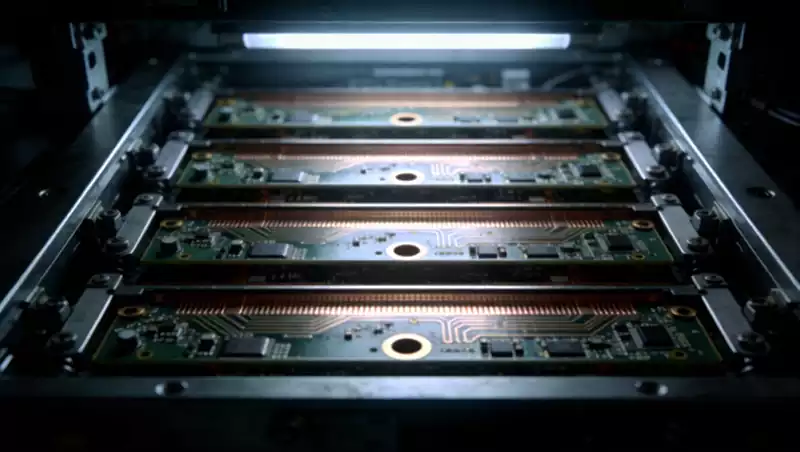

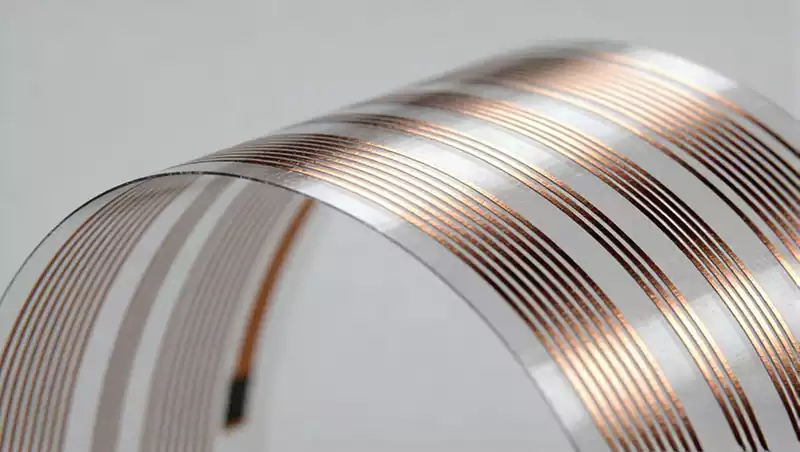

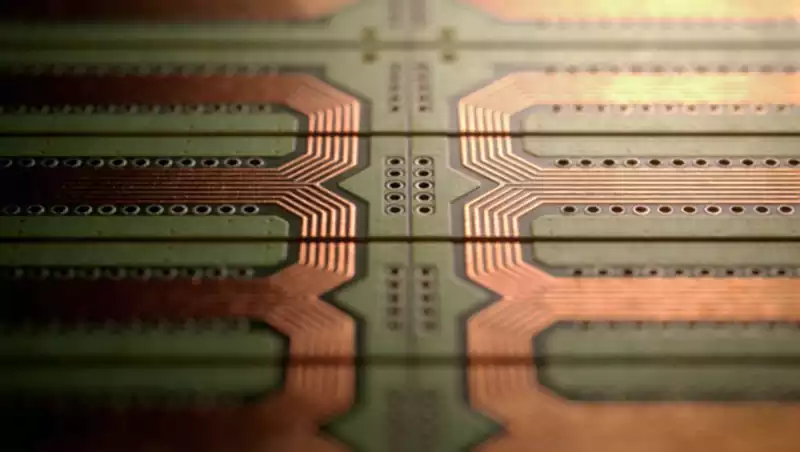

Ceramic substrates, as critically important materials within PCBs, play a pivotal role in enhancing PCB performance through their unique physical and chemical properties. Among these, aluminium oxide (Al₂O₃) and aluminium nitride (AlN) are the two most commonly used ceramic substrates. While they share a similar appearance and overlapping applications, they exhibit significant differences in core […]